Truss imitating type damper structure transfer layer

A technology for structural transfer floors and dampers, which is applied to building components, earthquake resistance, etc., can solve problems such as insufficient earthquake resistance, achieve simple construction, reduce bending moment and shear force, and reduce interstory displacement and interstory shear force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

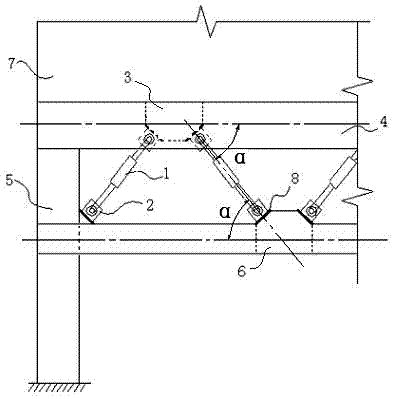

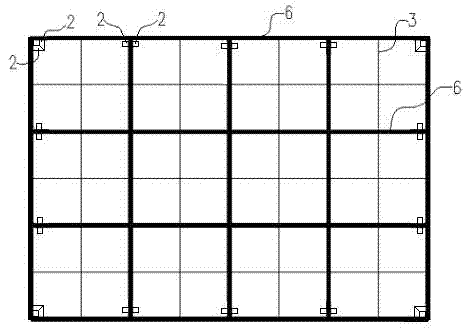

Embodiment 1

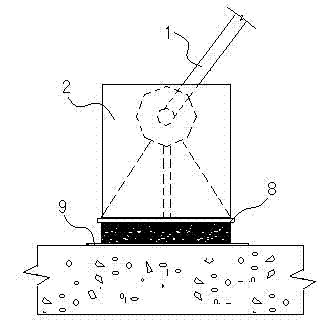

[0023] Example 1: The transfer layer of the truss-like damper structure is composed of the frame column 5 of the two main facades, the transfer beam 4, the floor beam 6 and the damper 1 to form the transfer layer of the truss-like damper structure; the transfer beam 4 supports the seismic wall 7 The upper building structure, the transfer beam 4 and the floor beam 6 are provided with corresponding secondary beams 3; the support 2 is installed under the secondary beam 3 of the beam system surrounding the beam system close to the transfer beam 4, and the beam of the floor beam 6 The support 2 is also installed on the beam system of the floor beam 6, and the support 2 above the beam system of the floor beam 6 is installed on the secondary beam 3 or the floor beam 6 to ensure that when the damper 1 is installed on the support 2 above the beam system of the floor beam 6 It corresponds to the lower support 2 of the secondary beam 3 of the beam system of the conversion beam 4 . The ...

Embodiment 2

[0024] Example 2: The structure of the truss-type transfer layer imitating the truss-type damper structure, the structure of the truss-type transfer layer formed by the frame column 5, the transfer beam 4, the floor beam 6 and the damper 1 is the same as that of the first embodiment. Backing plate 9 adopts 20mm cast steel plate. Damper 1 adopts hydraulic damper. Soft base pad 8 adopts plastic pad. The installation angle α between the central axis of the damper 1 and the horizontal center line of the transfer beam 4 or the floor beam 6 is 55°.

[0025] The invention is mainly used for the seismic design research, conceptual design and actual engineering design of the structure with the transfer layer in the building, and is mainly composed of a viscoelastic damper and a laminated rubber bearing, wherein: the viscoelastic damper is in the beam system of the transfer beam In the range of the two main facades, the transfer beams on the four sides of the structure are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com