Columnar zinc oxide particles and method for producing same

A technology of zinc oxide particles and particles, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, oxide conductors, etc., can solve problems such as insufficient conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] Example 1 (synthesis of columnar zinc oxide particles)

Synthetic example 1

[0151] (reaction)

[0152] In the mixed solution of zinc chloride aqueous solution and aluminum sulfate aqueous solution with a zinc chloride concentration of 1.011 mol / L and an aluminum sulfate concentration of 0.00505 mol / L, the alkali equivalent ratio is set to 1.2, that is, relative to 1 mole of zinc chloride Add 1.2 moles of caustic soda while stirring, and react at 25° C. for 30 minutes. The pH of the reaction slurry was 5.91.

[0153] (rinse)

[0154] The obtained reaction slurry was washed with water.

[0155] (hydrothermal treatment)

[0156] The washed slurry was resuspended in ion-exchanged water, and hydrothermally treated at 120° C. for 15 hours.

[0157] (dry)

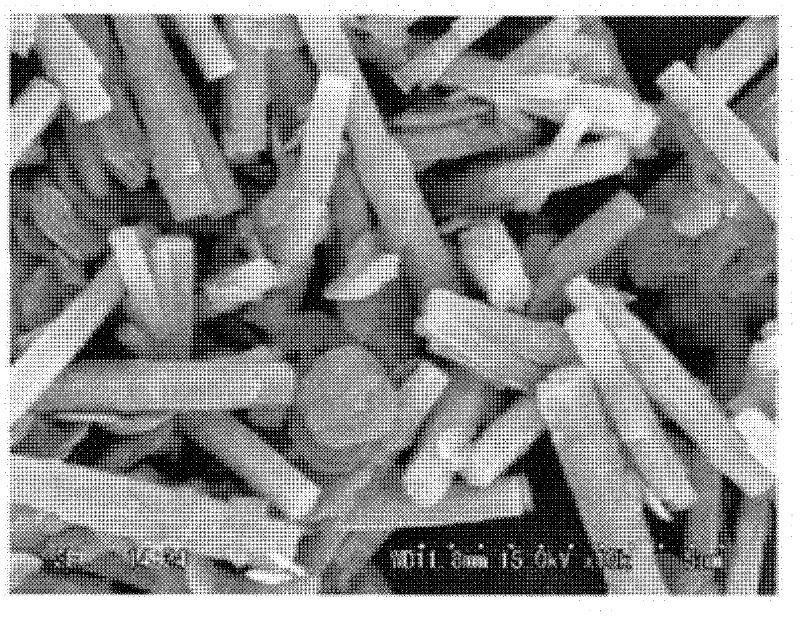

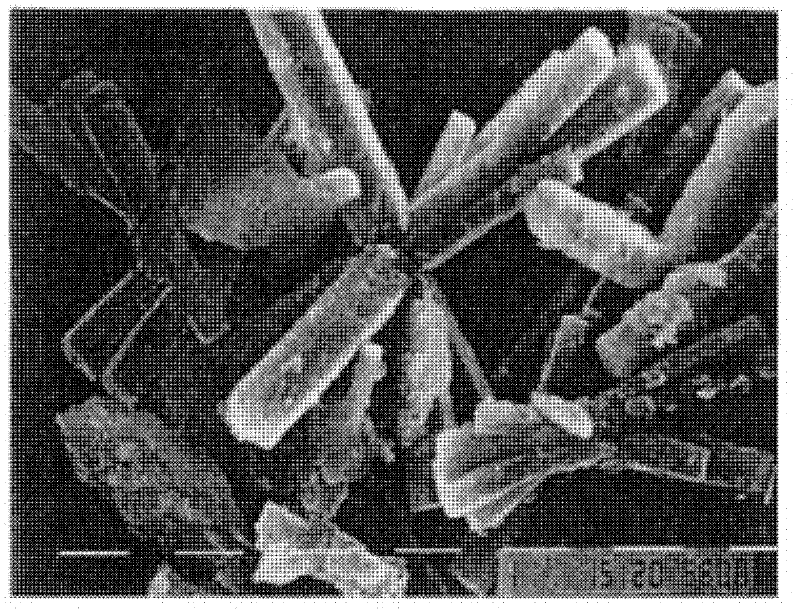

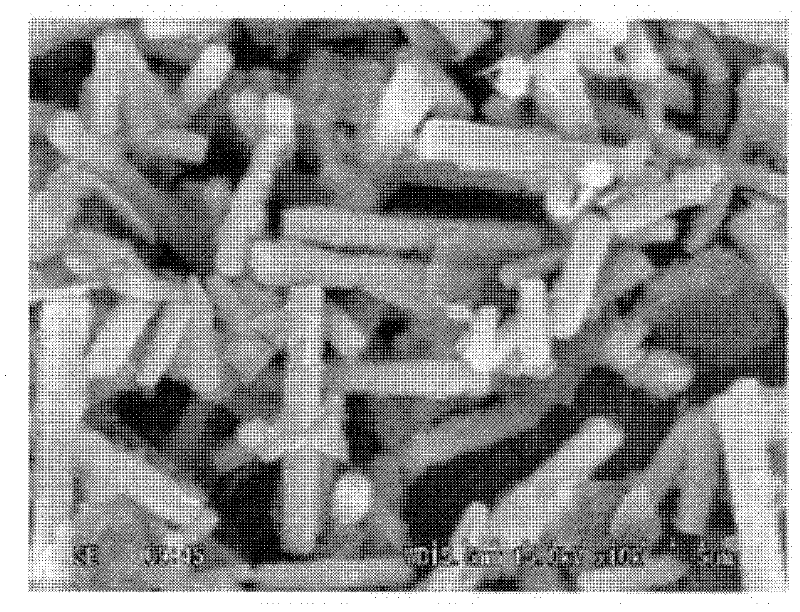

[0158] The obtained product was dehydrated, washed, and then dried to obtain particles. As a result of X-ray diffraction, the obtained particles were a mixture of zinc oxide and an alkaline zinc hydroxide compound, and it was found to be columnar crystals from the SEM photograph. Table 1 shows the ...

Synthetic example 2

[0160] Particles were obtained in the same manner as in Synthesis Example 1 except that the alkali equivalent ratio was changed to 1.4, the aluminum sulfate was changed to titanium(IV) sulfate, and the hydrothermal treatment conditions were changed to 170° C. and 20 hours. As a result of X-ray diffraction, the obtained particles were a mixture of zinc oxide and an alkaline zinc hydroxide compound, and it was found to be columnar crystals from the SEM photograph. Table 1 shows the properties of the particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com