Axial flow wind wheel

An axial flow wind and wind wheel technology, which is applied to the components of the pumping device for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problems of low-energy fluid accumulation, high aerodynamic noise of the wind wheel, etc. To achieve the effect of reducing accumulation, reducing the weight of the wind wheel and motor load, and reducing the energy intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

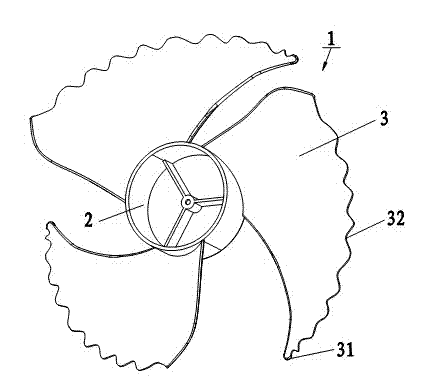

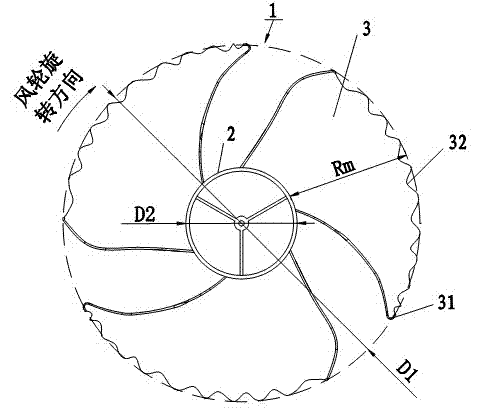

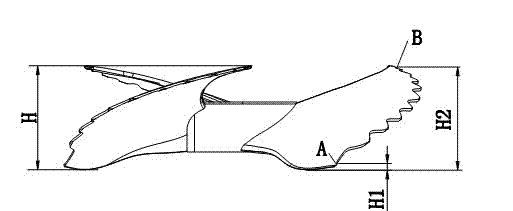

[0016] In each figure, 1 is the axial flow rotor, 2 is the hub, 3 is the blade, 31 is the outer edge of the blade, 32 is the corrugated part of the outer edge of the blade, D1 is the outer diameter of the axial flow rotor, D2 is the diameter of the hub, R m is the blade height, H is the wind rotor height, H 1 is the height of the position A where the outer edge of the blade begins to corrugate, H 2 It is the height of position B where the corrugation of the outer edge of the blade ends.

[0017] see figure 1 The axial flow wind rotor 1 includes three blades 3 arranged on the hub 2. The blades 3 have the same shape and installation angle. The blades 3 are distributed on the hub 2 at equal or unequal intervals around the center axis of rotation of the wind rotor 1. Above, the middle section of the outer edge of the blade 3 is the corrugated part 32 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com