Preparation of self-immobilization type catalyst and catalytic olefin epoxidation method

A catalyst and self-fixing technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of poor recycling effects, large amounts of carriers, and catalyst removal And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

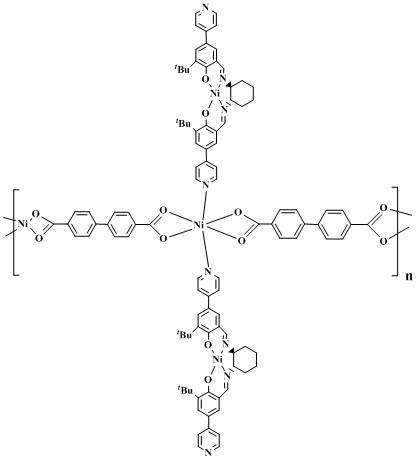

[0016] Example 1: Chiral coordination polymer self-supporting olefin epoxidation catalyst 1

[0017] At room temperature, 0.1 mmol of the complex ( R,R )salen (Ni), 0.1mmol 4,4'-biphenyldicarboxylic acid and 0.1mmol nickel nitrate hexahydrate were added to 100ml N,N'-dimethylformamide solution, and the temperature was gradually raised to 60°C. After 12 hours of reaction, Cool down to room temperature, filter, wash with N,N'-dimethylformamide, wash with ethanol, and dry in vacuum to obtain chiral coordination polymer self-supporting olefin epoxidation catalyst 1.

Embodiment 2

[0018] Example 2: Chiral coordination polymer self-supporting olefin epoxidation catalyst 2

[0019] At room temperature, 2000 mmol of the complex ( S,S )salen (Ni), 2000mmol 4,4'-biphenyldicarboxylic acid and 2000mmol nickel chloride hexahydrate, added to 2000ml N,N'-dimethylformamide solution, gradually heated to 80 ° C, after 48 hours of reaction, the to room temperature, filtered, washed with N,N'-dimethylformamide, washed with ethanol, and dried in vacuum to obtain a chiral coordination polymer self-supporting olefin epoxidation catalyst 2.

[0020]

Embodiment 3

[0021] Example 3: Self-supporting catalyst 1 catalyzes the epoxidation of styrene

[0022] At 0°C, add 0.01mmol self-supporting catalyst 1, 0.15mmol sodium hypochlorite (the ratio of the two is 1:15), 0.4mmol styrene (the ratio of the three is 1:15:40) to the reaction system, 10ml of dichloromethane, stirred and reacted for 0.5h, filtered, olefin epoxide was extracted with dichloromethane, dried over anhydrous sodium sulfate, separated by column chromatography to obtain 1,2-oxyethylbenzene, conversion rate 56%, selectivity 75%; Catalyst 1 was washed with dichloromethane, washed with ether, dried in vacuum, and recycled.

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com