Depositing and use separation station for a sheet punching press

A partially separated and useful technology, applied in the direction of transportation and packaging, container manufacturing machinery, carton/carton manufacturing machinery, etc., can solve problems such as production loss, and achieve the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

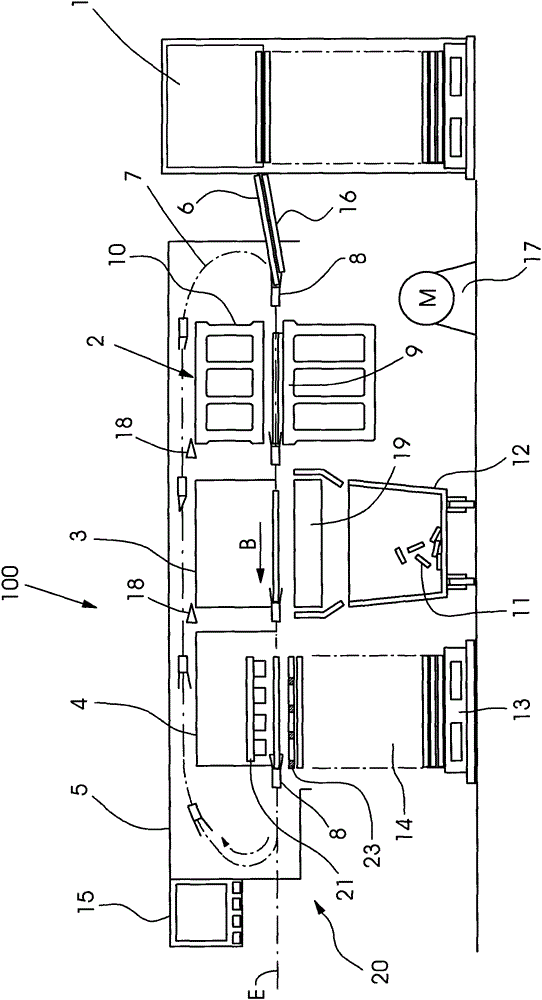

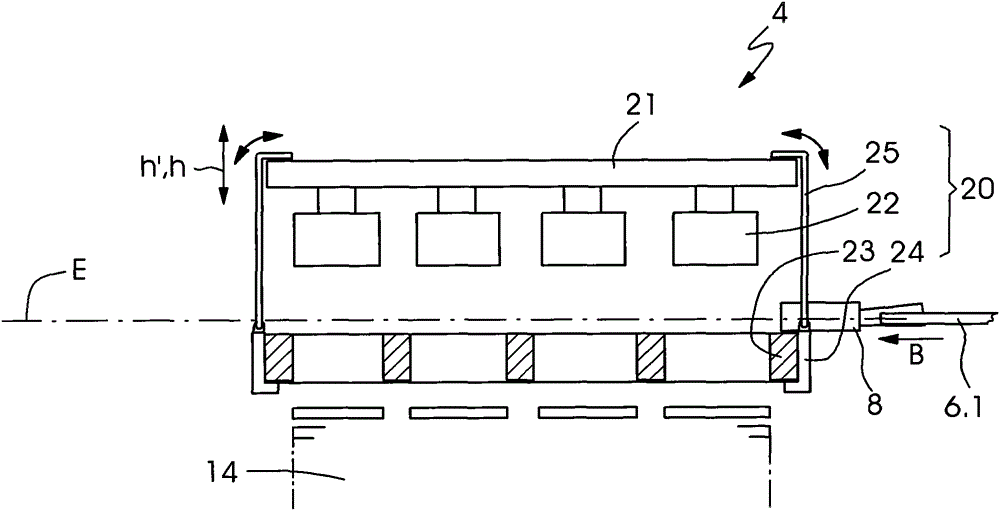

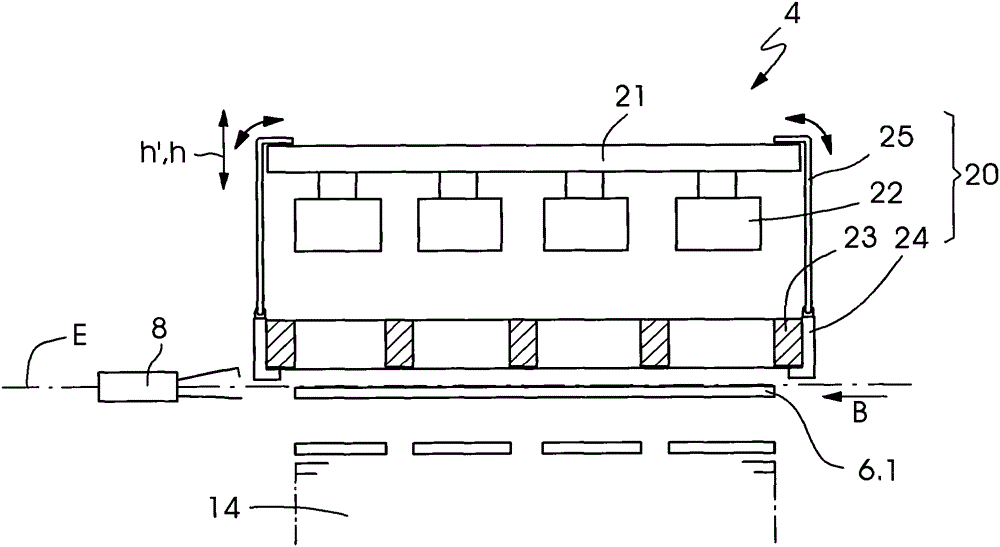

[0038] figure 1 The schematic design of a sheet die-cutting and embossing machine 100 for die-cutting, stripping and placing sheets made of paper, cardboard and the like is shown in FIG. The die-cutting and embossing machine 100 has a feeder 1, a die-cutting station 2, a stripping station 3 and a delivery 4 with a laying and useful part separation station 20, which consist of a common machine housing 5 carrying and surrounding. The processing stations 2 , 3 , 4 are accessible from one side, the so-called operator side; the drive train of the sheet-cutting and embossing machine 100 is located on the opposite side, the so-called drive side.

[0039] Sheets 6 are separated from a stack by a feeder 1 , fed to the sheet transport system 7 and gripped by grippers fixed to the gripper bridge of the gripper carriage 8 and moved along the The sheet transport direction B is intermittently drawn through the various stations 2 , 3 and 4 of the die-cutting and embossing machine 100 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com