Storage, transportation and mixed preparation method for building mortar and special device thereof

A technology of special equipment and mortar, which is applied in the field of storage and transportation mixing of construction mortar and its special equipment, which can solve problems such as high energy consumption, and achieve the effects of saving energy, saving energy costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Type A preparation: 50% cement, 12.5% slaked lime, 37.25% heavy calcium as mineral admixture, 0.2% water-retaining agent as additive, and 0.05% air-entraining agent as additive. Mix well to make cement mixture. Class B: Screened, washed (not dried) sand.

[0033] Transport the above two types of raw materials A and B to the construction site respectively, dry mix 40% cement mixture and 60% sand, and then add water with 10-20% solid content for wet mixing to make masonry mortar , for building construction.

[0034] The stated percentages are percentages by weight, the same below.

Embodiment 2

[0036] Type A preparation: 62.5% cement, 12.5% slaked lime, 24.83% heavy calcium as mineral admixture, 0.1% water-retaining agent as additive, 0.05% starch ether as additive, and 0.02% air-entraining agent. Mix well to make cement mixture. Type B: Screen washed (undried) sand.

[0037] The above-mentioned two types of raw materials A and B are divided into sub-tanks and mother tanks of storage and transportation containers in the form of sub-mother tanks and transported to the construction site, dry-mixing 40% of the cement mixture and 60% of the sand, adding 10-20% of the solid content is wet-mixed with water to make plastering mortar for building construction.

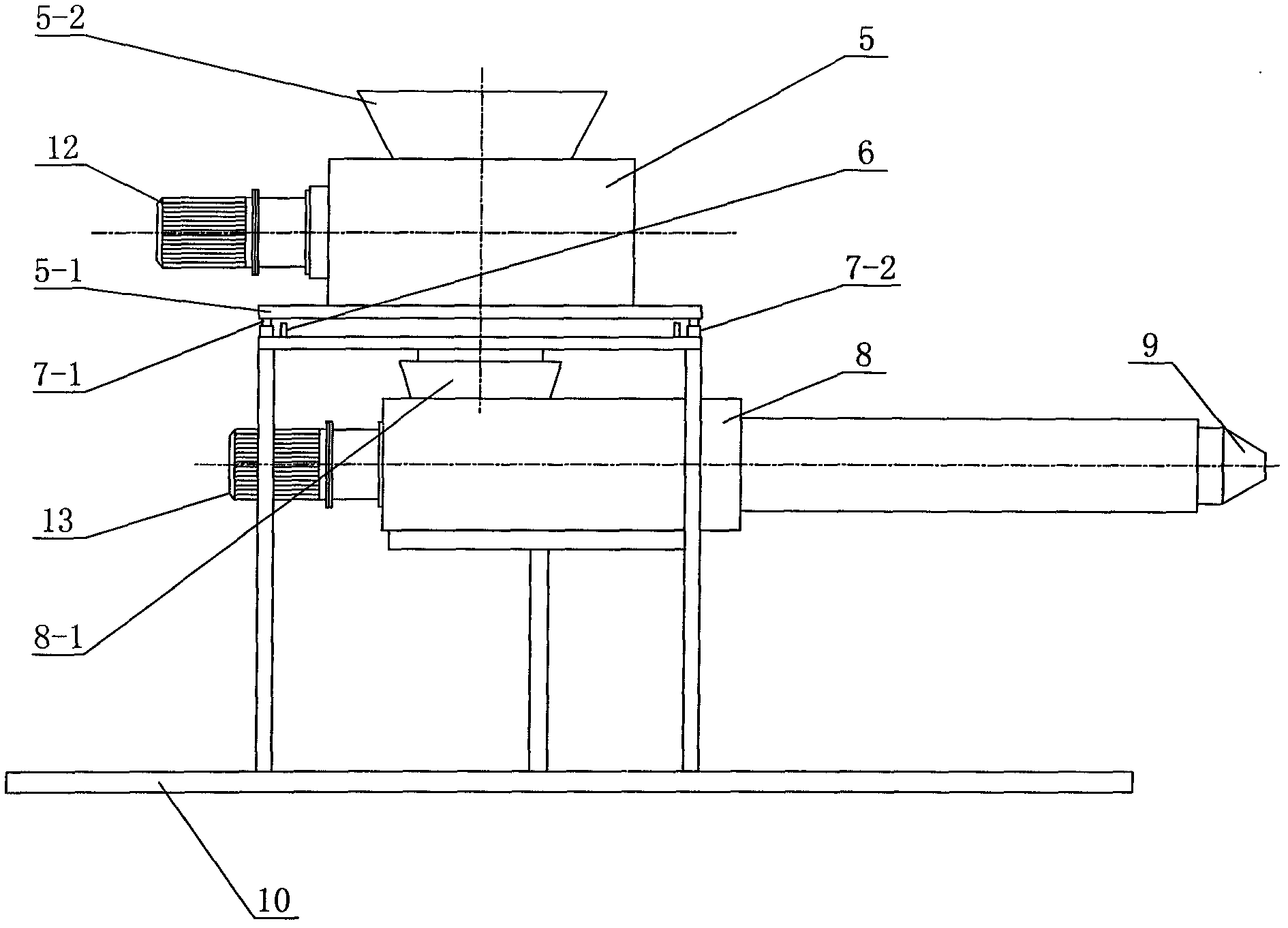

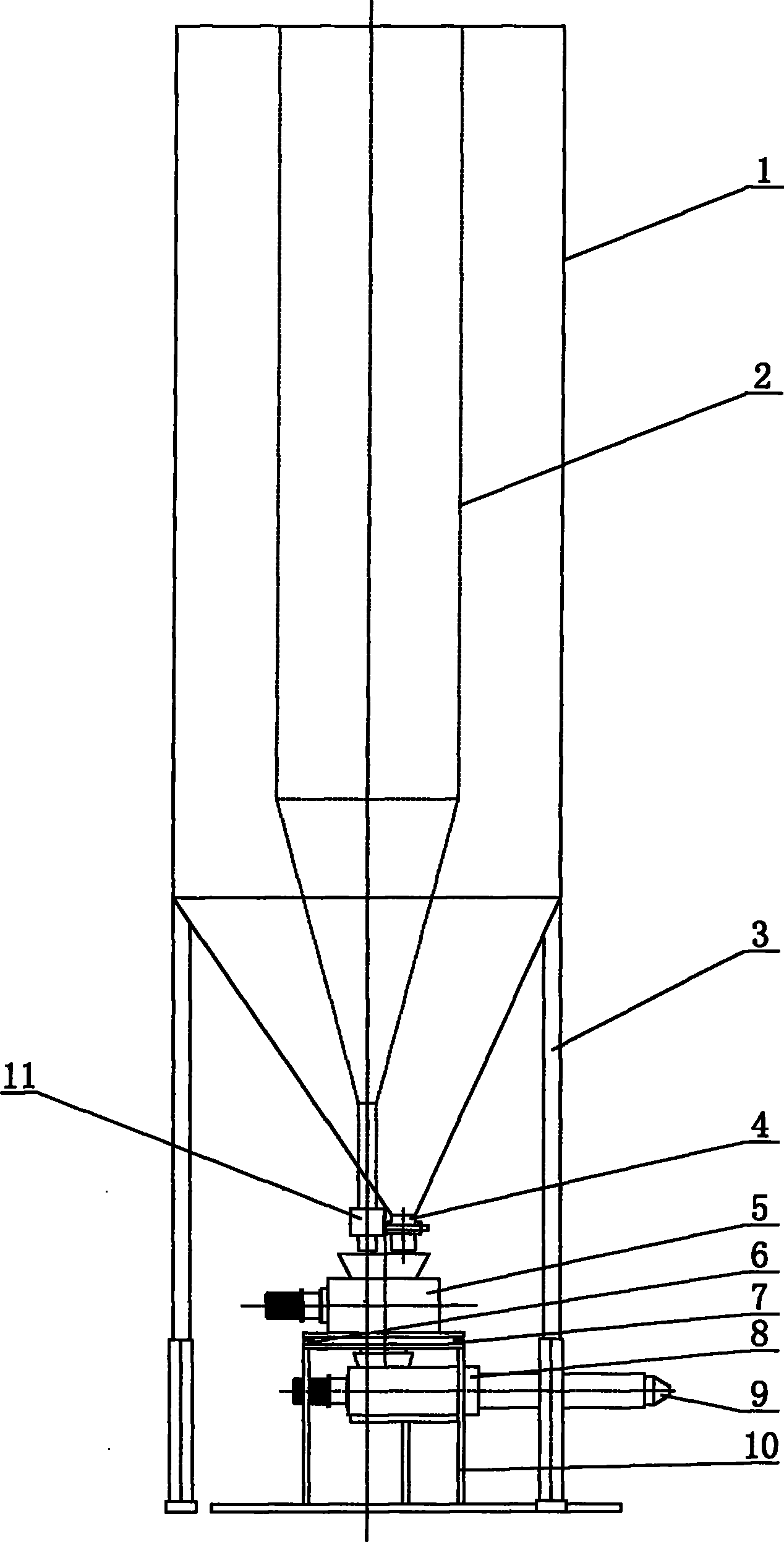

[0038] The weighing batching, dry mixing, and wet mixing of A and B two types of raw materials are completed in a compound mixing equipment; the compound mixing equipment includes a dry mixer and a wet mixer located below the dry mixer, and the dry mixer The discharge port of the wet mixer is located directly abo...

Embodiment 3

[0040] Type A preparation: cement 97.3%, redispersible latex powder 0.9%, water retaining agent 0.3%, water reducing agent 0.9%, defoamer 0.6%. Mix well to make cement mixture. Type B: Screen washed (undried) sand.

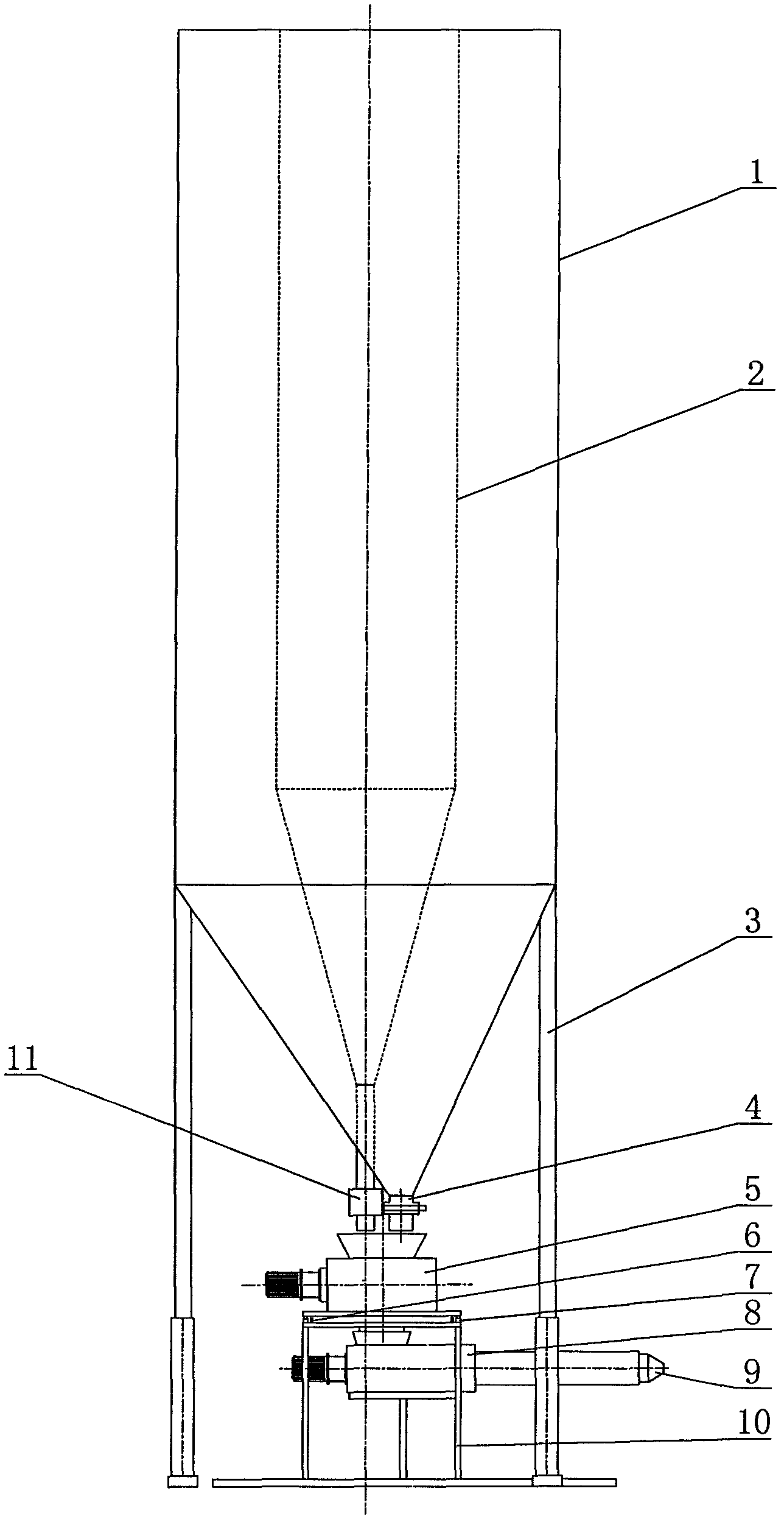

[0041] The above two types of raw materials, A and B, are packed in sub-tanks and mother tanks of specific storage and transportation containers and transported to the construction site, such as figure 1 The storage and transportation container of this specific form comprises a mother tank 1 with a mother tank outlet 4 at the lower end, and at least one cylindrical sub-tank 2 is fixedly installed in the main tank 1, and the sub-tank 2 and The mother tanks 1 have feeding ports respectively. The lower end of the sub-tank 2 has a sub-tank discharge port 11. In order to facilitate discharging into the feed hopper 5-2, the sub-tank discharge port 11 and the mother tank discharge port 4 are close to each other and both Located directly above the feed hopper 5-2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com