Manufacturing method of radio frequency identification electronic label

A technology of radio frequency and electronic tags, which is applied to recording carriers used by machines, instruments, computer components, etc., and can solve problems such as non-tight stickers, no contribution to the convenience of cargo logistics, and uneven electronic tags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following describes the embodiments of the present invention in more detail with the accompanying drawings of the specification, so that those skilled in the art can implement them after studying the specification.

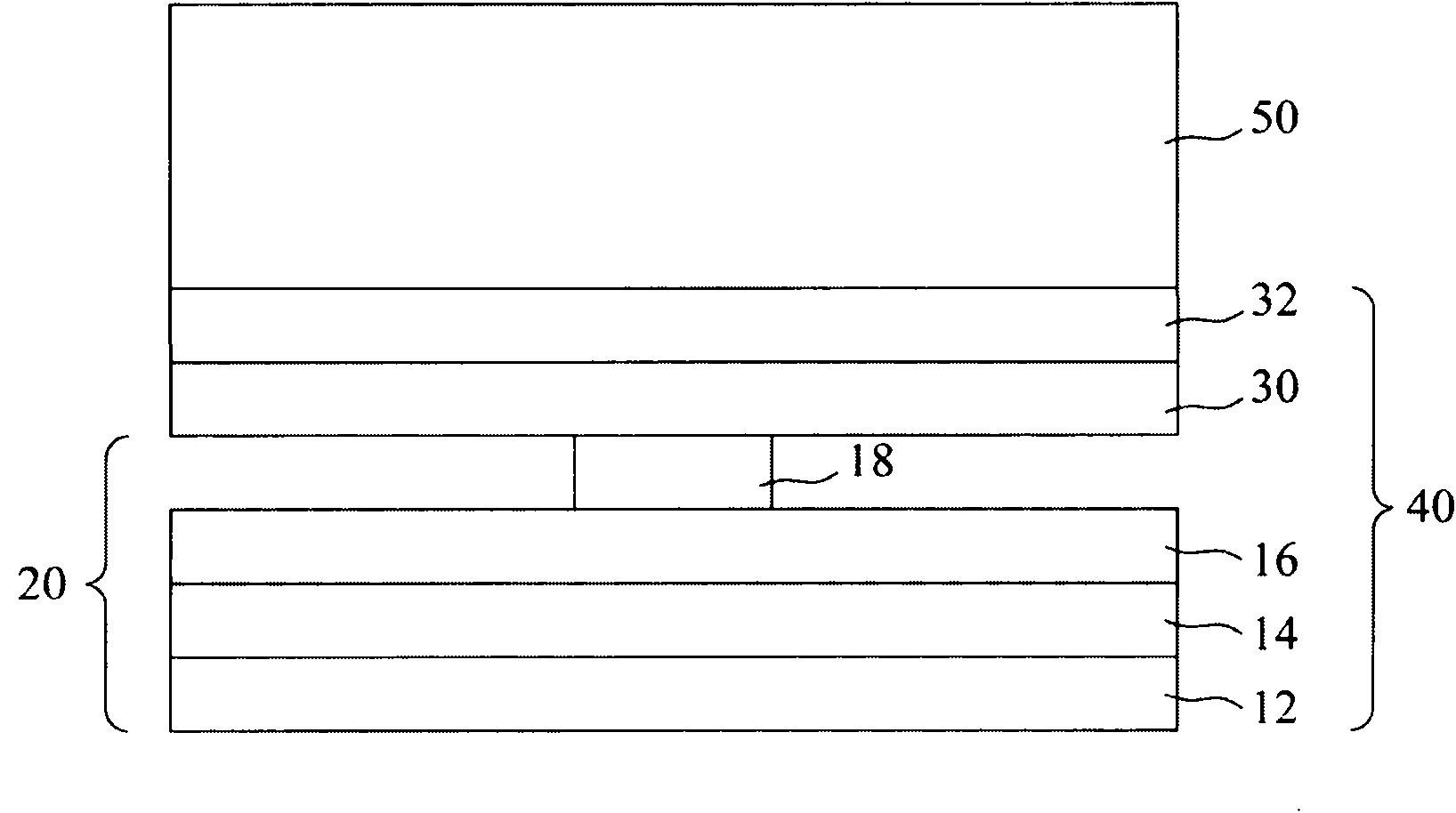

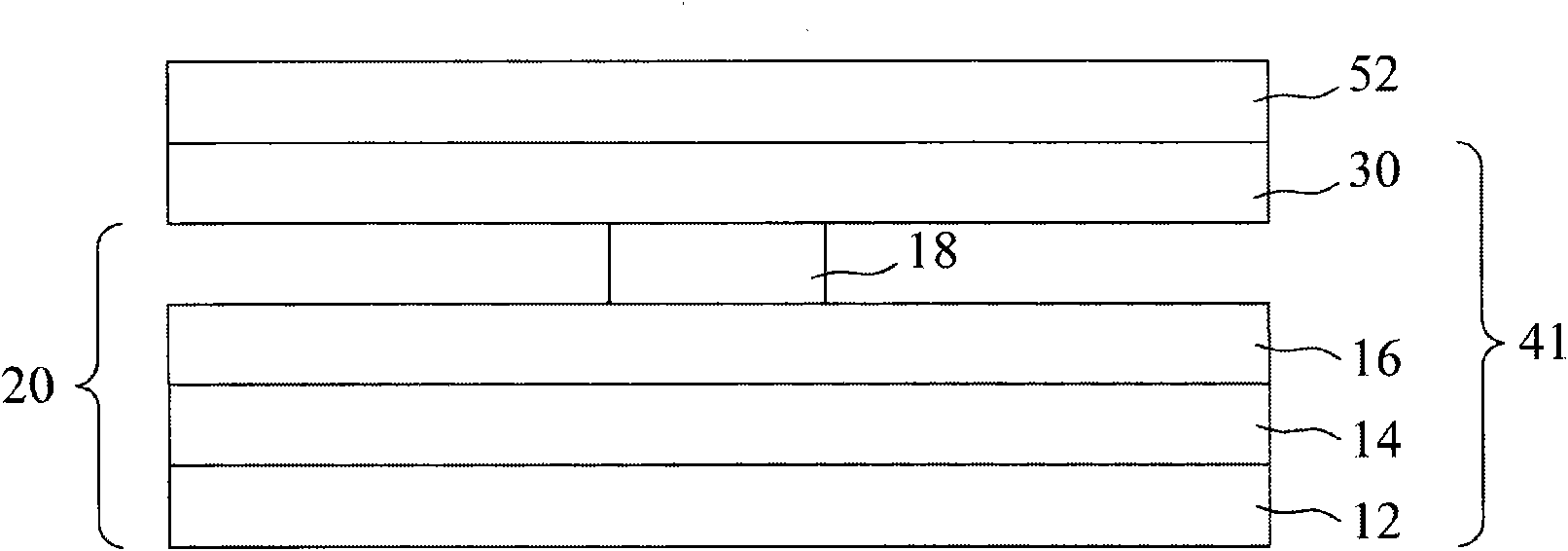

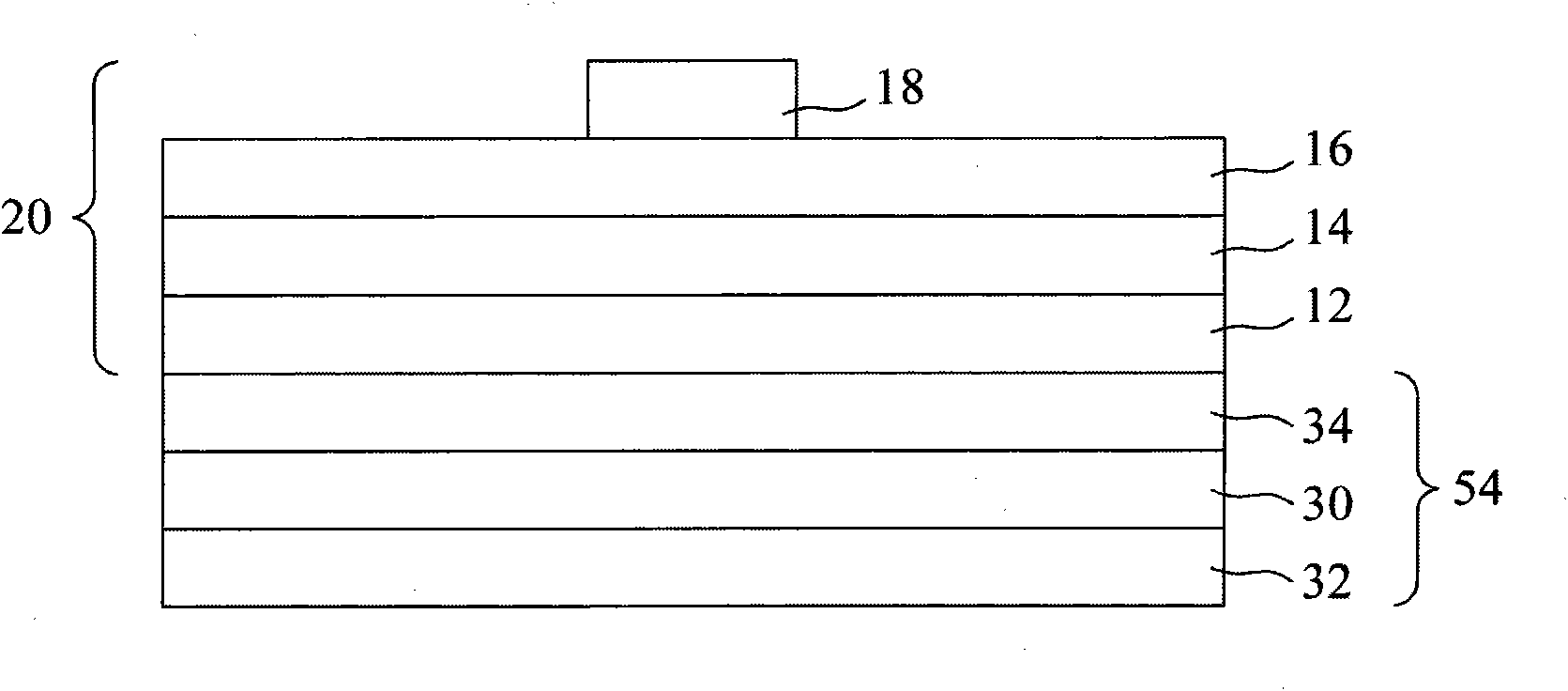

[0015] Refer to figure 1 , Is a schematic diagram of the manufacturing method of the radio frequency identification electronic tag according to the first embodiment of the present invention. Such as figure 1 As shown, the manufacturing method of the first embodiment of the present invention includes: forming an antenna pattern layer 14 with a conductive material on a substrate 12; coating conductive ink on the antenna pattern layer 14 to form a conductive ink layer 16; and placing a radio frequency identification chip 18 is on the conductive ink layer 16, so that the radio frequency identification chip 18 is electrically connected to the antenna pattern layer 14 through the conductive ink layer 16, and forms a substrate 12, an antenna pattern layer 14, a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com