Underground ultrasonic yield-increasing pumping device for coalseam gas

A coalbed methane well, ultrasonic technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of high production and maintenance costs, large energy loss, and many moving parts, so as to reduce gas production costs and improve Efficiency of drainage and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

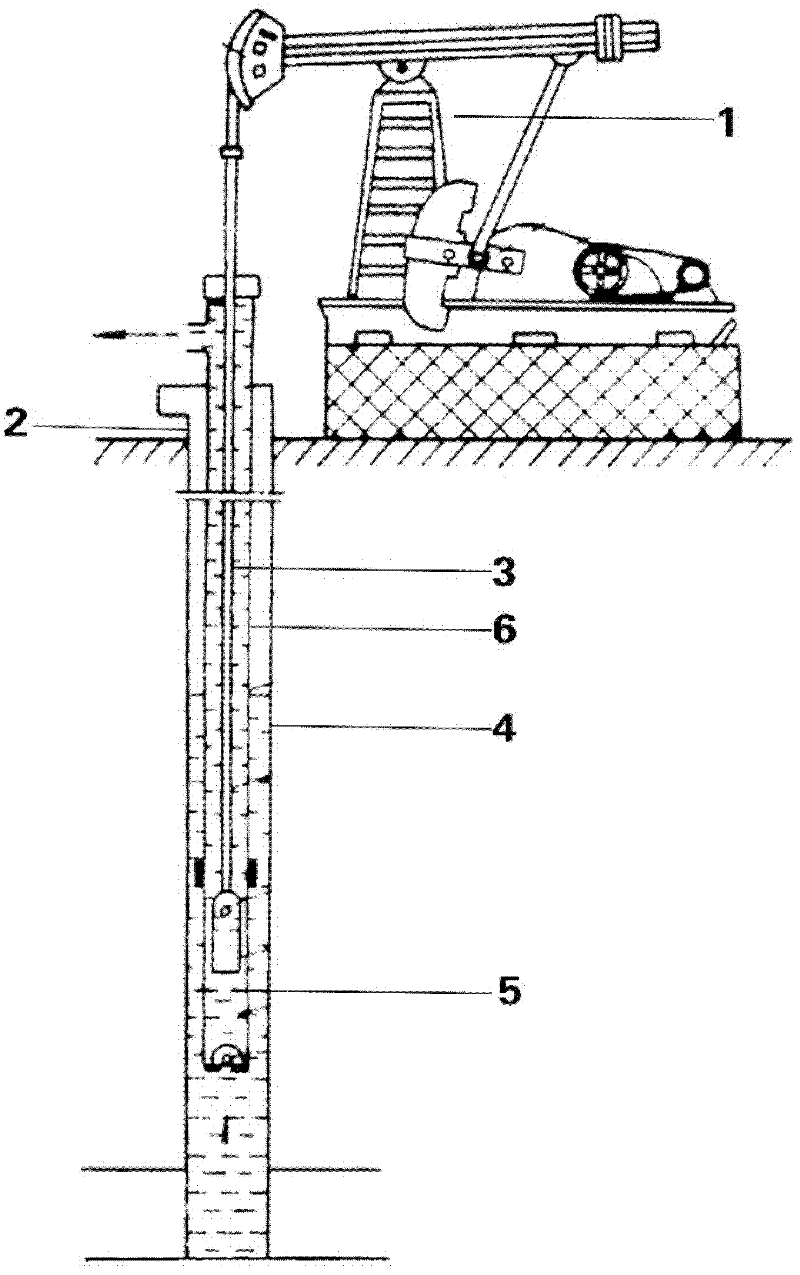

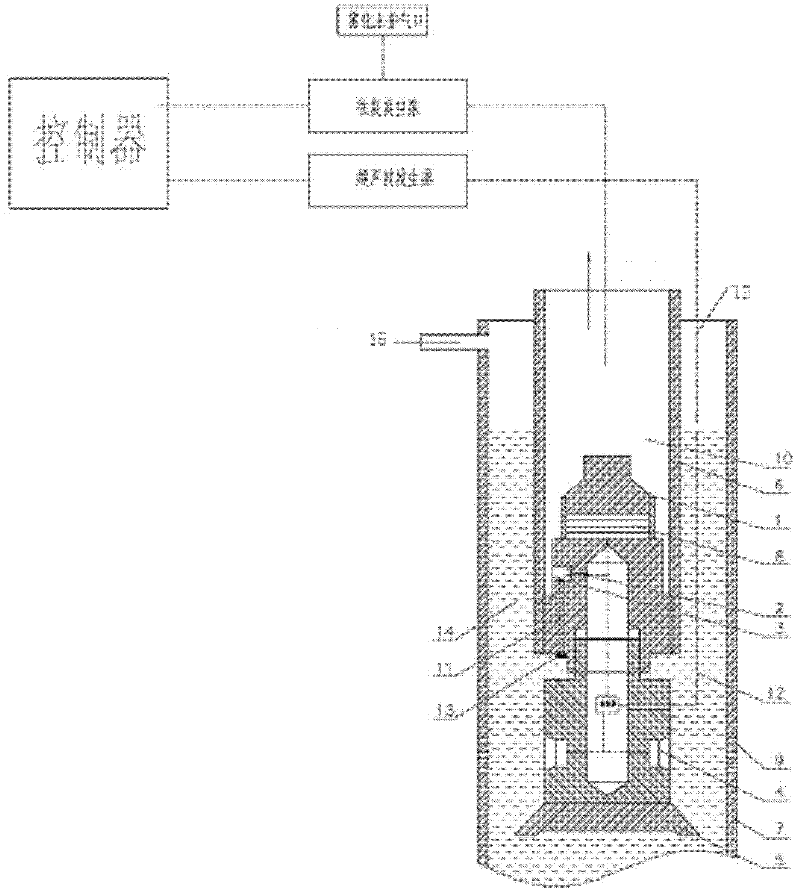

[0028] Below, in conjunction with accompanying drawing and embodiment, the present invention is described in detail; figure 1 It is a schematic diagram of the structure of a system device in the prior art that adopts the "liquid drainage and gas recovery" method and uses the ground pumping unit to drive the oil well pump. figure 2 It is a structural schematic diagram of a device supporting the ultrasonic stimulation and atomization extraction process of coalbed methane underground in the present invention. From figure 1 It can be seen that the surface pumping unit 1 drives the oil pump 5 through the sucker rod 2, and the piston of the oil pump 5 reciprocates up and down to continuously pump out the bottom water to reduce the height of the liquid column and make the pressure at the perforation position Above the liquid column pressure, a certain "production pressure difference" is formed; in this way, the desorbed gas of the coal seam flows out from the perforation position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com