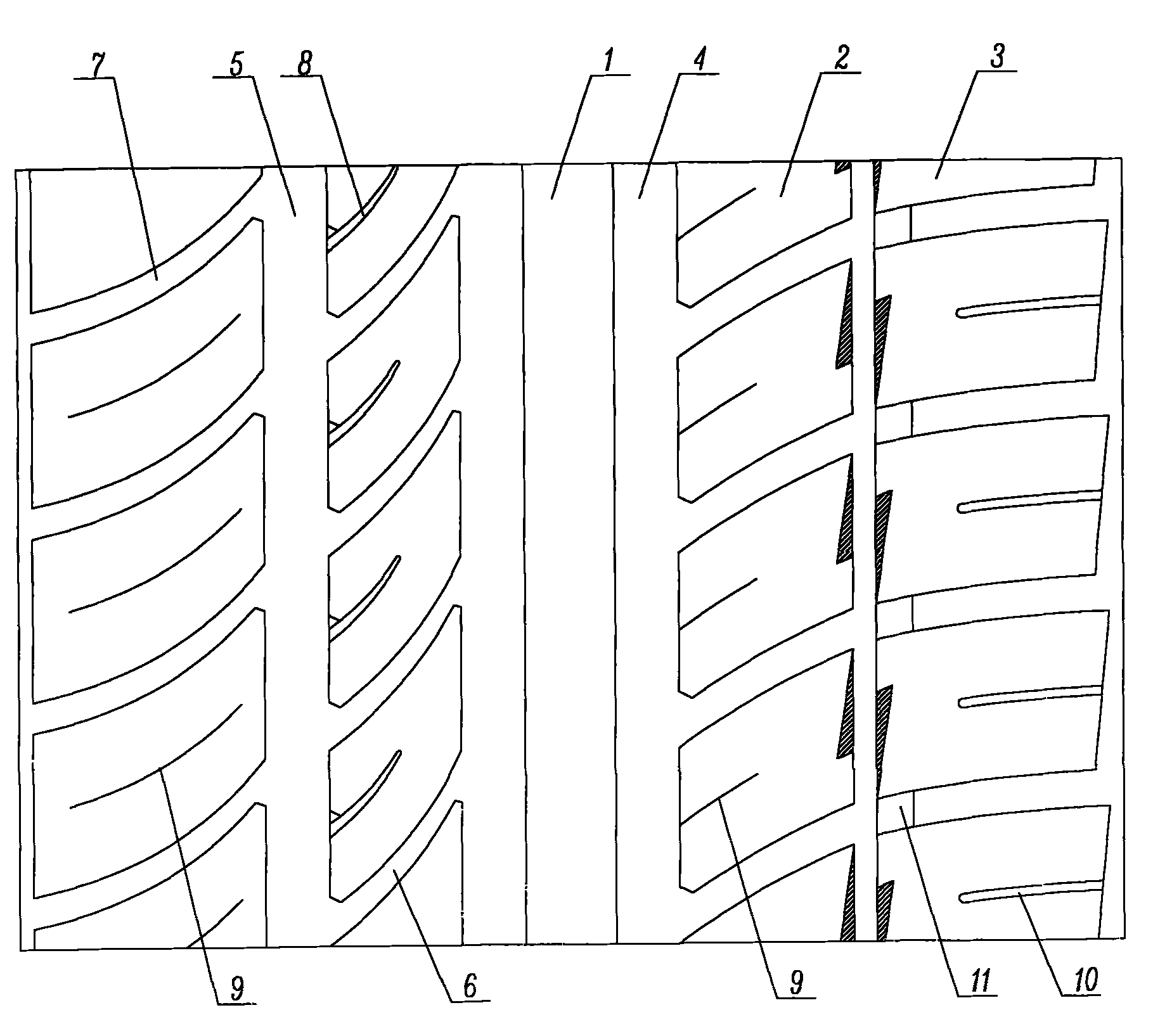

Tread pattern on radial tire of car

A radial tire and tread pattern technology, applied in the direction of tire tread/tread pattern, tire parts, vehicle parts, etc., can solve problems such as the inability to fully meet the ultra-high performance standards of tires, and achieve good high-speed handling stability , Improve stability and steering, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The tire tread of the present invention includes a central pattern block 1, side pattern blocks 2, and shoulder pattern blocks 3, the central pattern block 1 is located in the center of the tread, and the side pattern blocks 2 are regularly arranged in sequence on the left and right sides of the tread from inside to outside. 1. The shoulder pattern block 3, the central pattern block 1 is a longitudinal integrated strip pattern block, the central pattern block 1 and the side pattern block 2 are separated by the main longitudinal circumferential groove 4, and the side pattern block 2 and the shoulder pattern Blocks 3 are separated by auxiliary longitudinal circumferential grooves 5; adjacent side pattern blocks 2 are separated by side grooves 6, and the two ends of side grooves 6 are connected with main longitudinal circumferential grooves 4 and auxiliary grooves respectively. The longitudinal circumferential groove 5 is connected; the adjacent two shoulder pattern blocks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com