Automatic counting machine for beverage bottle caps

A counting machine and bottle cap technology, which is applied to counting mechanisms/items, counting objects, counting items shipped through a conveying device, etc., can solve the problems of high labor intensity, complex structure, time-consuming and laborious counting, etc., and achieve a wide range of applications. , the effect of high counting efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

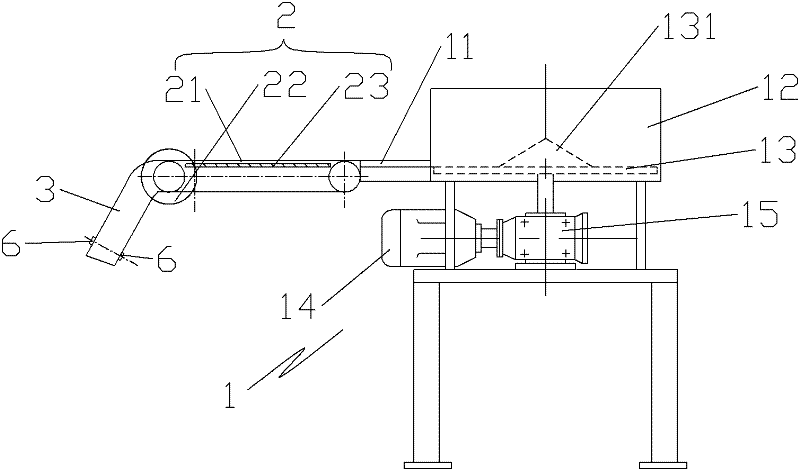

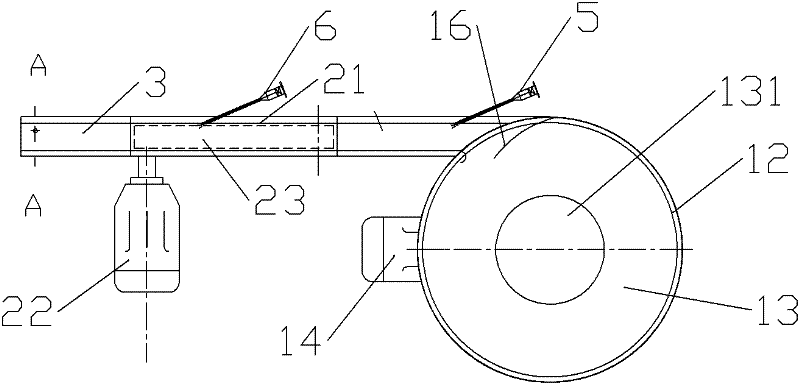

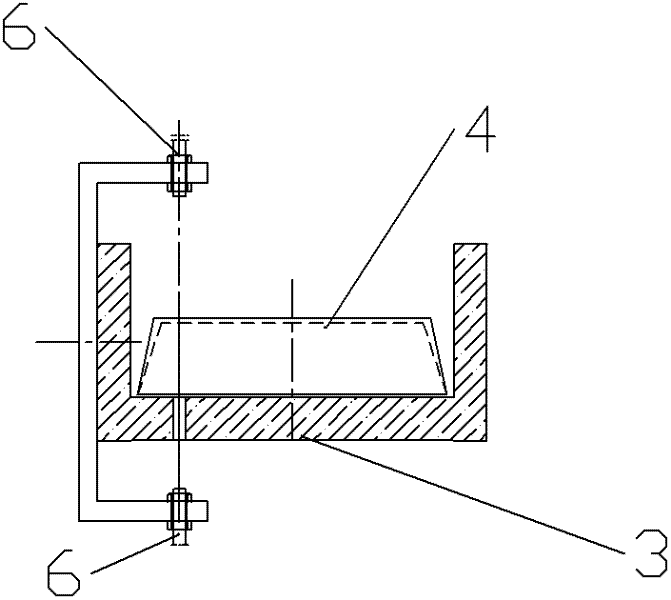

[0020] Such as Figures 1 to 3 As shown, an automatic counting machine for beverage bottle caps according to the present invention includes a bottle cap feeding device 1 provided with a feeding track 11, and the outlet of the feeding track 11 is provided with a magnetic suction separation conveying device for separating and conveying a single bottle cap. Device 2, the outlet of the magnetic separation conveying device 2 is connected with a curved downward blanking track 3, and a counter is arranged on the blanking track.

[0021] Further, the above-mentioned magnetic separation conveying device 2 includes a conveying belt 21 , a conveying belt driving motor 22 , a conveying belt driving wheel, a conveying belt driven wheel and a magnetic track 23 arranged under the working belt of the conveying belt 21 . When the bottle cap 4 passes through the magnetic track 23, because it is made of iron, it is magnetically attracted on the conveyor belt 21 of the magnetic track, because the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com