Uniform wiring device adopting split nut

A technology of opening and closing nuts and wiring devices, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems of overlapping power lines and uncertain number of turns of winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

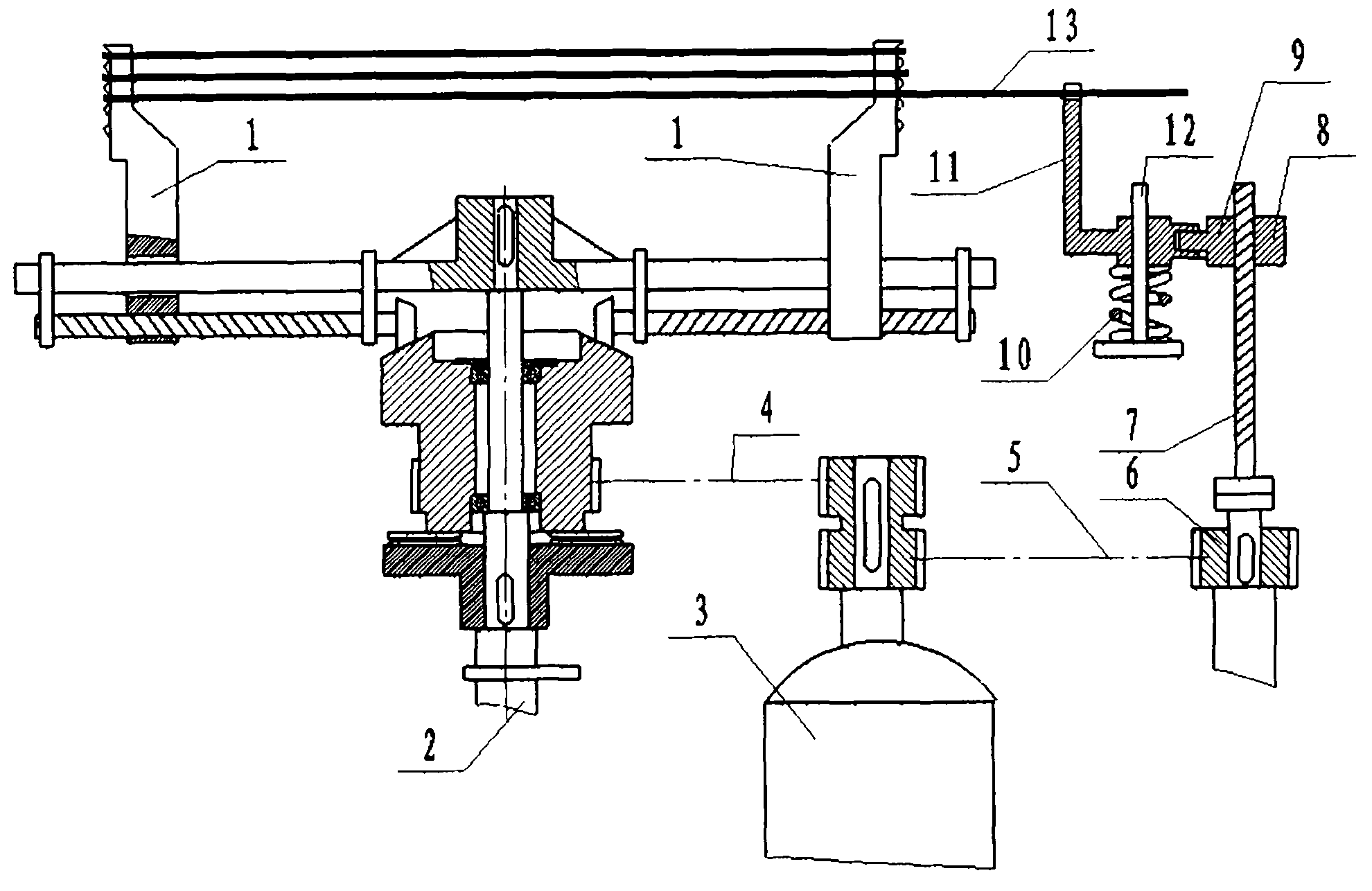

[0011] Such as figure 1 As shown, when winding the power cord (13), the winding main shaft (2) and all its parts will form a whole, and there will be no relative movement between the parts. The stepping motor (3) makes the whole system rotate together through the toothed belt 1 (4), realizing winding. Simultaneously, the right half split nut (8) and the left half split nut (9) are combined under the pneumatic drive to form a screw pair with the wiring screw (7). The toothed belt 2 (5) drives the wiring screw (7) to rotate, and the wiring board (11) moves at a constant speed while holding the power cord (13) under the cooperation of the two half nuts and the wiring screw (7), so as to realize uniform wiring . The winding and uniform wiring parts are driven by the same stepper motor (3).

[0012] After the wiring is completed, the stepper motor (3) does not need to rotate in the opposite direction to drive the wiring board (11) back to the initial position. But make two half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com