Method for preparing high carbon ferromanganese

A technology of high-carbon ferromanganese and high-iron ore, which is applied in the field of manganese alloy production, can solve the problems of lower product output and quality, decline in economic indicators, and poor gas permeability of furnace materials, so as to increase heat energy utilization, improve gas permeability, and improve The effect of furnace condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

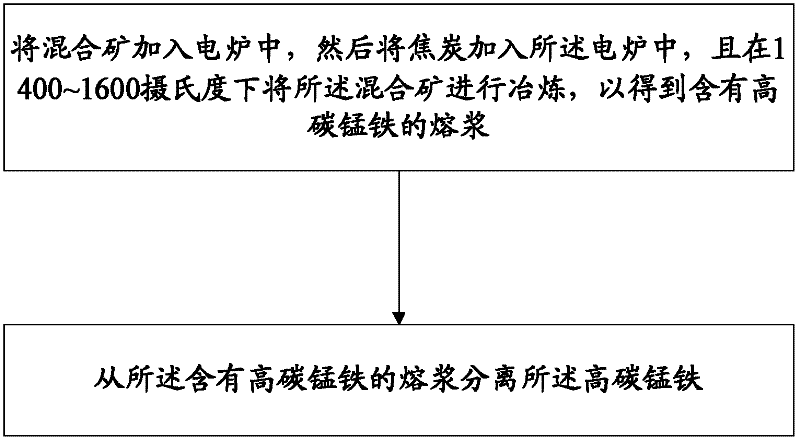

Method used

Image

Examples

Embodiment 1

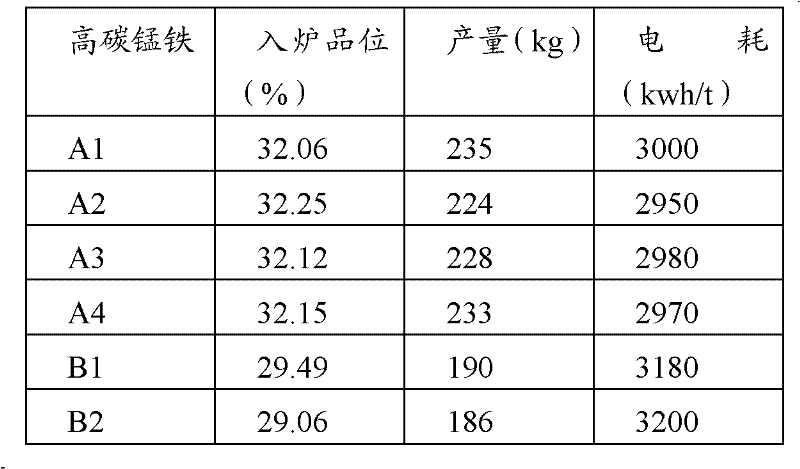

[0041]Add 110kg of composite pellets with a particle size of 50mm, 240kg of magnetically separated manganese-rich ore with a particle size of 70mm, 90kg of South African ore with a particle size of 10mm, 100kg of primary ore with a particle size of 70mm, and 130kg of South African high-speed iron ore with a particle size of 50mm into the silo respectively , transported to the top of the 12500KVA submerged heat electric furnace through the belt under the silo, and then fed into the electric furnace through the feeding port on the top of the electric furnace to form a mixed ore. Next, add 114kg of coke, and smelt the mixed ore at 1500 degrees Celsius to obtain a molten slurry containing high-carbon ferromanganese. Continuous production, once every 4 hours. After being released from the furnace, the molten slurry containing high-carbon ferromanganese is poured into a mold for casting to form high-carbon ferromanganese A1. The furnace grade, output and power consumption were meas...

Embodiment 2

[0046] Add 110kg of composite pellets with a particle size of 70mm, 240kg of magnetically separated manganese-rich ore with a particle size of 80mm, 90kg of South African ore with a particle size of 50mm, 100kg of primary ore with a particle size of 80mm, and 130kg of South African high-speed iron ore with a particle size of 80mm into the silo respectively , transported to the top of the 12500KVA submerged heat electric furnace through the belt under the silo, and then fed into the electric furnace through the feeding port on the top of the electric furnace to form a mixed ore. Next, 134kg of coke was added, and the mixed ore was smelted at 1400 degrees Celsius to obtain a molten slurry containing high-carbon ferromanganese. Continuous production, once every 4 hours. After being released from the furnace, the molten slurry containing high-carbon ferromanganese is poured into a mold for casting to form high-carbon ferromanganese A2. The furnace grade, output and power consumpt...

Embodiment 3

[0048] Add 110kg of composite pellets with a particle size of 60mm, 240kg of magnetically separated manganese-rich ore with a particle size of 75mm, 90kg of South African ore with a particle size of 30mm, 100kg of primary ore with a particle size of 75mm and 130kg of South African high-speed iron ore with a particle size of 60mm into the silo , transported to the top of the 12500KVA submerged heat electric furnace through the belt under the silo, and then fed into the electric furnace through the feeding port on the top of the electric furnace to form a mixed ore. Next, add 124kg of coke, and smelt the mixed ore at 1450 degrees Celsius to obtain a molten slurry containing high-carbon ferromanganese. Continuous production, once every 4 hours. After being released from the furnace, the molten slurry containing high-carbon ferromanganese is poured into a mold for casting to form high-carbon ferromanganese A3. The furnace grade, output and power consumption were measured, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com