Dry and wet composite mixing equipment for power particles

A dry-wet, granule technology, applied in clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve the problems of uneconomical sand drying process and high energy consumption, and achieve easy processing and assembly, and reduce energy consumption Cost, the effect of facilitating the layout of multiple silos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment further illustrate the present invention.

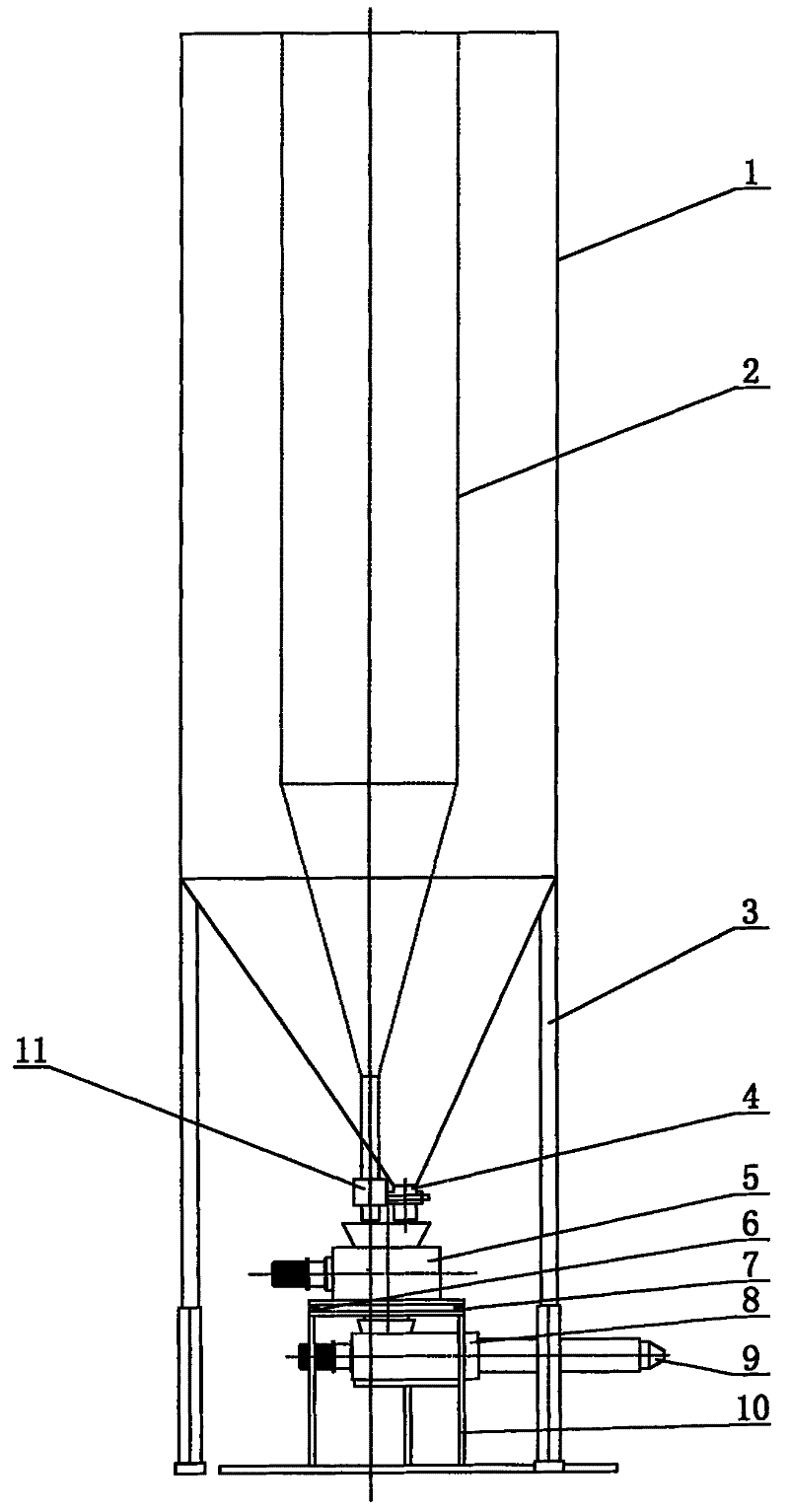

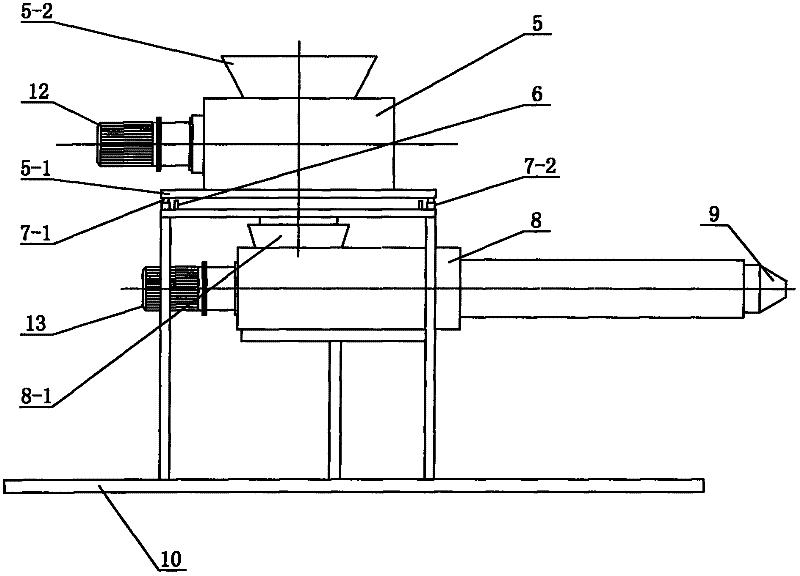

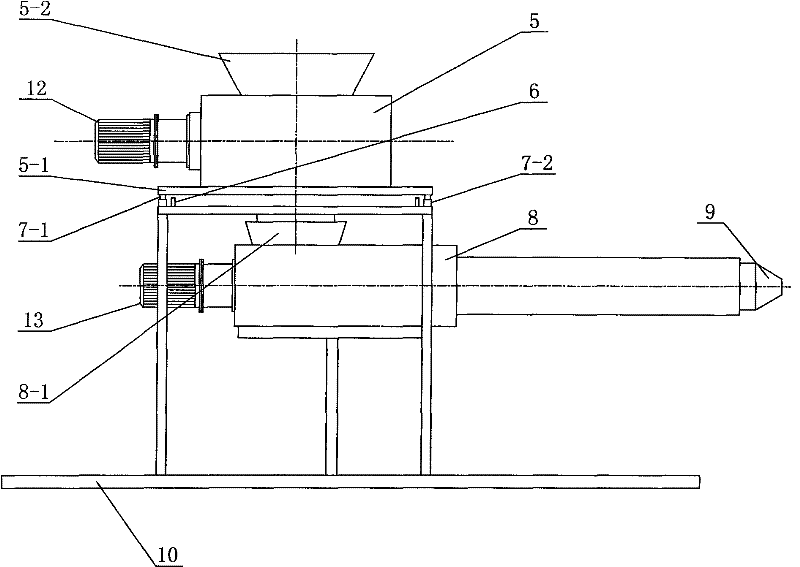

[0019] Such as figure 1 , 2 , The present invention includes a support 10 equipped with a wet mixer 8, and the wet mixer 8 has a dry mix inlet hopper 8-1 and a mortar outlet 9. A load cell 6 is installed on the upper end of the bracket 10 , and a telescopic support seat 7 is also arranged on the upper end of the bracket 10 . The telescopic support base 7 includes a sleeve 7-2 fixed to the wet mixer 8 and a telescopic column 7-1 installed in the sleeve 7-2 in a liftable manner. The wet mixer 8 is driven by the wet mixing motor 13 to perform stirring and wet mixing on the materials therein under the condition of adding water.

[0020] The present invention also includes a dry blender 5 arranged on the upper end of the support 10, the upper end of the dry blender 5 has a feed hopper 5-2, and the lower end has a dry blend outlet and a base plate 5-1, the dry blend The discharge port is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com