Fishbone-shaped string barrel suitable for deep foundation pit concrete warehousing pouring

A technology for concrete and deep foundation pits, applied in construction and infrastructure engineering, etc., can solve problems such as the inability to guarantee the quality of concrete construction, the difficulty of disassembling and assembling concrete pumps, and the separation of grout and aggregate, so as to save cement consumption and reduce material consumption. The effect of labor consumption and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

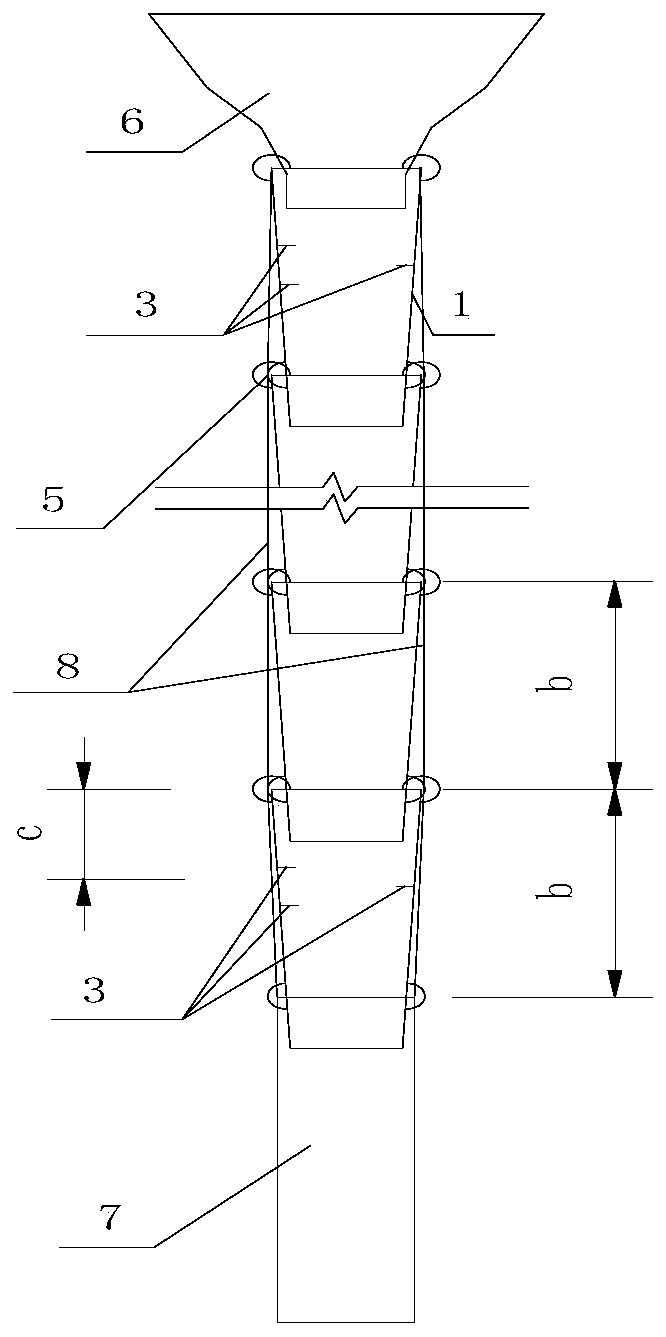

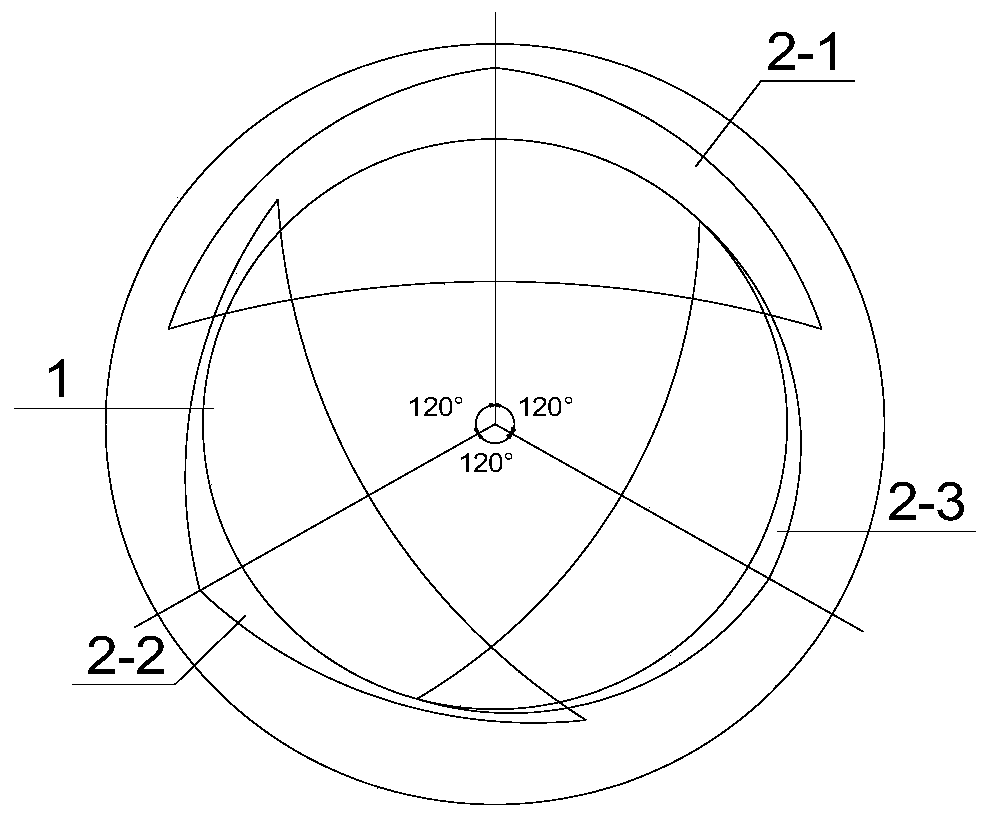

[0035] Such as Figure 1-5 As shown, the present invention provides a fishbone skewer suitable for deep foundation pit concrete pouring into the warehouse, which mainly includes: skewer 1, fishbone-shaped chute 2, fillet weld 3, upper hanger 4, lower hanger 5, set Hopper 6, rubber chute 7 and steel wire rope 8.

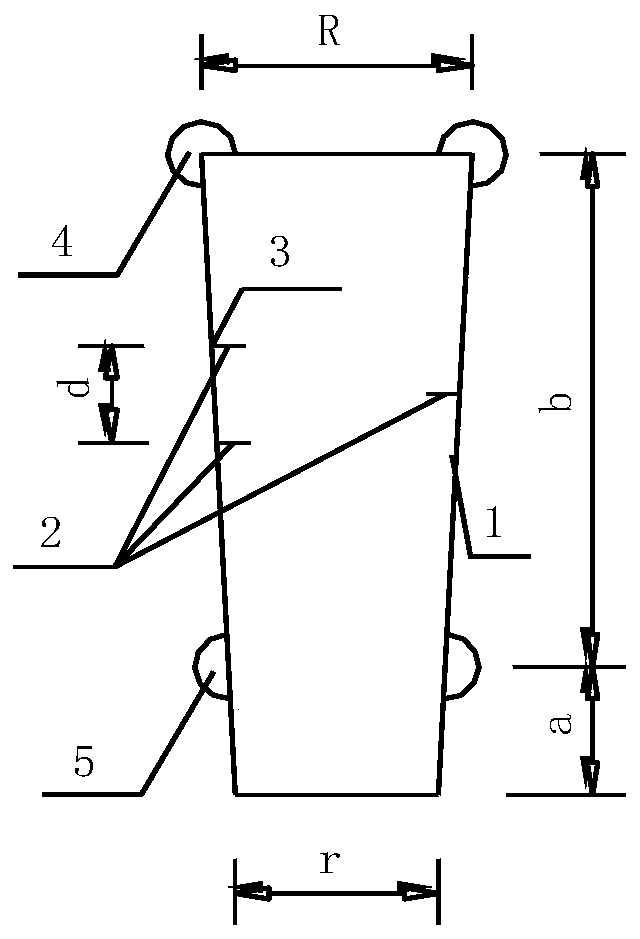

[0036] The string tube 1 is the main force-bearing structure and material delivery channel of the concrete in the warehouse. The string tube 1 is made of 1.2mm thick iron sheet, each section is 1m long, the overlapping section is 0.2m long, and the effective length is 0.8m. The upper diameter of the string tube 1 It is 0.4m, and the lower diameter is 0.3m.

[0037] Such as figure 2 As shown, the top of the stringer tube 1 is provided with an upper lug 4, and the lower end of the stringer tube 1 is provided with a lower lifting ear 5, and the lower end of each upper segment stringer tube 1 is sleeved on the upper end of the lower segment stringer tube 1, and The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com