Fixed-point quantitative automatic loading method of bulk sulfur

A sulfur and automatic positioning technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems that dust has a great impact on the health of production personnel, the impact of the weather on loading operations, and the degree of automation is not high, so as to achieve efficient dust removal and dust suppression Measures, improve the safety of operation, the effect of fast turnover of wagons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

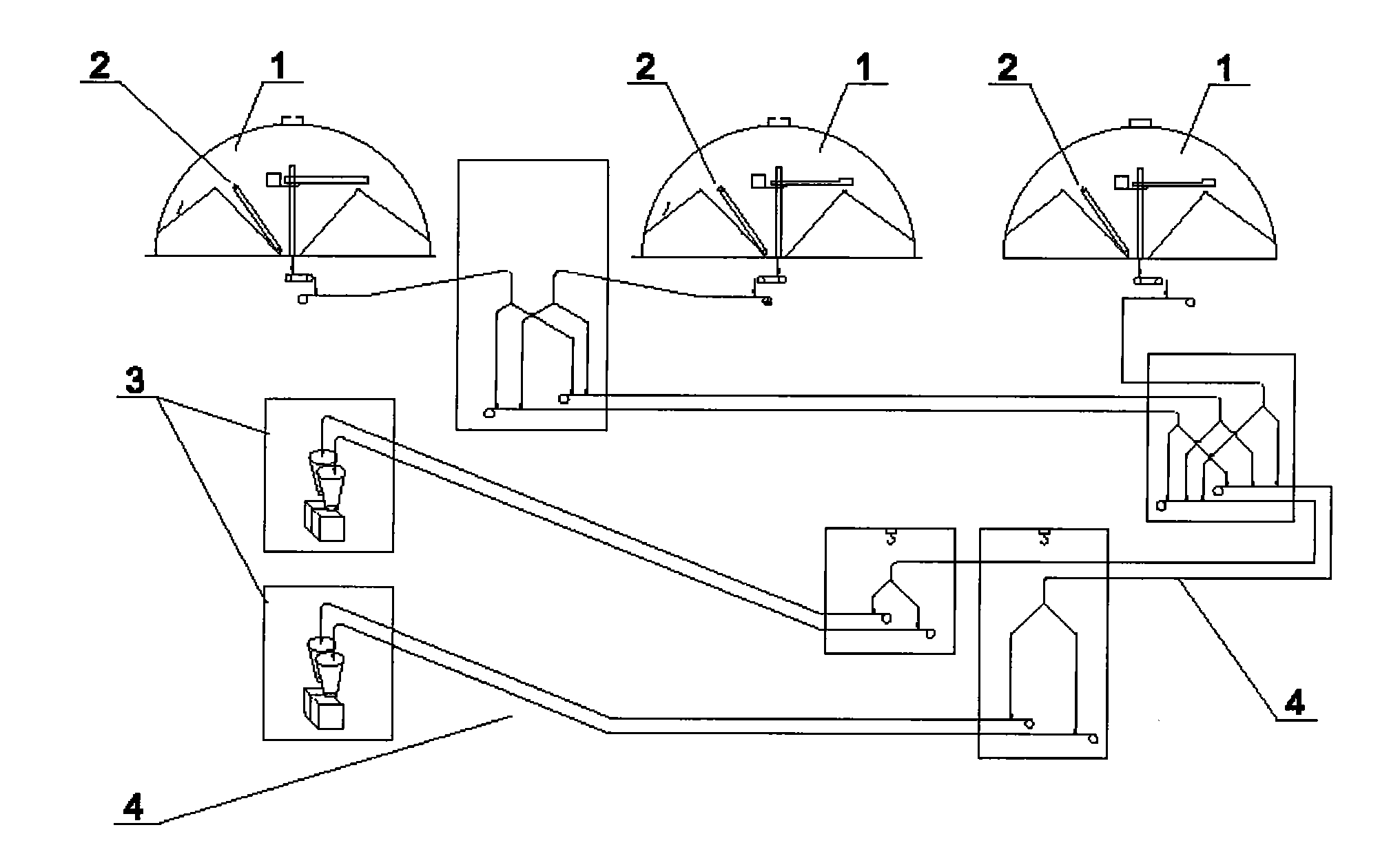

[0061] The annual sulfur output of a natural gas purification plant is about 3 million tons, and the daily output is about 8,640 tons. How to store such a large sulfur output, load it into trucks and transport it abroad to ensure the coordinated operation of all links in sulfur production and sales is a key problem that needs to be solved.

[0062] If the bag loading method is adopted, no matter whether it is loading from the sulfur warehouse or directly loading from the sulfur forming automatic packaging and palletizing, it is calculated that each person carries one bag per minute, and about 250 on-site handling personnel are required per shift, and The porters are labor-intensive. This method not only cannot guarantee the loading accuracy, but also needs to be reversed many times at the same time, the loading speed is slow, the loading efficiency is low, and it cannot meet the needs of large-scale production; a large number of moving personnel poses hidden dangers to the safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com