Easy-to-peel cover film

An easy-to-tear and easy-to-peel technology, which is applied in the direction of closing, packaging, and layered products, can solve the problems of uneven back cover film, poor anti-pollution heat sealing effect of heat-sealing layer materials, and poor sensory perception of product packaging. Achieve the effects of improved stress crack resistance, excellent anti-pollution heat sealing performance, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

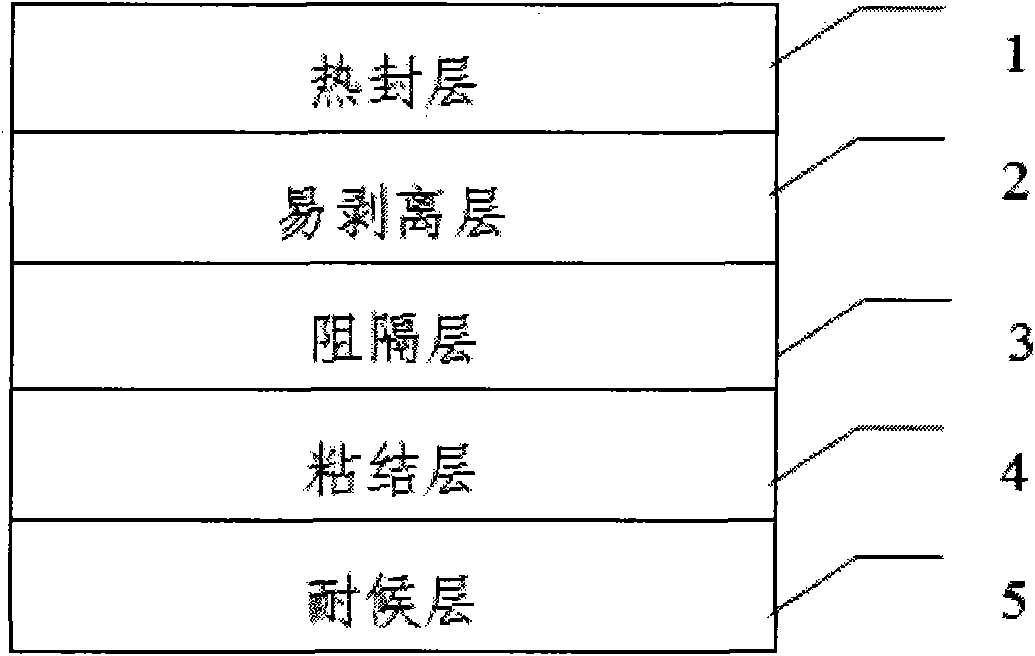

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] see figure 1 As shown, a new type of easy-peeling cover film, which includes a five-layer structure of heat-sealing layer 1, easy-peeling layer 2, barrier layer 3, adhesive layer 4 and weather-resistant layer 5 arranged in sequence.

[0024] Further, the addition amount of the low-density polyethylene and metallocene low-density polyethylene in the heat-sealing layer 1 multi-layer co-extruded ethylene-vinyl acetate co-extruded film layer accounts for 30% to 40% of the total weight.

[0025] Further, the low-density polyethylene in the easy-peelable layer 2 is a coated polyethylene obtained by extrusion compounding; the temperature of the resin during extrusion compounding cannot exceed 280°C.

[0026] Further, the barrier layer 3 is a soft aluminum foil, and the thickness of the aluminum foil is between 7 microns and 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com