Novel container bamboo base plate and manufacturing method thereof

A production method and container technology, applied in the direction of wood layered products, chemical instruments and methods, packaging, etc., can solve the problems of poor floor stability, easy to open the layer, and difficulty in meeting the waterproof requirements of the bottom plate of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

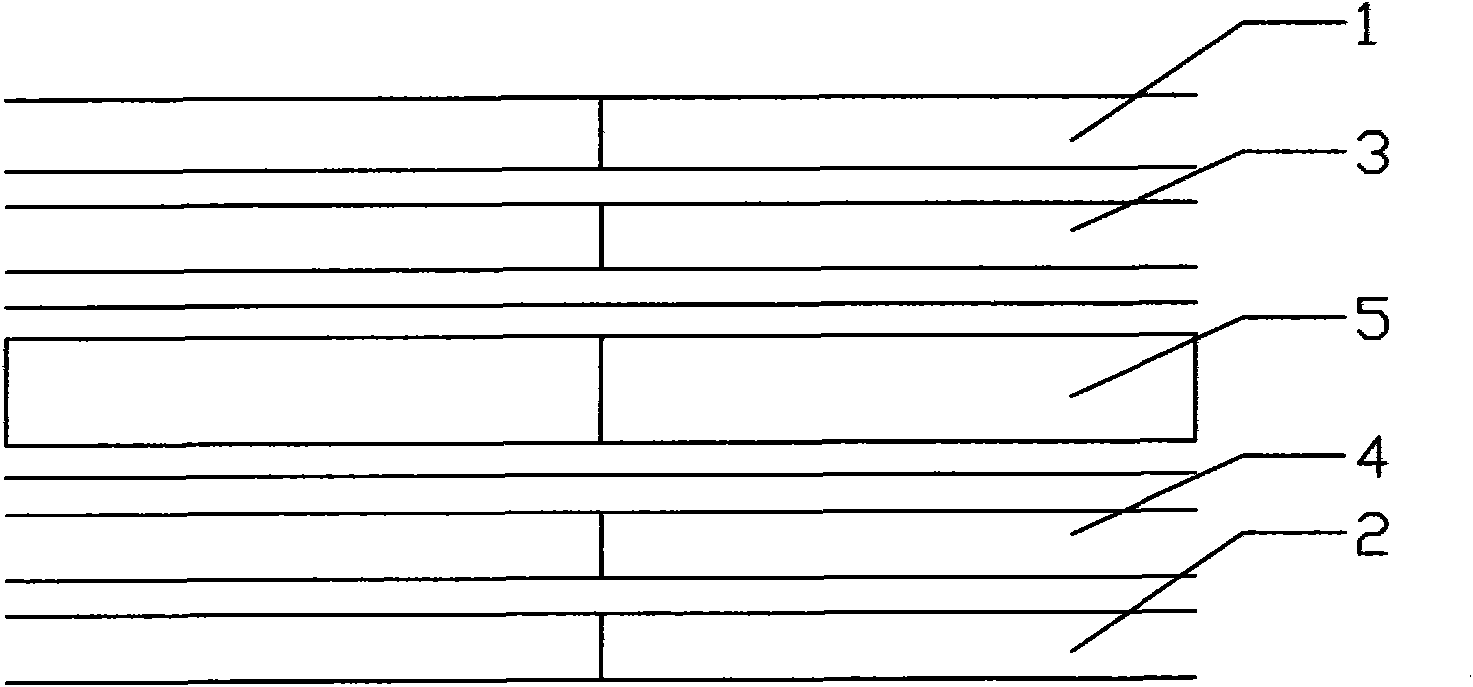

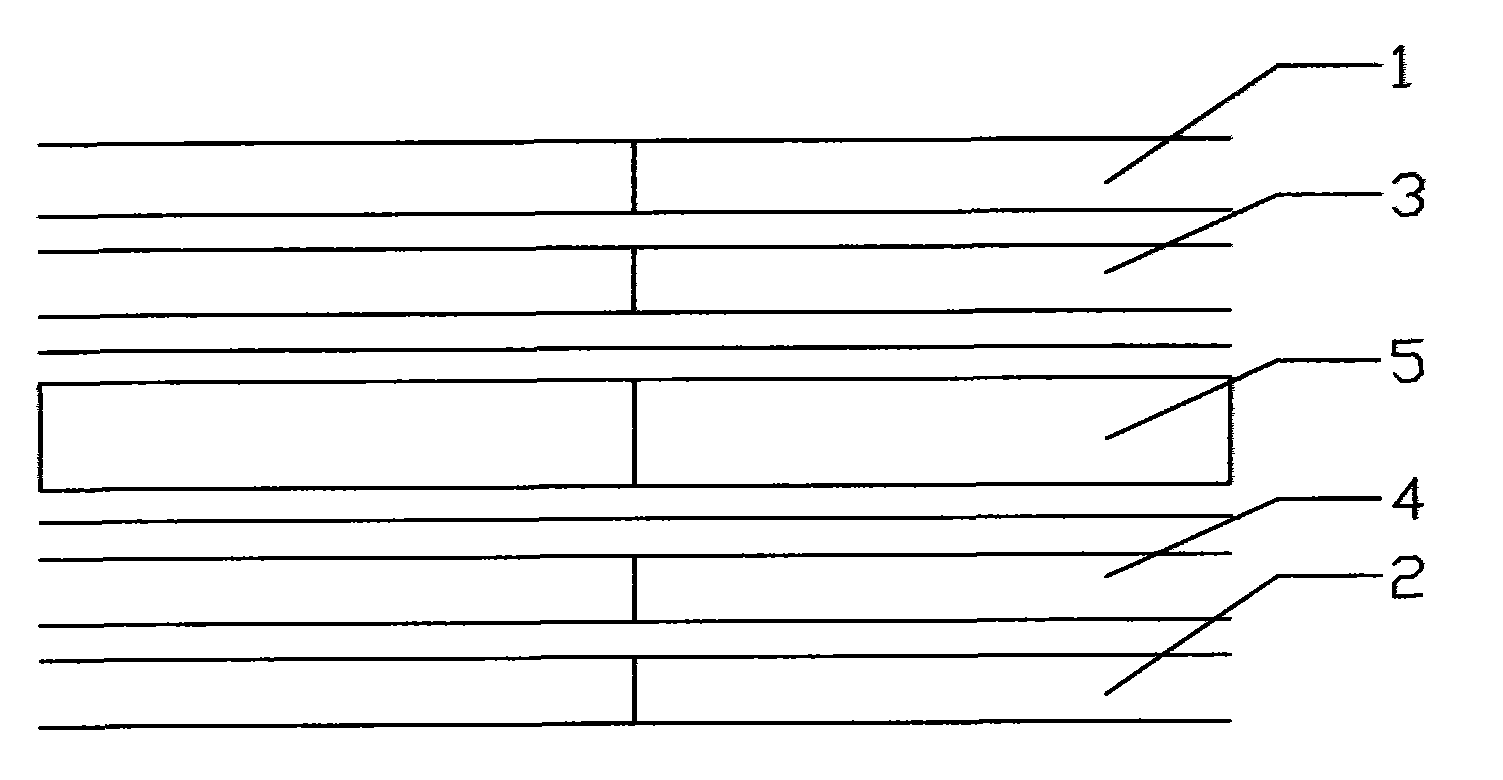

[0028] Embodiment 1: bamboo is broken into thin slices with a thickness of 1.5 mm, and the thin slices are woven into bamboo veneers; the bamboo veneers are first dried, and then the bamboo veneers are dipped in glue, and then the bamboo veneers are After drying, a plurality of bamboo veneers are pre-pressed and hot-pressed at high temperature to become a bamboo plywood substrate; multiple wooden veneers with a thickness of 1.5mm are glued to form a multi-layer wood veneer layer; the bamboo plywood substrate and The multi-layer wood veneer layer blanks are combined to form corresponding base plates, and the base plates become bamboo-wood mixed plywood after being pre-pressed and hot-pressed at high temperature. The plywood produced according to the structure of the method greatly improves the bending strength and stability of the bamboo-wood plywood.

Embodiment 2

[0029] Embodiment two: bamboo is broken into thin slices with a thickness of 1.2mm, and the thin slices are woven into bamboo veneers; the bamboo veneers are first dried, and then the bamboo veneers are dipped in glue, and then the bamboo veneers are After drying, a plurality of bamboo veneers are pre-pressed and hot-pressed at high temperature to become a bamboo plywood substrate; multiple wooden veneers with a thickness of 1.6mm are glued to form a multi-layer wood veneer layer; the bamboo plywood substrate and The multi-layer wood veneer layer blanks are combined into corresponding blanks, and the blanks become the bamboo and wood bottom board of the container after being pre-pressed and hot-pressed at high temperature. After pre-pressing and high-temperature hot-pressing, it becomes a bamboo-wood mixed plywood. The plywood produced according to the structure of the method greatly improves the bending strength and stability of the bamboo-wood plywood.

Embodiment 3

[0030] Embodiment three: bamboo is broken into thin slices with a thickness of 1.1 mm, and the thin slices are woven into bamboo veneers; the bamboo veneers are first dried, and then the bamboo veneers are dipped in glue, and then the bamboo veneers are After drying, a plurality of bamboo veneers are pre-pressed and hot-pressed at high temperature to become a bamboo plywood substrate; multiple wooden veneers with a thickness of 1.7mm are glued to form a multi-layer wood veneer layer; the bamboo plywood substrate and The multi-layer wood veneer layer blanks are combined into corresponding blanks, and the blanks become the bamboo and wood bottom board of the container after being pre-pressed and hot-pressed at high temperature. After pre-pressing and high-temperature hot-pressing, it becomes a bamboo-wood mixed plywood. The plywood produced according to the structure of the method greatly improves the bending strength and stability of the bamboo-wood plywood.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com