pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of reduced handling stability, reduced lateral rigidity, reduced noise performance, etc. Rigidity, high drainage, and the effect of improving noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described in detail.

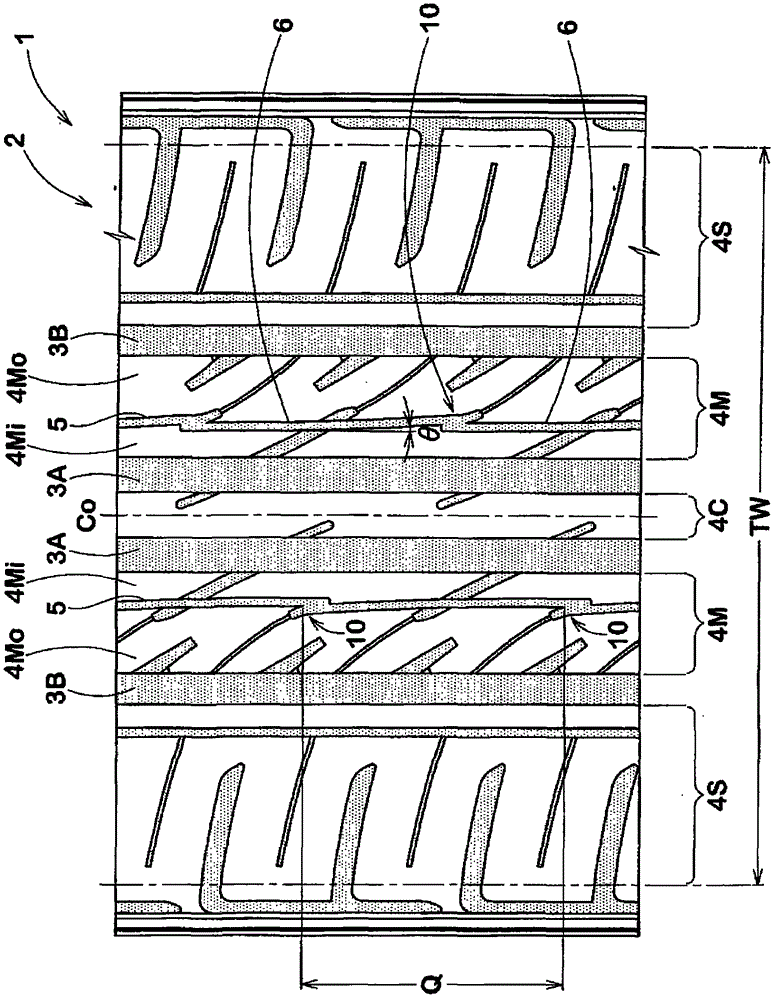

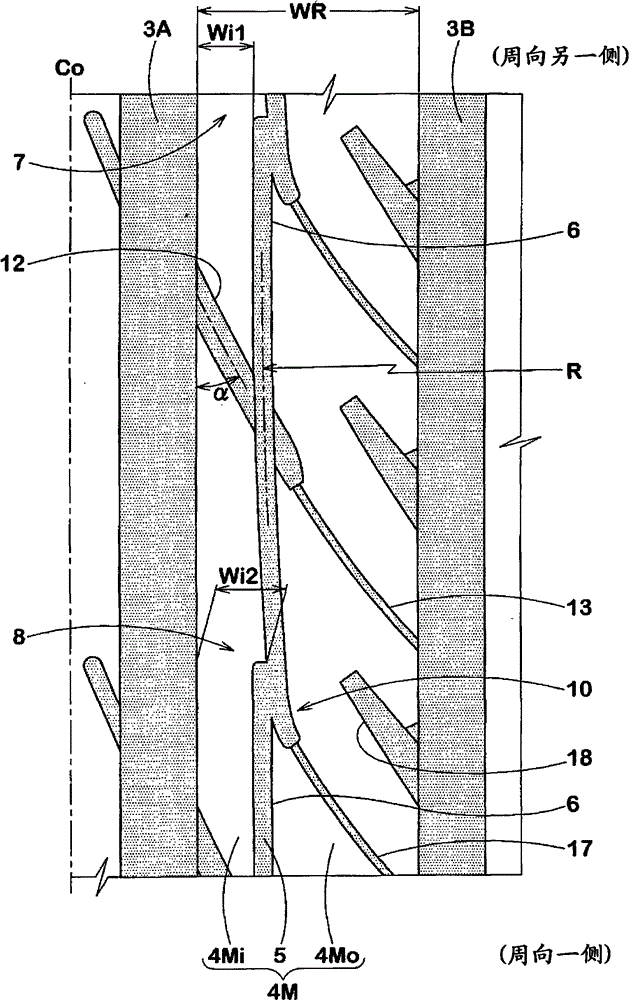

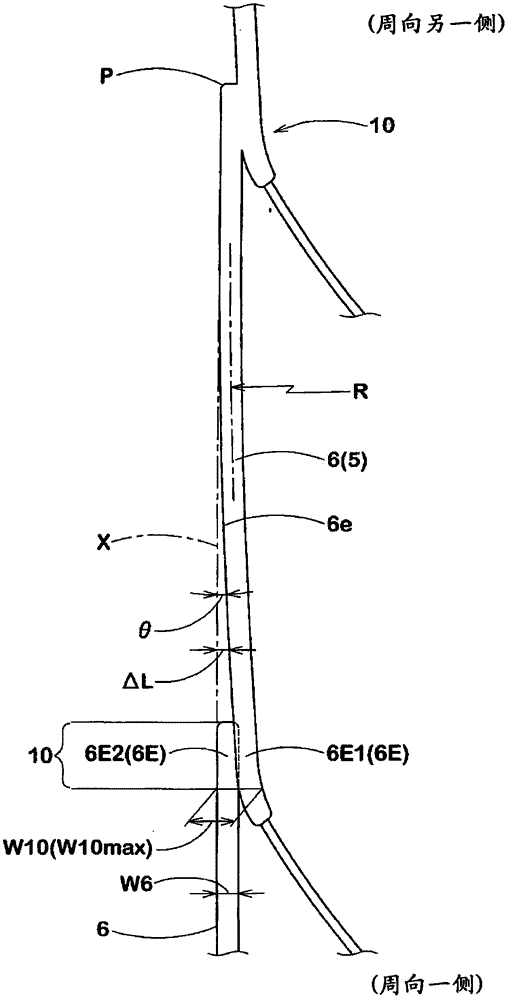

[0031] like figure 1 As shown, the pneumatic tire 1 of this embodiment has, on the tread portion 2 , a pair of inner circumferential main grooves 3A extending on both sides of the tire equatorial plane Co, and a pair of outer circumferential main grooves 3B arranged on both outer sides of the inner circumferential main grooves 3A. , thus the tread portion 2 is divided into the following five ribs, namely: the central rib 4C between the inner circumferential main grooves 3A, 3A, the middle rib between the inner circumferential main groove 3A and the outer circumferential main groove 3B 4M, 4M, and shoulder ribs 4S, 4S on the outer side in the tire axial direction than the outer circumferential main groove 3B.

[0032] Here, as the above-mentioned inner circumferential main groove 3A, one circumferential main groove extending on the tire equatorial plane Co may be used. In this case, the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com