Spittle alcoholicity test strip and production method thereof

A production method and technology of test strips, which are applied in the field of biosensors, can solve the problems of limited storage conditions and storage time of test strips, inability to effectively balance enzyme activity and stability, and long-term storage of enzymatic reaction reagents, etc. Oxidation rate, simple structure, good effect of maintaining enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

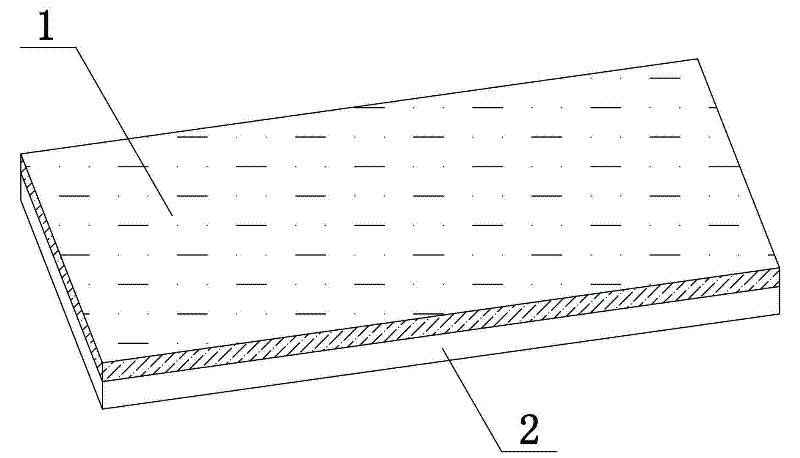

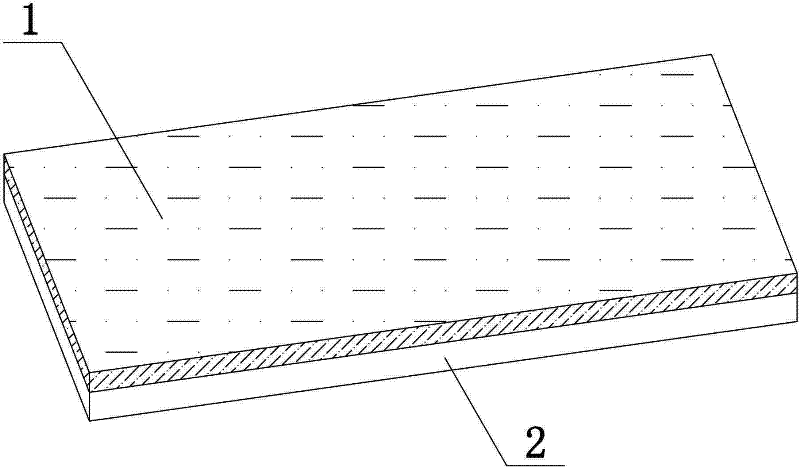

[0025] Such as figure 1 Shown, a kind of saliva alcohol content test strip, it comprises substrate 2 and the reaction test strip 1 that is pasted on described substrate 2 one side surface, and described reaction test strip 1 is to dip into developer solution and double enzyme reaction liquid successively dry filter paper; the substrate 2 is any one of polyvinyl chloride, polycarbonate, polystyrene.

[0026] A kind of preparation method of saliva alcohol content test strip, this preparation method comprises the following steps:

[0027] Step 1. First cut the thick filter paper into 0.4-0.6cm wide filter paper, then completely immerse the filter paper in the developer solution, keep it for 5-10 seconds, take it out, and keep it at 25°C-35°C, away from light, under vacuum Dry for 15-25 minutes to obtain color filter paper, and store it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com