Uniaxially coupled double-wind driven generator

A wind turbine, uniaxial technology, applied to wind turbine components, wind turbines, wind turbine combinations, etc., can solve the problems of inconvenience, large deflection force of the generator support frame, and inappropriate application of large generators, etc. Easy to use, high heat dissipation efficiency and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

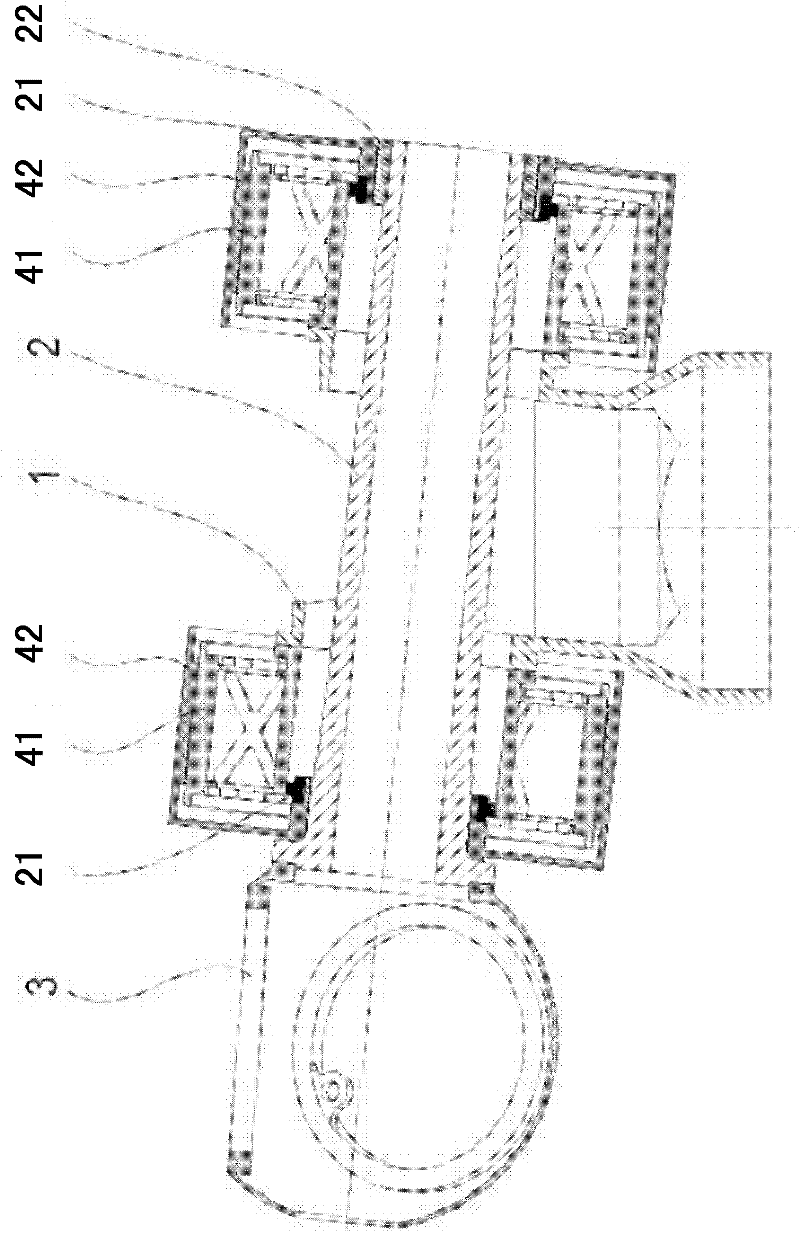

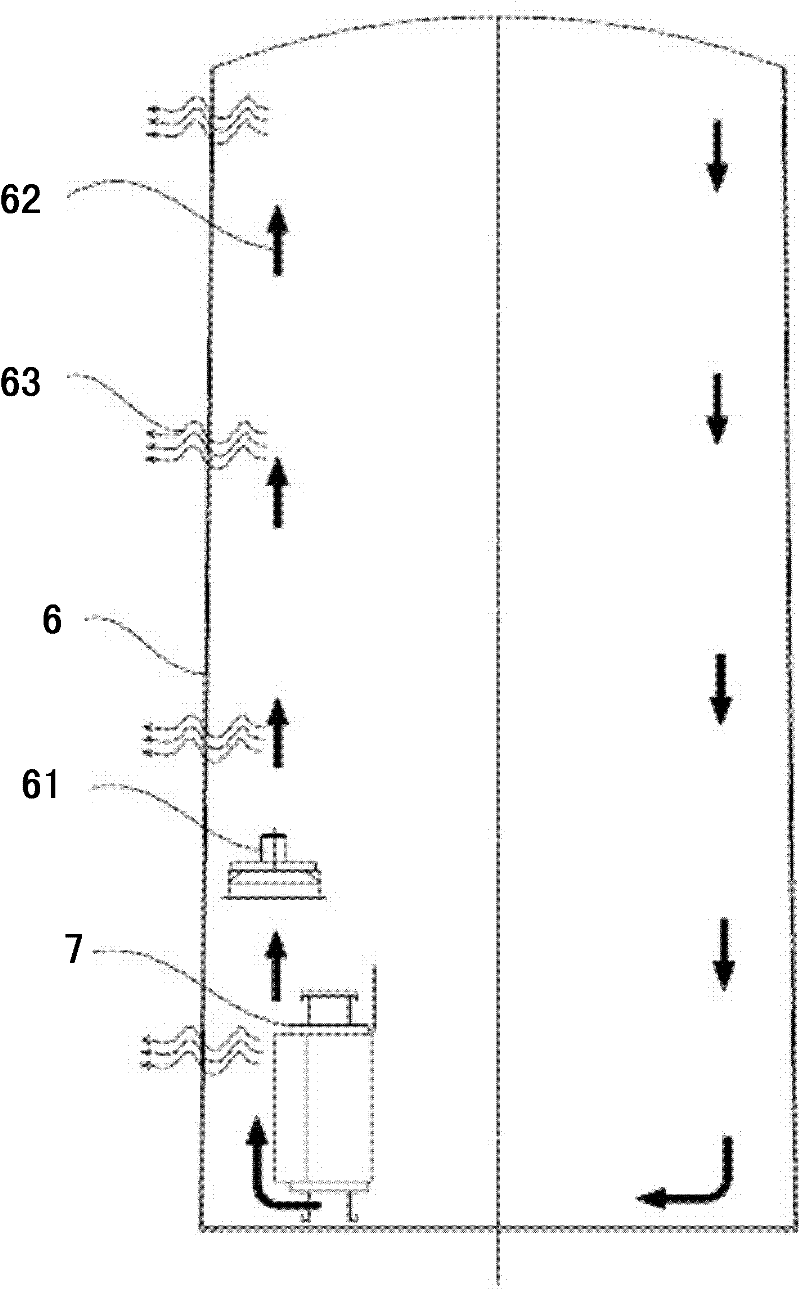

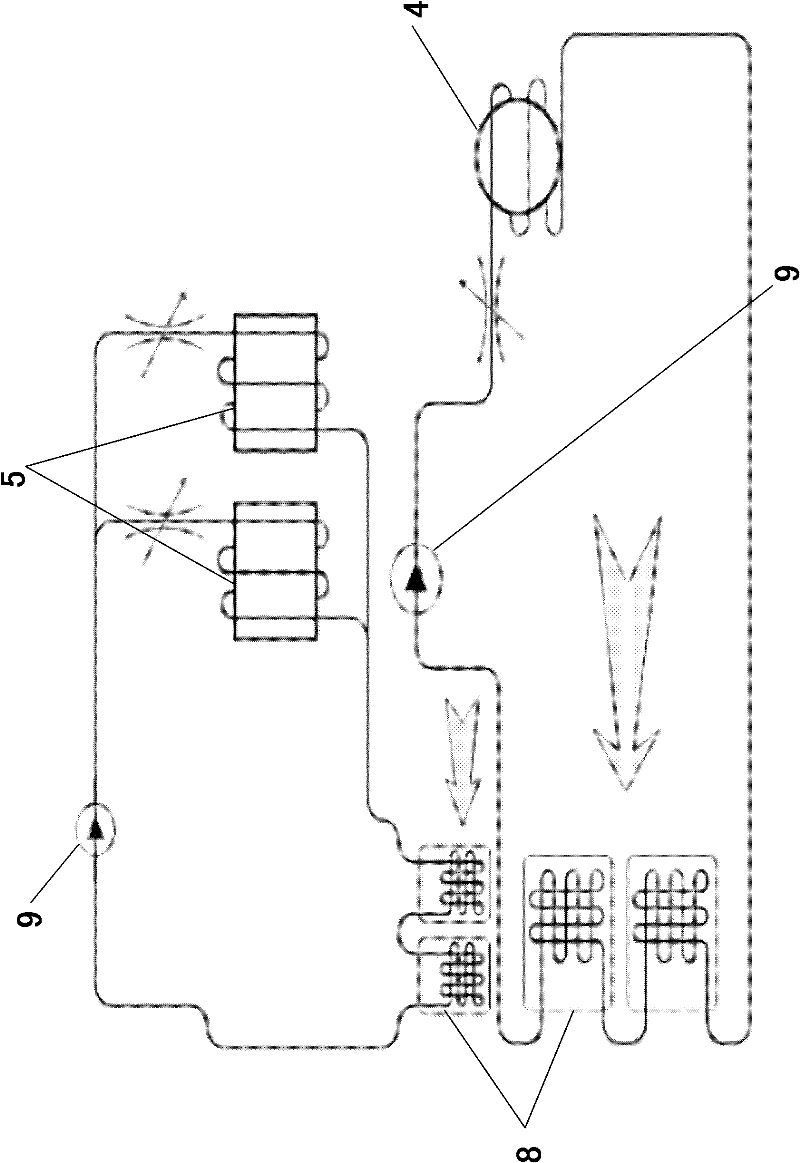

[0030] see figure 1 As shown, the single-shaft coupled dual wind power generator of the present invention mainly includes a tower 6 , a main frame 1 , a main shaft 2 , a hub 3 , a converter and two wind power generators 4 .

[0031] Among them, the two wind power generators 4 are medium voltage (MV) megawatt variable speed permanent magnet wind power generators, both of which are mainly composed of an inner stator 41 and an outer rotor 42 .

[0032] The stator 41 is preferably a coil winding made of rectangular copper conductors, forming multiple parallel circuits, using a three-phase system.

[0033] The rotor 42 is a permanent magnet, preferably a bipolar permanent magnet system. Each pole is connected by a plurality of magnetic steel blocks through clamps and interference rings. The outer surface of the magnetic steel blocks is provided with electroplating or epoxy anti-corrosion coating. A copper layer is provided between the anti-corrosion coatings of the magnetic steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com