Control method and device for rocking arc narrow gap welding system

A welding system and control method technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of low controller control accuracy, single arc shaking track, etc., achieve convenient software programming and real-time upgrade, and low implementation cost Low, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

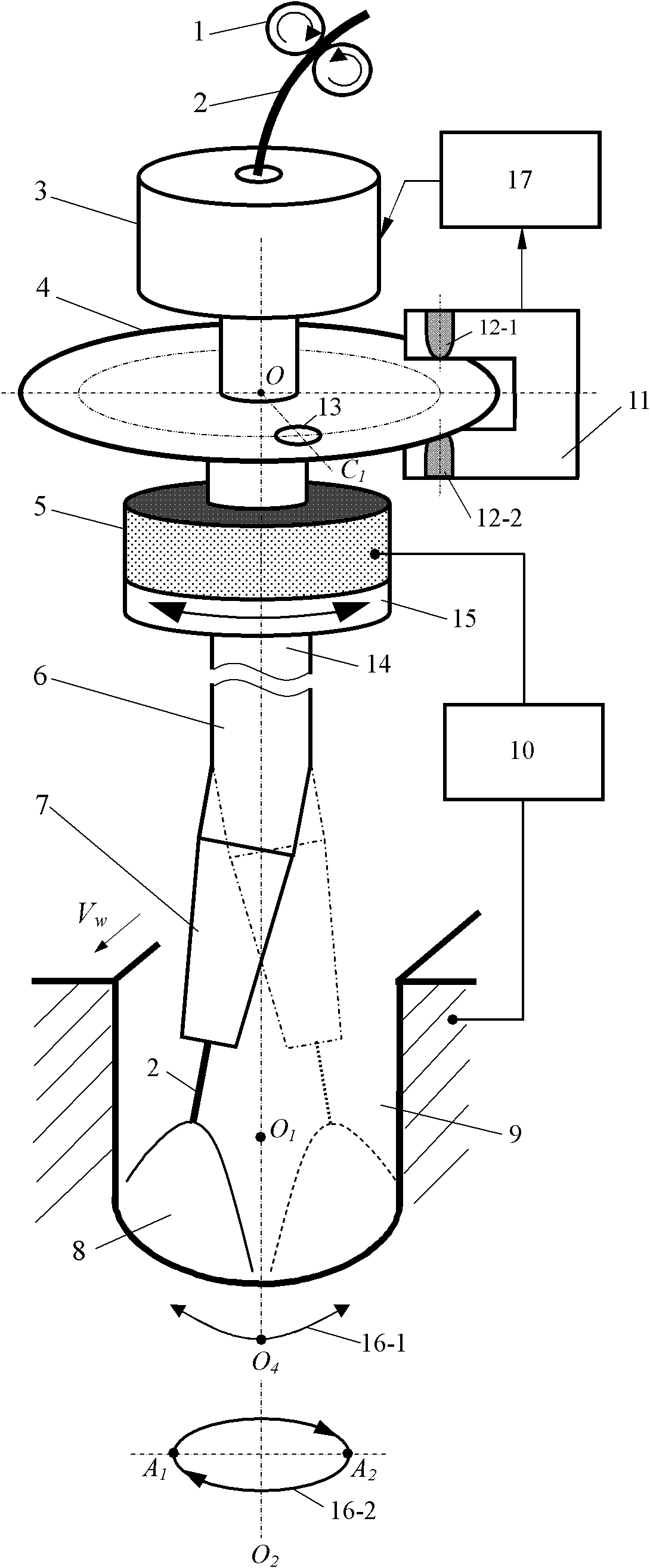

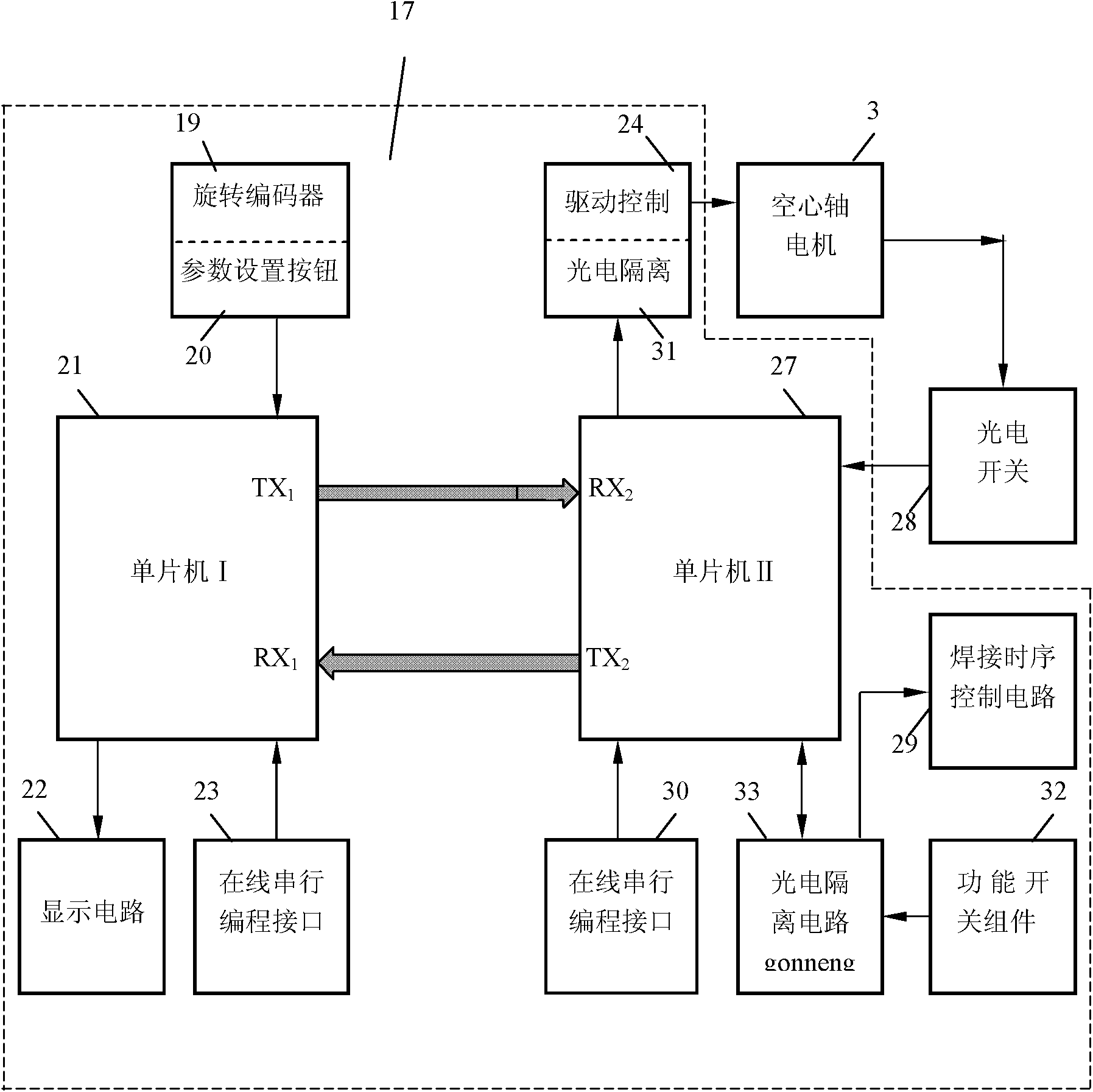

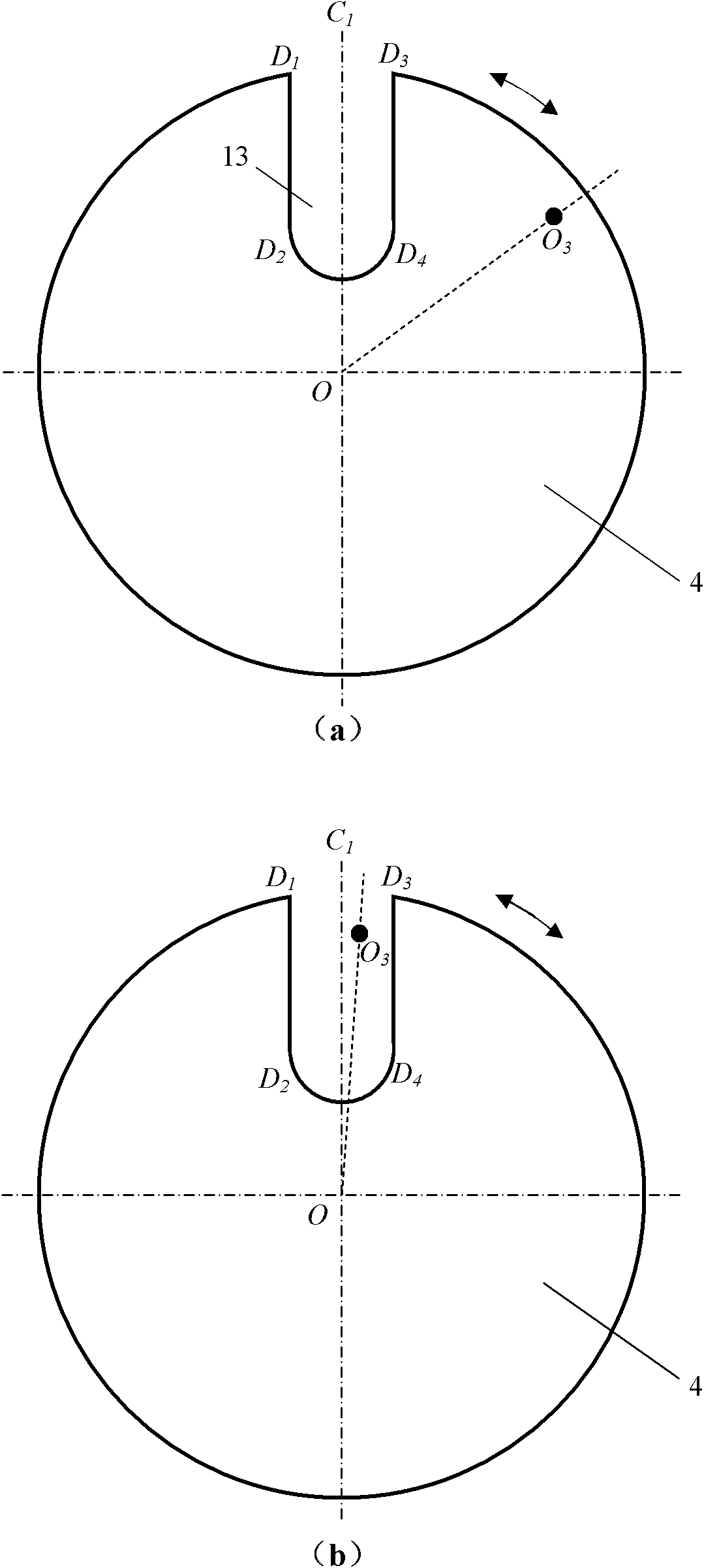

[0025] like figure 1 As shown, the shaking arc narrow gap welding system is composed of a welding torch connected to a controller 17, wherein the welding torch has a straight conductive rod 14, and the straight conductive rod 14 is fixedly sleeved with a hollow shaft motor 3 and a grating from top to bottom. Disc 4 and electric brush 5, the lower end of straight conductive rod 14 is slightly curved conductive rod 6, and the lower end of slightly curved conductive rod 6 is connected to conductive tip 7. The conductive tip 7 extends into the groove 9 to be welded, the upper end of the welding wire 2 is connected to the wire feeder 2, and the welding wire 2 sent out by the wire feeder 1 passes through the straight conductive rod 14, the slightly curved conductive rod 6 and the After the center hole of the contact tip 7, it passes through the center hole of the contact tip 7, and stretches into the groove 9 to be welded to generate a welding arc 8. The grating plate 4 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com