Preparation method of carbon nanotube field emission cathode

A field emission cathode and carbon nanotube technology, which is applied in cold cathode manufacturing, discharge tube/lamp manufacturing, electrode system manufacturing, etc., can solve problems such as difficulty in controlling the length and density of carbon nanotubes, easy lodging of carbon nanotubes, etc. Achieve the effect of improving the field emission characteristics, reducing the shielding effect, and improving the aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

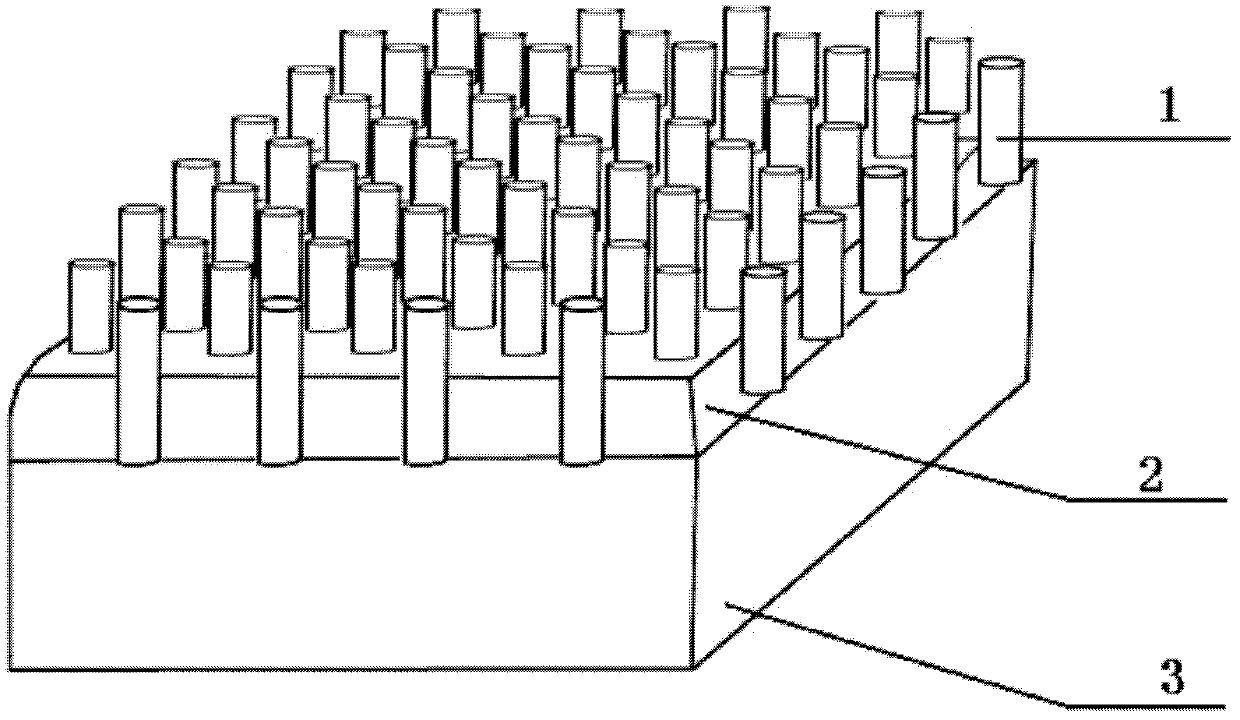

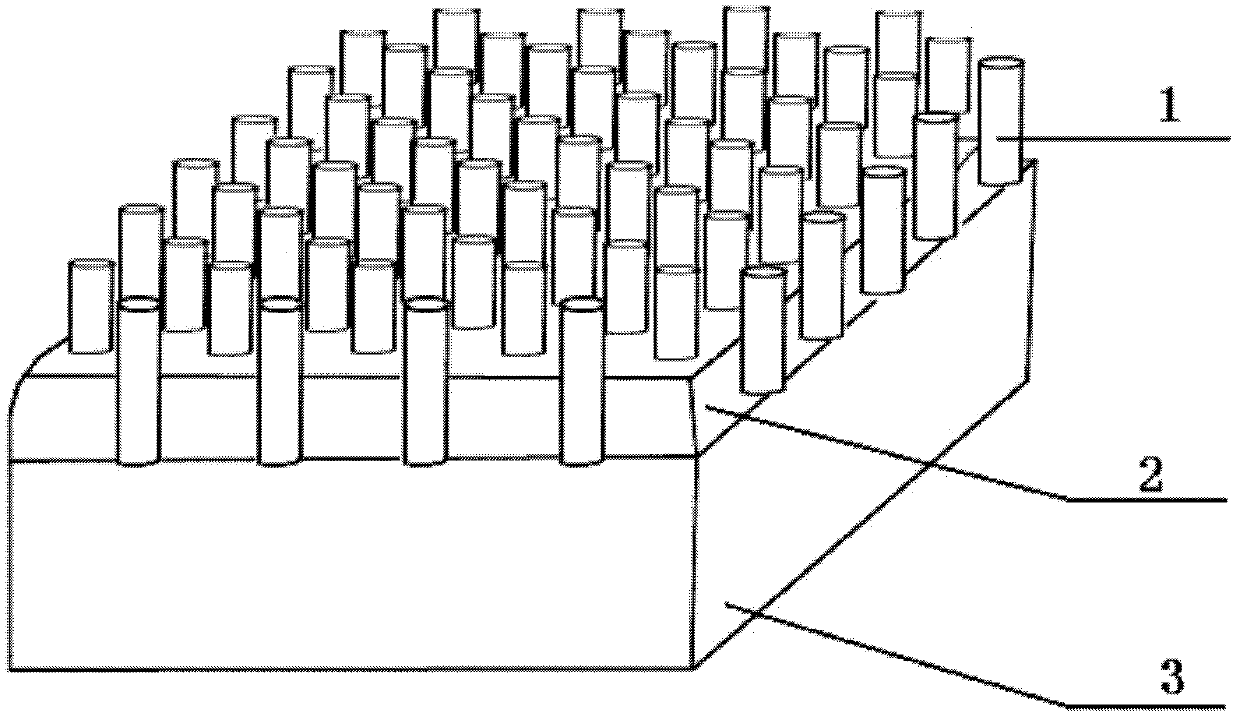

[0023] Such as figure 1 The preparation method of the shown carbon nanotube field emission cathode, the preparation method steps are as follows:

[0024] Step 1. The porous anodized aluminum template is prepared by the secondary anodic oxidation method, and the decompression method is used in the later stage of preparing the porous anodized aluminum template to reduce the hole diameter at the bottom of the porous anodized aluminum template; the specific process is as follows:

[0025] Ultrasonic cleaning of high-purity aluminum sheets (99.9999% pure) with a diameter of 1-2 cm and a thickness of 1-2 mm in 1M NaOH solution for 3-5 minutes, after polishing, at room temperature, voltage 40V, 0.3M oxalic acid solution Carry out anodic oxidation for the first time in 2 hours to obtain A; corrode A with a mixed solution of 6%wt phosphoric acid and 1.8%wt chromic acid at a constant temperature of 30°C for half an hour to remove the oxide film on the surface of A , for the second anod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com