Washbasin and closestool water saving system

A water-saving system and washbasin technology, applied in the field of sanitary ware, can solve the problems of wasting water resources and not being able to recycle, and achieve the effect of saving fresh water resources and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

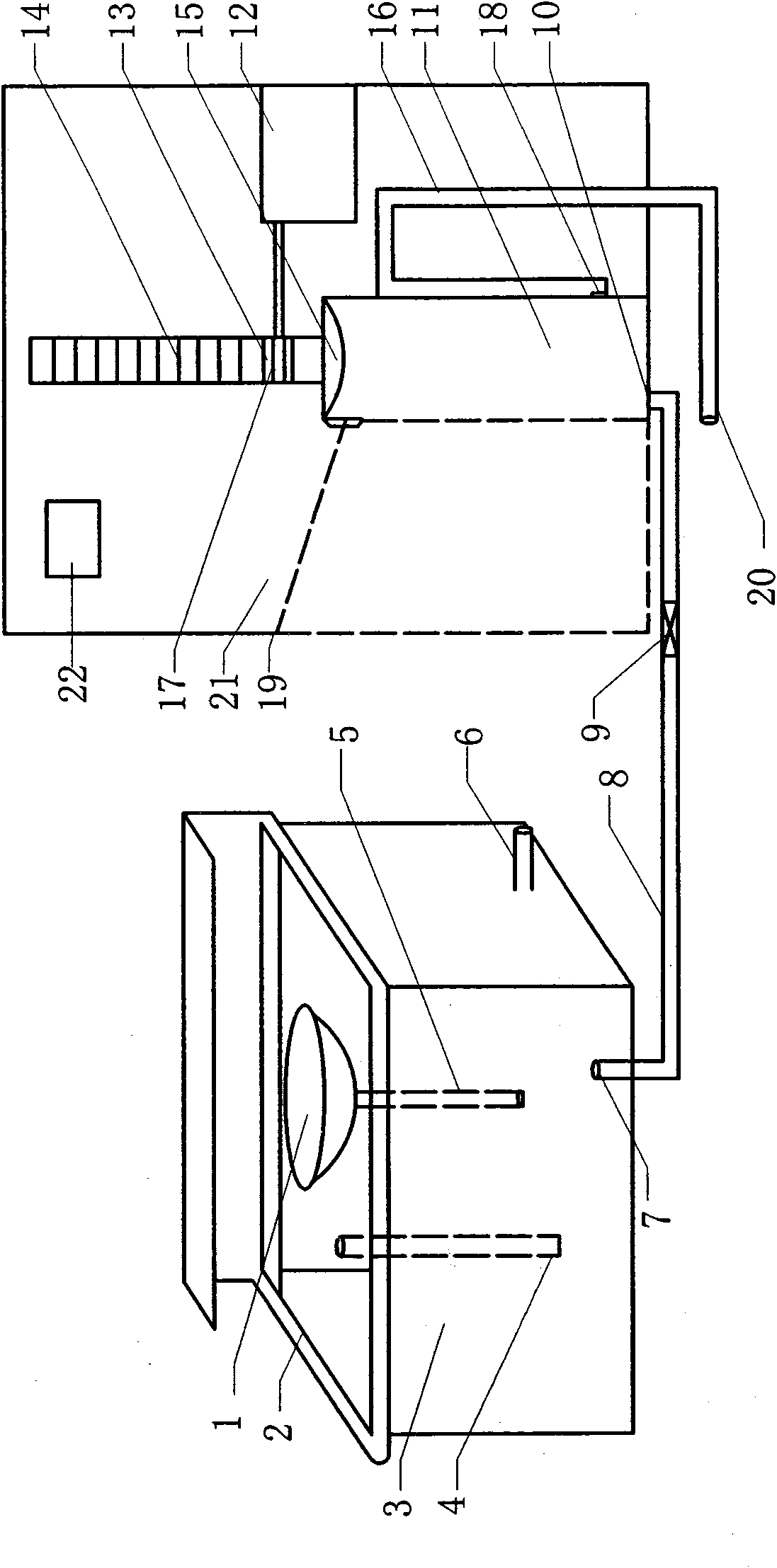

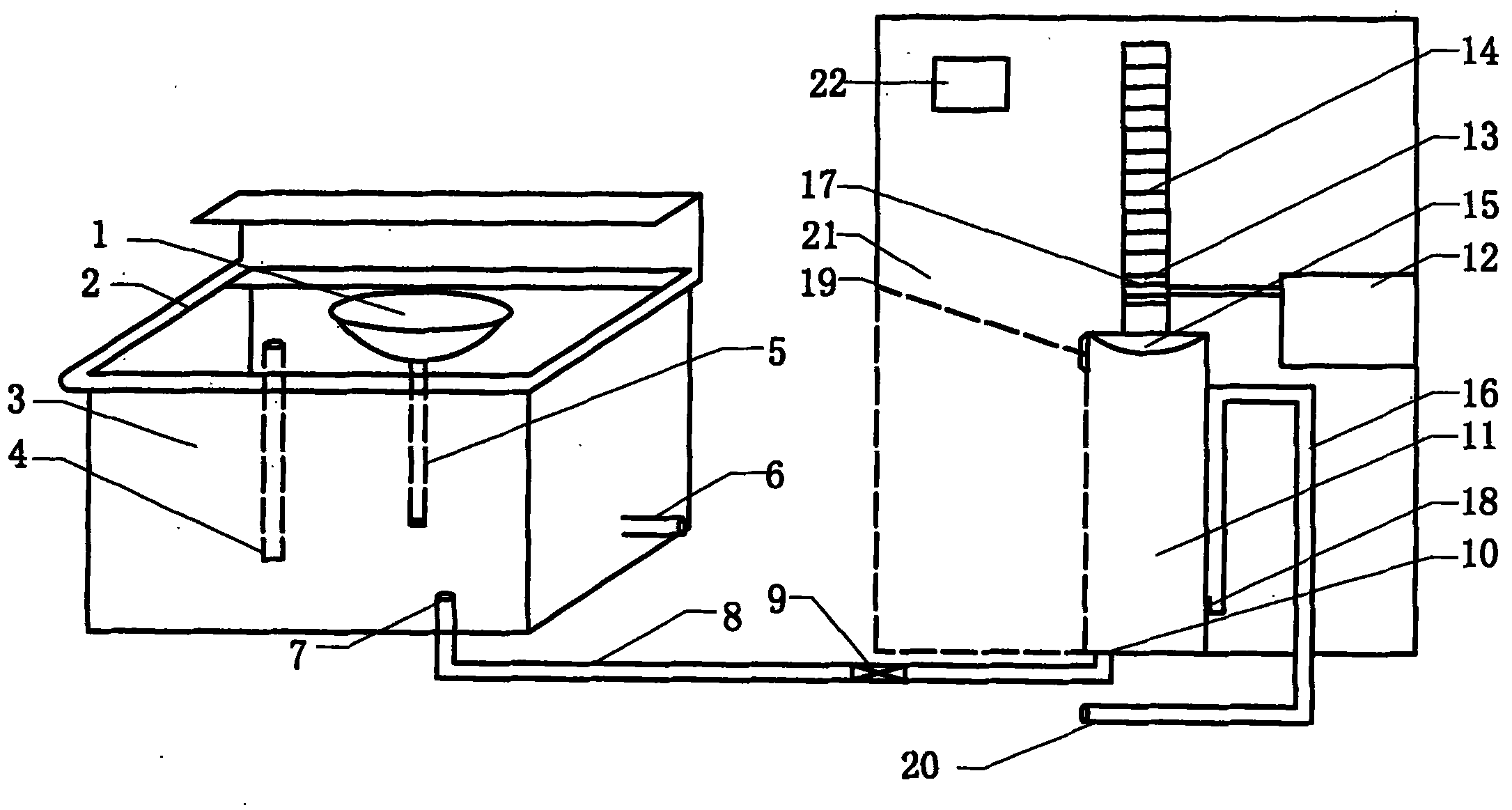

[0009] exist figure 1 In the middle, when the washbasin 1 has water, it flows into the main water tank 3 through the drainer 5, and stores it. The water storage limit of the main water tank 3 is 80 centimeters high. , waste, unscrew the waste discharge hole 6 to release; the water of the main water tank 3 directly enters the diversion pipe 8 through the diversion hole 7, and after passing through the reverse flow resistor 9, enters the booster chamber 11 from the water inlet 10 of the booster chamber, At this time, the main water tank 3, the pressurization chamber 11, and the downstream supercharger 16 have the same horizontal plane height, and the power supply assembly 22 is turned on. After the motor 12 is energized, the gear 13 is driven to rotate, forcing the straight row gear bar 14 to move downward, and the straight row gear bar 14 is forced to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com