Wire winding shaft

The technology of a take-up reel and a take-up reel is applied in the field of take-up reels, which can solve the problems of inconvenient installation and disassembly of the device, a single-aperture take-up reel, and high production costs, and achieve the effects of simple structure, improved production efficiency, and reduced production costs.

Inactive Publication Date: 2012-03-14

JIANGSU BADA CABLE

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to propose a wire take-up reel with simple structure, easy to use, and capable of using multiple aperture take-up reels, aiming at the problems that the current take-up spool can only use a single-aperture take-up reel, the production cost is high, and the installation and disassembly of the device is inconvenient. It saves production cost and improves production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

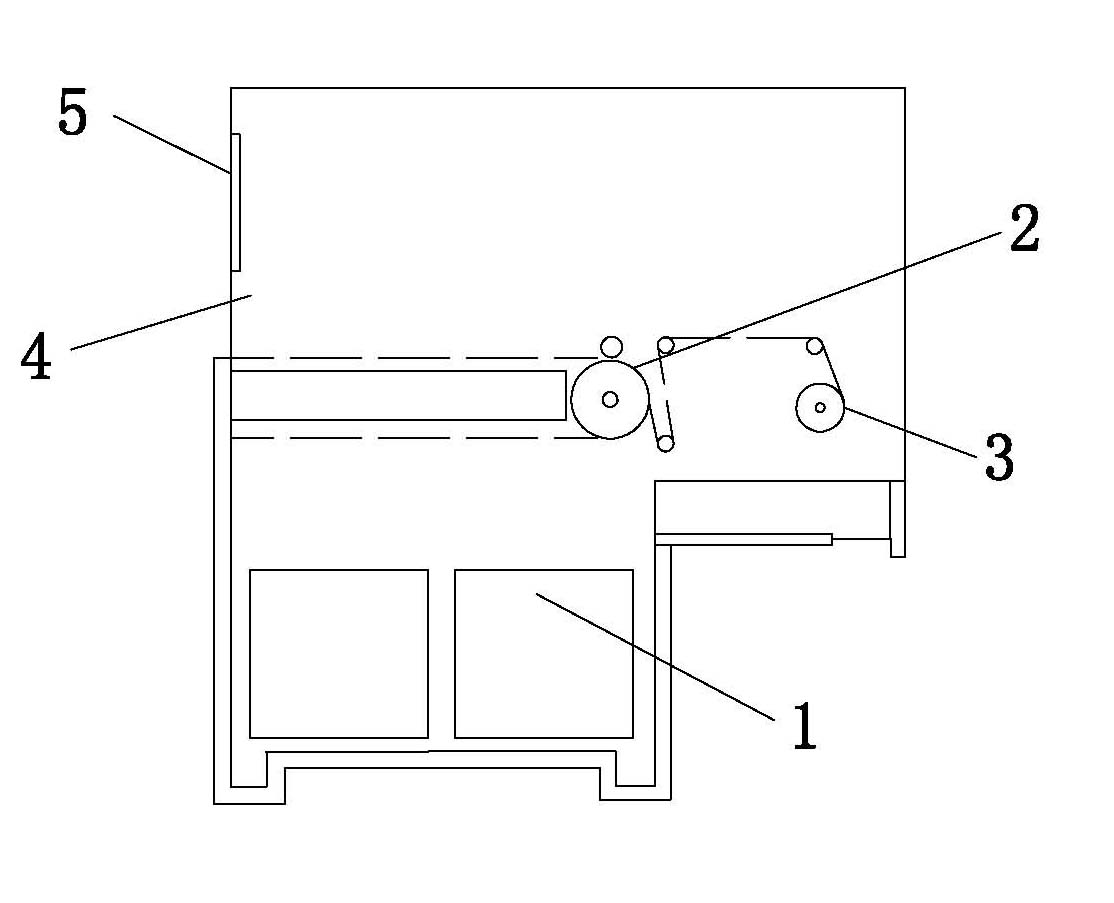

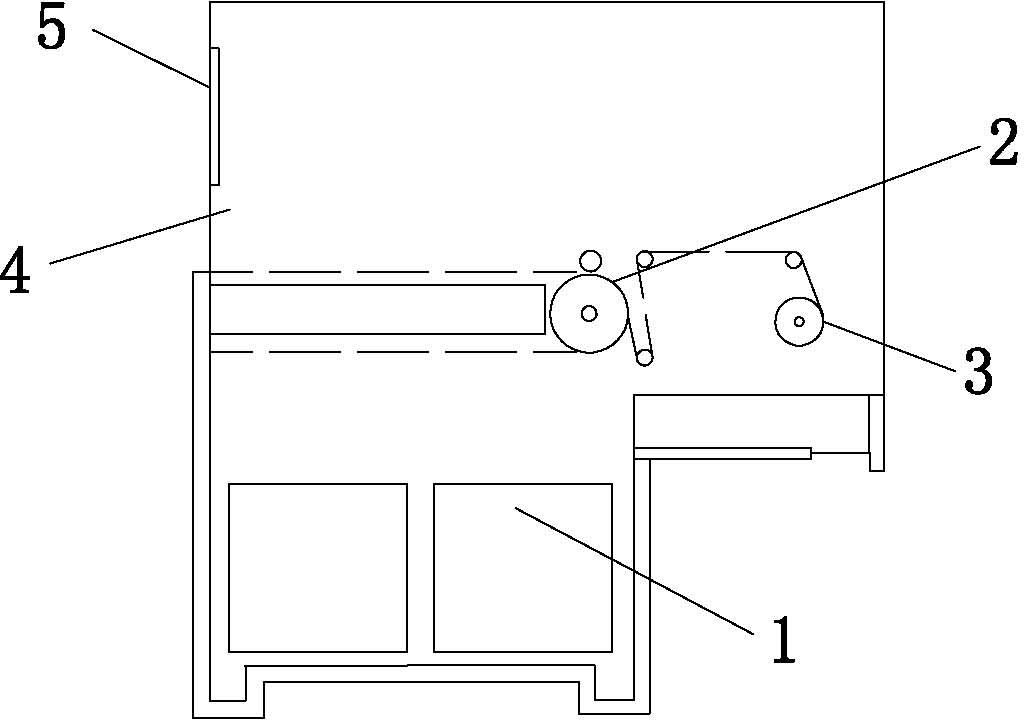

The invention discloses a wire winding shaft. The wire winding shaft is mounted on a wire winding machine; a wire winding disk is sleeved on the wire winding shaft for winding wire; the edge of the wire winding shaft is of a step shape; and the diameter of the wire winding shaft is gradually increased from top to bottom layer by layer. The wire winding shaft disclosed by the invention has simple structure, and is convenient to use; as the wire winding shaft can directly use the wire winding disks of various apertures, the operator is not required to manually cut wire and replace the wire winding shaft through an operation panel of the wire winding machine, thereby realizing continuous production, saving the production cost and improving the production efficiency.

Description

technical field [0001] The invention relates to a wire take-up shaft, in particular to a wire take-up shaft used in a wire take-up machine and applicable to wire take-up reels of different sizes. Background technique [0002] The winding machine is also called the winding device, which is a device for winding films, strips, monofilaments, hoses and coated wires with rollers. According to its winding method, there are two types of center winding machine and surface winding machine. [0003] Existing winders usually include secondary traction rollers, traction motors, cutting knife holders, winding rollers, winding shafts and the like. During the production process, when it is necessary to assemble the take-up reels with different diameters and sizes, it is usually necessary to replace the take-up spool of the corresponding size. The operator needs to manually cut the wire and replace the take-up shaft through the operation panel of the wire take-up machine, which cannot ach...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65H54/547

Inventor 施昕昊

Owner JIANGSU BADA CABLE

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com