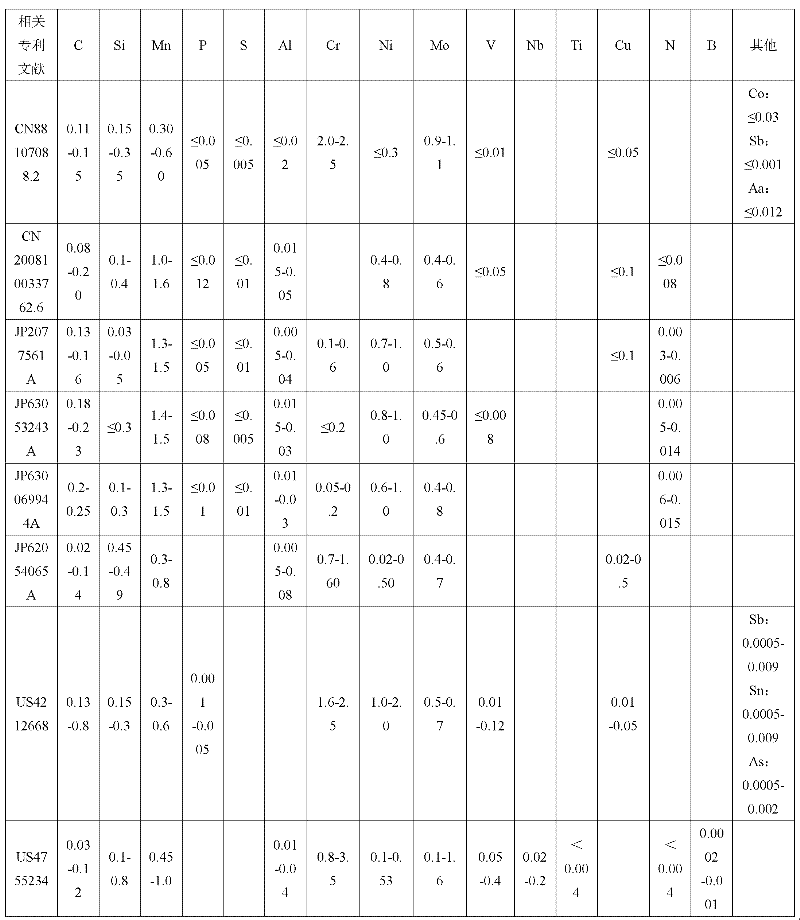

High-strength high-toughness nuclear power pressure vessel forging steel and its manufacturing method

A technology for a pressure vessel and a manufacturing method, applied in the field of steel for pressure vessels, can solve the problems of composition segregation, high Si content, excessive non-metallic inclusions, etc. The effect of excellent impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

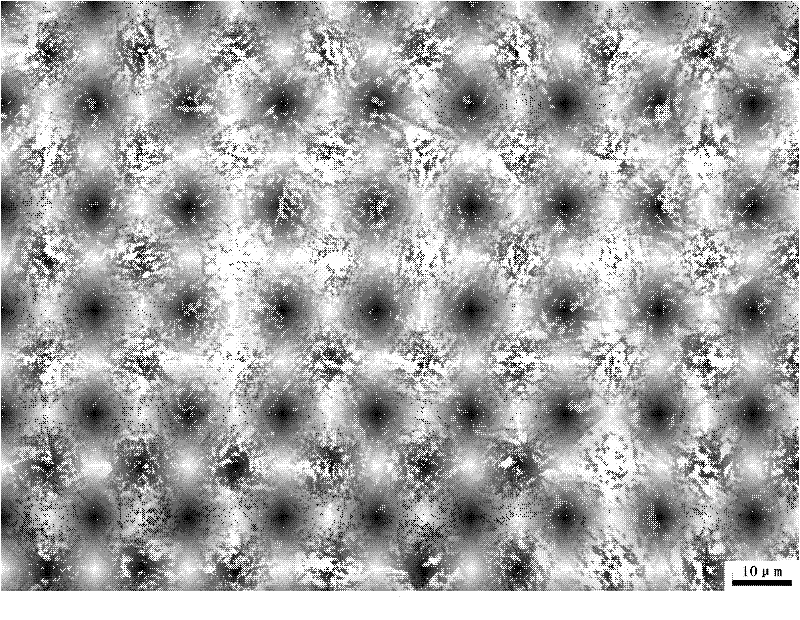

Image

Examples

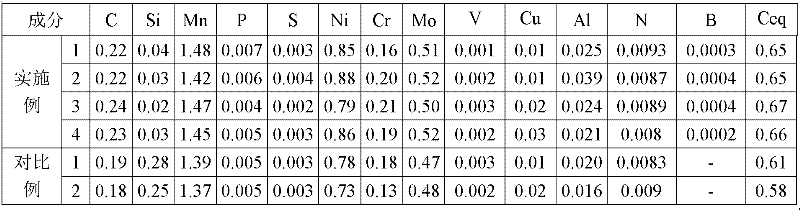

Embodiment 1

[0046] 50kg test steel smelted for vacuum induction melting furnace. Smelt and cast steel slabs according to the chemical composition shown in Table 1, heat the slabs to 1150°C, and carry out forging at a temperature above 950°C. The forging ratio is controlled at >3. After forging, the forgings were annealed at 650°C×8h, normalized and homogenized at 900°C×5h, and then air-cooled at 640°C×8h. Then, in the laboratory, a controllable speed heat treatment furnace was used to simulate the cooling rate of the 200mm thick industrial forging at the water-cooled 1 / 4T wall thickness. After 880°C×5h, it was cooled to 300°C at 36°C / min and then air-cooled at 640°C×8h. Tempering treatment, followed by simulated post-weld stress relief treatment, the heat treatment process is 610 ° C × 24h furnace cooling.

Embodiment 2

[0048] The implementation is the same as in Example 1, wherein the quenching temperature is 890°C, and the tempering temperature is 630°C. The laboratory controllable speed heat treatment furnace is used to simulate the cooling rate at the water-cooled 1 / 4T wall thickness of industrial forgings with a thickness of 180mm, and the simulated cooling rate is selected. 47°C / min.

Embodiment 3

[0050] The implementation is the same as in Example 1, wherein the quenching temperature is 870°C, and the tempering temperature is 645°C. The laboratory controllable speed heat treatment furnace is used to simulate the cooling rate at the water-cooled 1 / 4T wall thickness of industrial forgings with a thickness of 150 mm, and the simulated cooling rate is selected. 60°C / min. The simulated post-weld stress relief heat treatment process is 610℃×48h furnace cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com