Large cylinder turning and boring combined processing method and device

A large-scale cylinder, combined processing technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of long time-consuming, difficult precision control, inability to meet the processing accuracy, etc., to achieve high processing accuracy, processing equipment Assemble simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

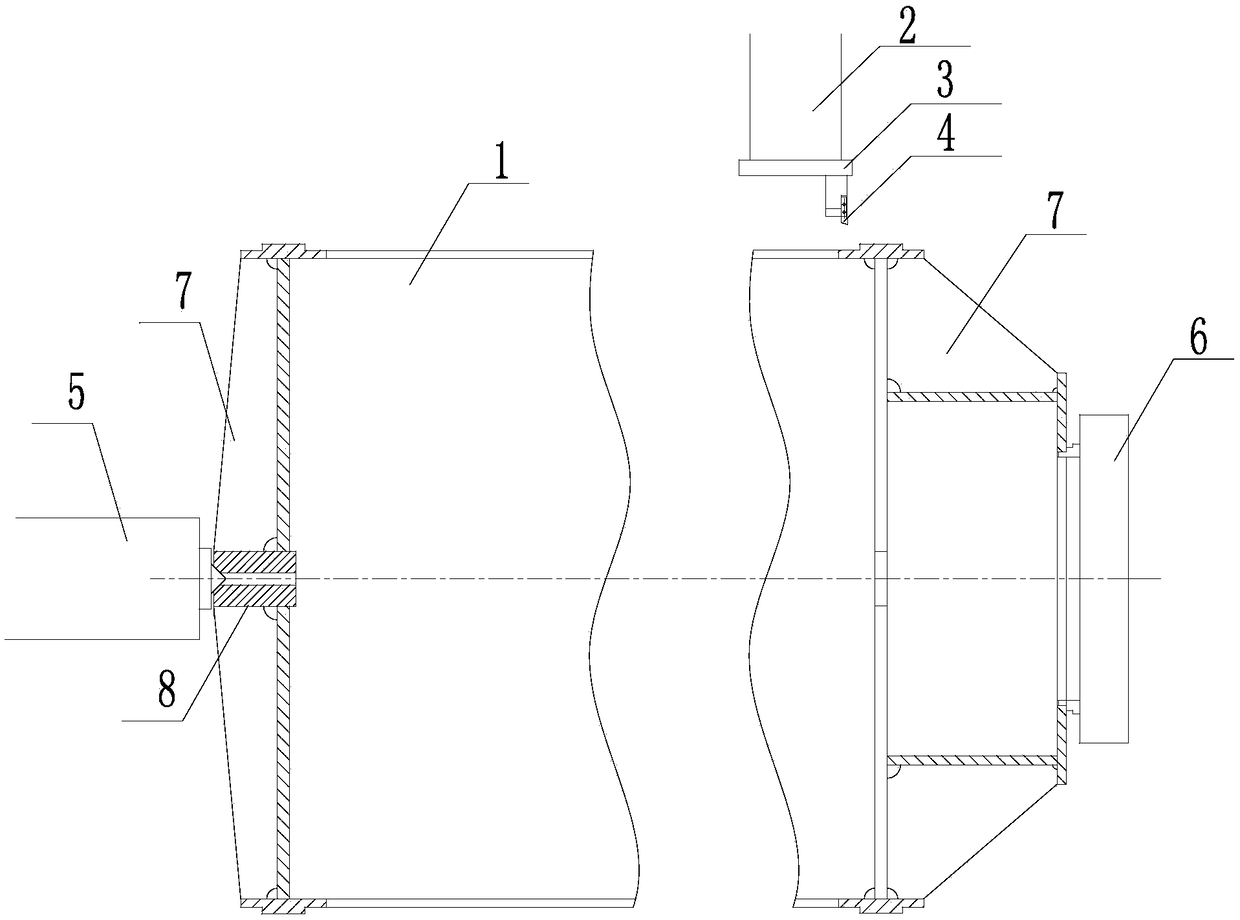

[0024] The following processing of the cement mill cylinder is taken as an example to further illustrate the present invention.

[0025] The cement mill cylinder is a welded structural part, with a maximum outer diameter of φ4665mm, a total length of 16330mm, and a total weight of 108 tons of finished products.

[0026] Its processing requirements are as follows

[0027] 1) The cylinder body 1 must be processed as a whole after welding;

[0028] 2) Ensure that the coaxiality deviation of the φ4390 outer circle at both ends of the total length (the contact part with the sliding bearing seat) is less than 0.2mm, and the surface roughness is less than a0.8;

[0029] 3) The outer circle of the φ4665 flange and the two ends (where the large ring gear is installed) and the axis of the outer circle of φ4390 are coaxial and vertical, and the error is less than 0.5mm.

[0030] The processing steps are as follows:

[0031] a. Preparation before processing

[0032] a 1 When the cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com