White contrail production agent for flight performance

A smoke agent, white smoke technology, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of unsuitable long-term use, reduced economic benefits, defects in the effect of pulling smoke, etc., to achieve large economic benefits, strong cost advantages, and guarantee flight training. and the effect of air show missions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

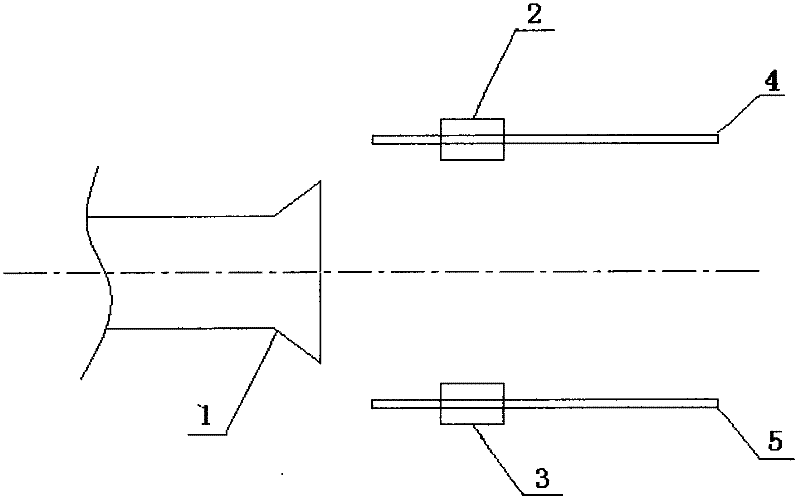

Image

Examples

Embodiment 1

[0038] The composition of the white smoke pulling agent includes: basic components, modified components, rubber core, antioxidants, antirust agents, and antifoaming agents:

[0039] The basic component has a distillation range of 286°C to 338°C and a density of 842.5kg / m 3 , 20 ℃ kinematic viscosity 8.2125mm 2 / s, mineral oil with a flash point of 228°C,

[0040] The modified component has a distillation range of 370°C to 380°C and a density of 0.8558kg / m 3 、20℃ kinematic viscosity is 21.3642mm 2 / s, mineral oil with a flash point of 288°C. The added weight ratio of the modified component is 15% of the base component weight;

[0041] The rubber core is a mixture of hydrated iron oxide, hydrated aluminum oxide and hydrated barium oxide, and the added weight ratio is 0.1% of the weight of the base component;

[0042] The antioxidant is didodecyl diphenylamine, and the added weight ratio is 0.5% of the base component weight;

[0043] The antirust agent is ditridecyl phospha...

Embodiment 2

[0046] The composition of the white smoke pulling agent includes: basic components, modified components, rubber core, antioxidants, antirust agents, and antifoaming agents:

[0047] The basic component has a distillation range of 286°C to 338°C and a density of 842.5kg / m 3 、20℃ kinematic viscosity is 8.2125mm 2 / s, mineral oil with a flash point of 228°C,

[0048] The modified component has a distillation range of 370°C to 380°C and a density of 0.8558kg / m 3 、20℃ kinematic viscosity is 21.3642mm 2 / s, mineral oil with a flash point of 288°C, the weight ratio of the modified component added is 10% of the base component weight;

[0049] The rubber core is a mixture of hydrated calcium oxide, hydrated titanium dioxide, and preferably hydrated iron oxide, and the added weight ratio is 2% of the base component weight;

[0050] The antioxidant is selected from 2,6-di-tert-butyl-p-cresol. The added weight ratio is 5% of the base component weight;

[0051] The antirust agent is ...

Embodiment 3

[0054] The composition of the white smoke pulling agent includes: basic components, modified components, rubber core, antioxidants, antirust agents, and antifoaming agents:

[0055] The basic component is a distillation range of 250°C to 350°C and a density of 841.9kg / m 3 、20℃ kinematic viscosity is 6.3544mm 2 / s, mineral oil with a flash point of 149°C;

[0056] The modified component has a distillation range of 360°C to 420°C and a density of 0.8599kg / m 3 、20℃ kinematic viscosity is 28.366mm 2 / s, a mineral oil with a flash point of 282°C; the weight ratio of the modified component added is 22.5% of the base component weight;

[0057] The glue core is hydrated calcium oxide, and the weight ratio added is 3% of the base component weight;

[0058] The antioxidant is selected from 2,6-di-tert-butyl-p-cresol, and the added weight ratio is 2.5% of the base component weight;

[0059] The antirust agent is zinc dinonylnaphthalene sulfonate, and the added weight ratio is 1.5% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com