Large-size shallow-drawing stamping part progressive die

A large-scale, progressive die technology, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as low production efficiency, and achieve the effect of ensuring processing accuracy, reducing production costs, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

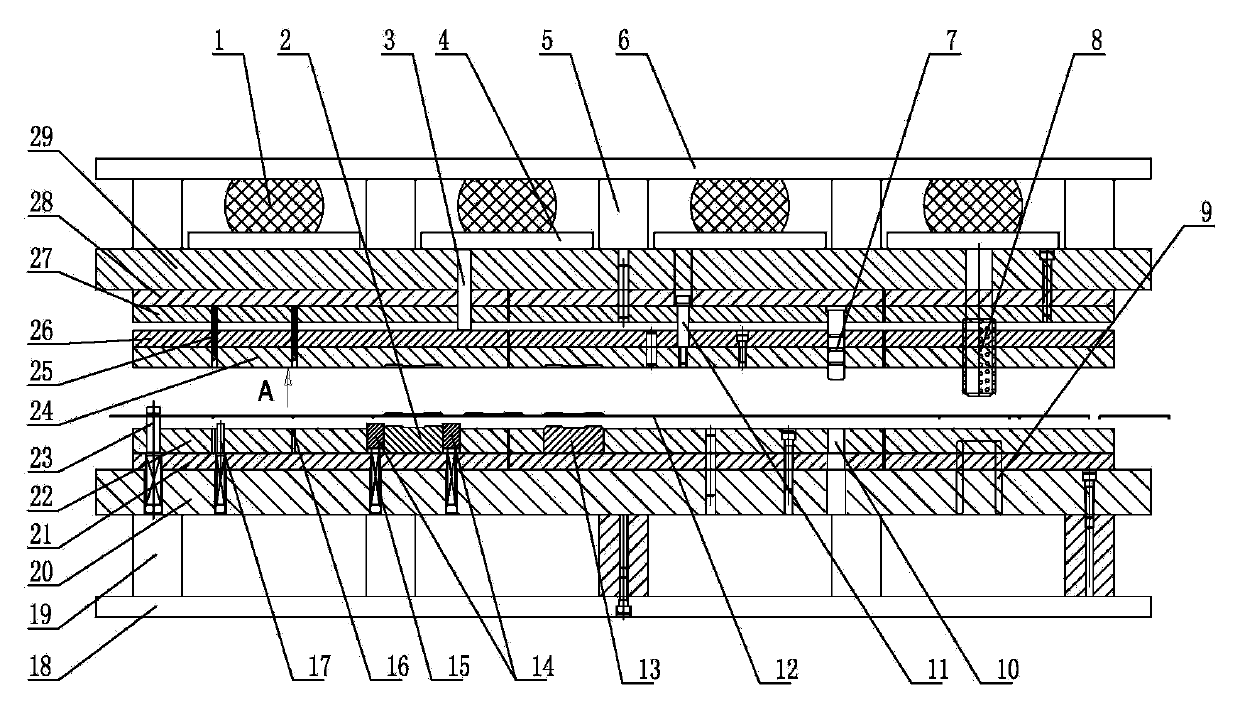

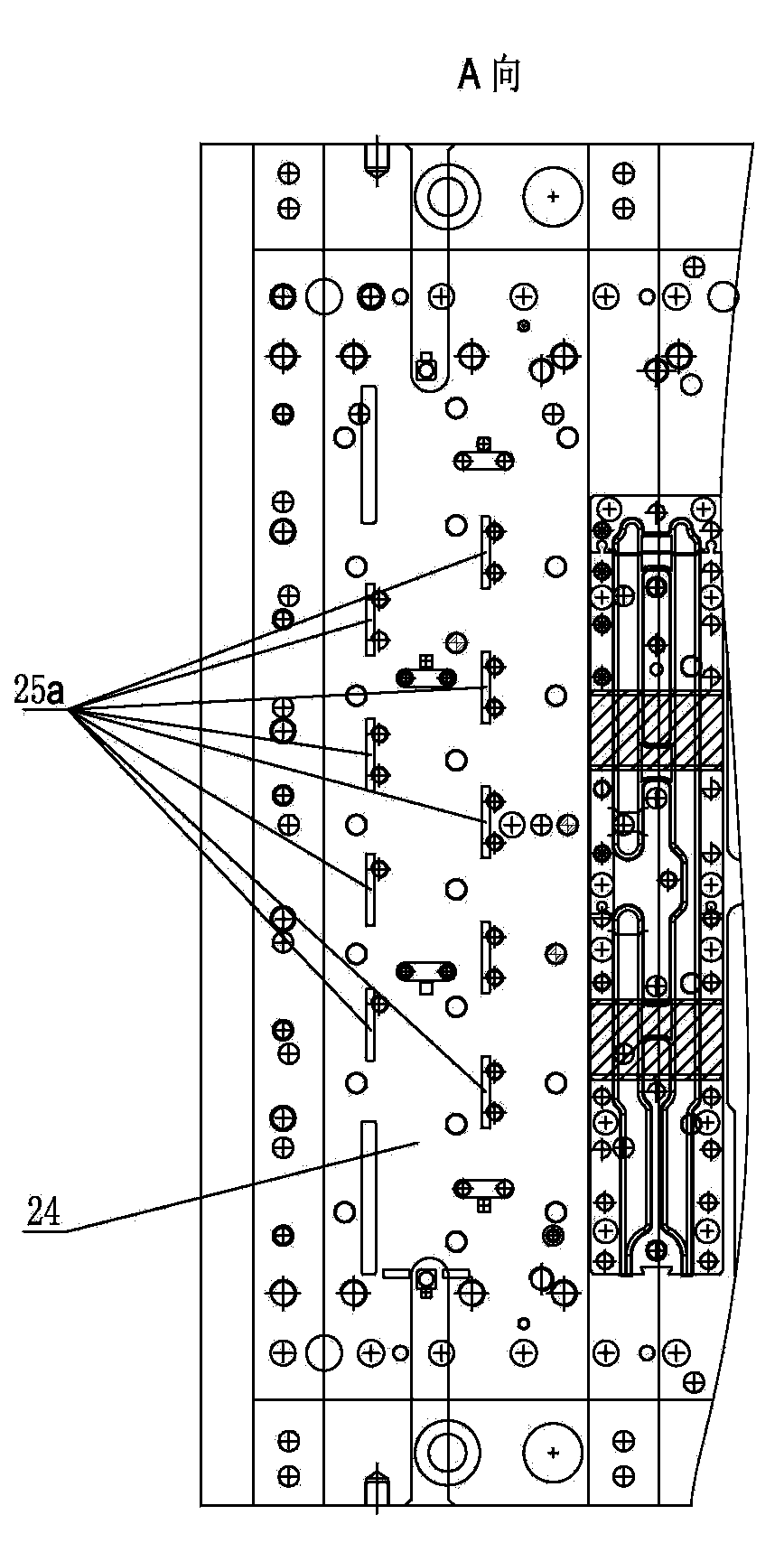

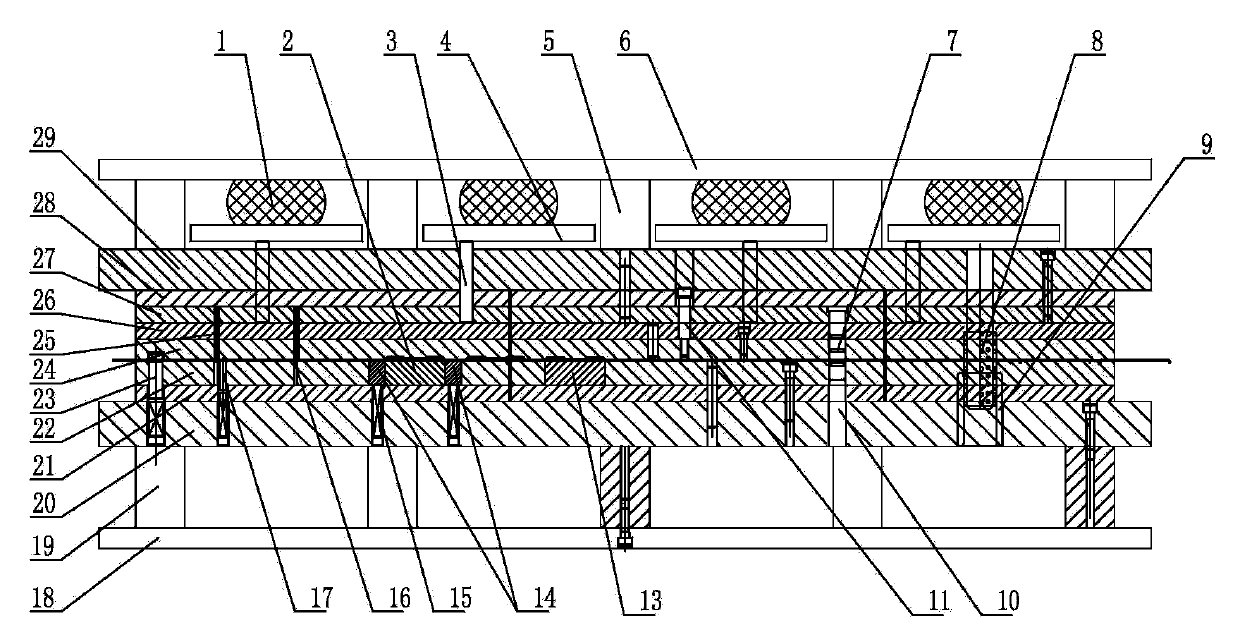

[0018] Such as figure 1 and 2 As shown, it is a progressive die for large-scale shallow deep-drawing sheet metal parts, including correspondingly arranged upper dies and lower dies; Supporting plate 6, punching plate 4 is provided on the upper surface of upper die base 29, and polyurethane spring 1 is arranged between knocking plate 4 and upper supporting plate 6, and upper backing plate 28 is provided on the lower side of upper die base 29, and upper backing plate 28 lower sides are connected with upper clamping plate 27, and upper clamping plate 27 below is connected with stop plate 26 through the contour screw 11 that can move up and down, and stop plate 26 lower sides are fixedly connected with stripper plate 24; There is a knockout rod 3, the upper end of the knockout rod 3 is in contact with the lower side of the knockout plate 4, and the lower end of the knockout rod 3 is in contact with the upper side of the stop plate 26; The lower backing plate 18 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com