Surface treatment device

A surface treatment device and a technology for processing objects, which are applied to the used abrasive treatment device, abrasive feeding device, abrasive and other directions, can solve the problems of projectile scattering and leakage, and achieve the prevention or inhibition of projectiles, prevention or inhibition device The effect of endoleak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

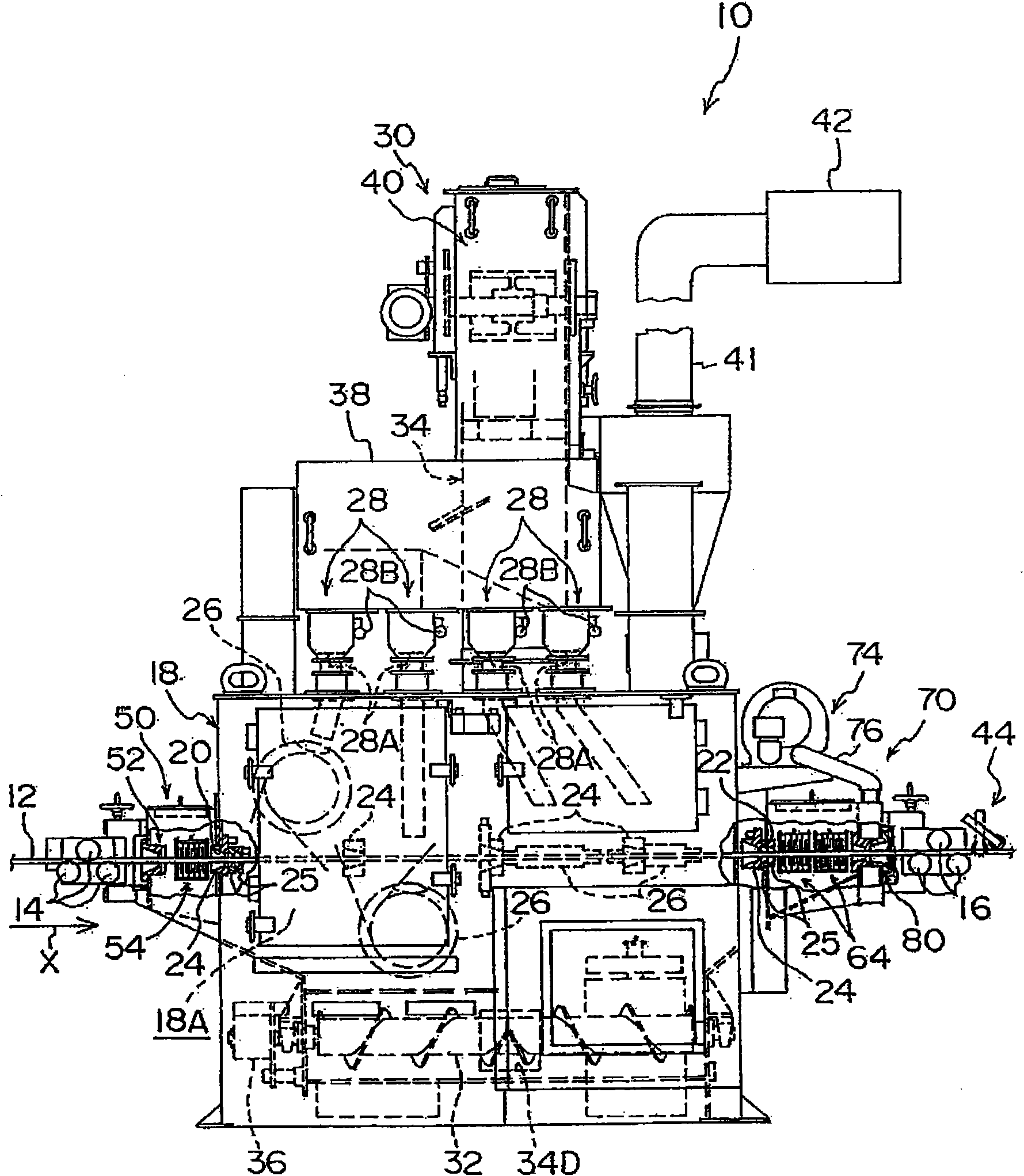

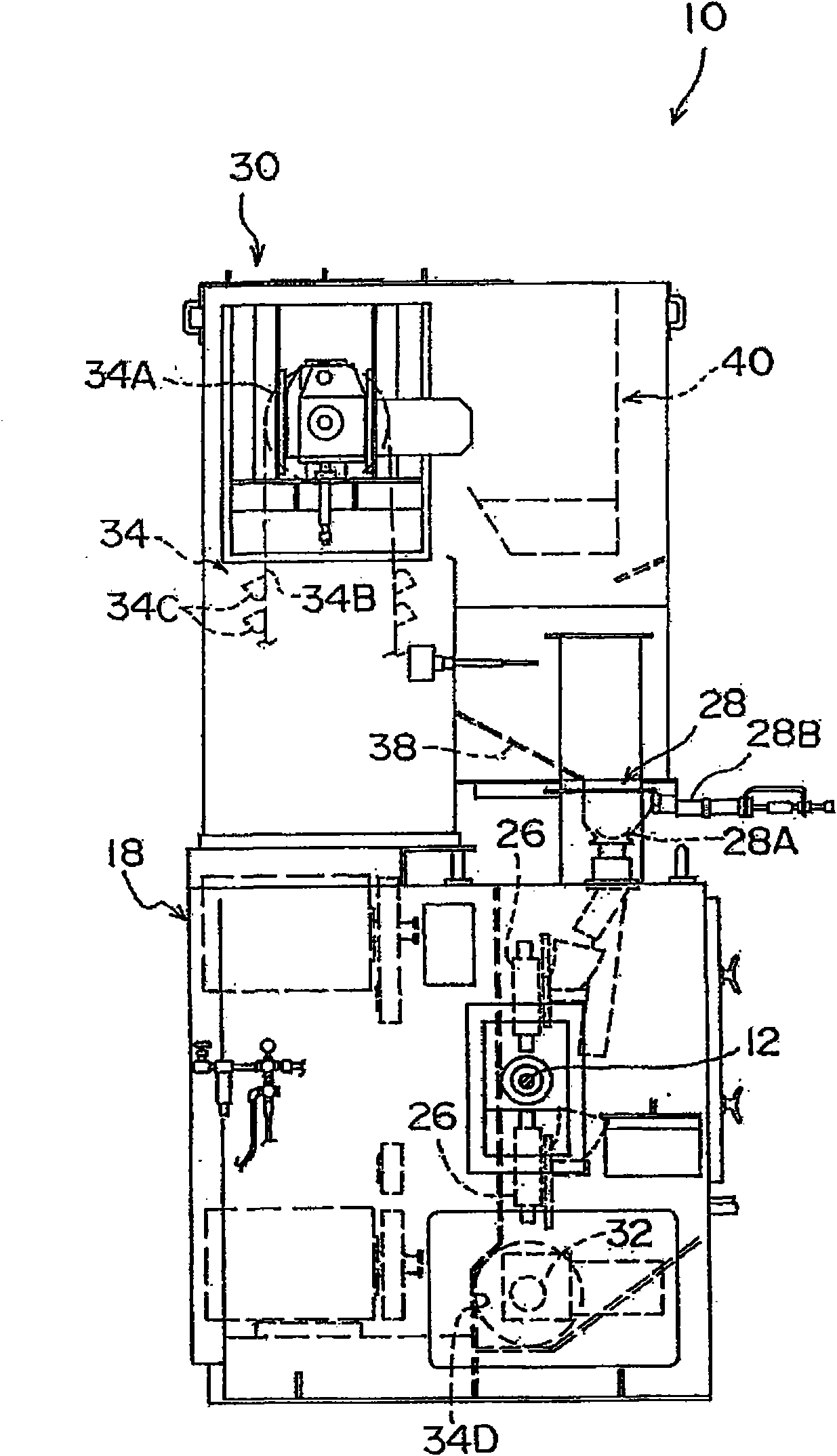

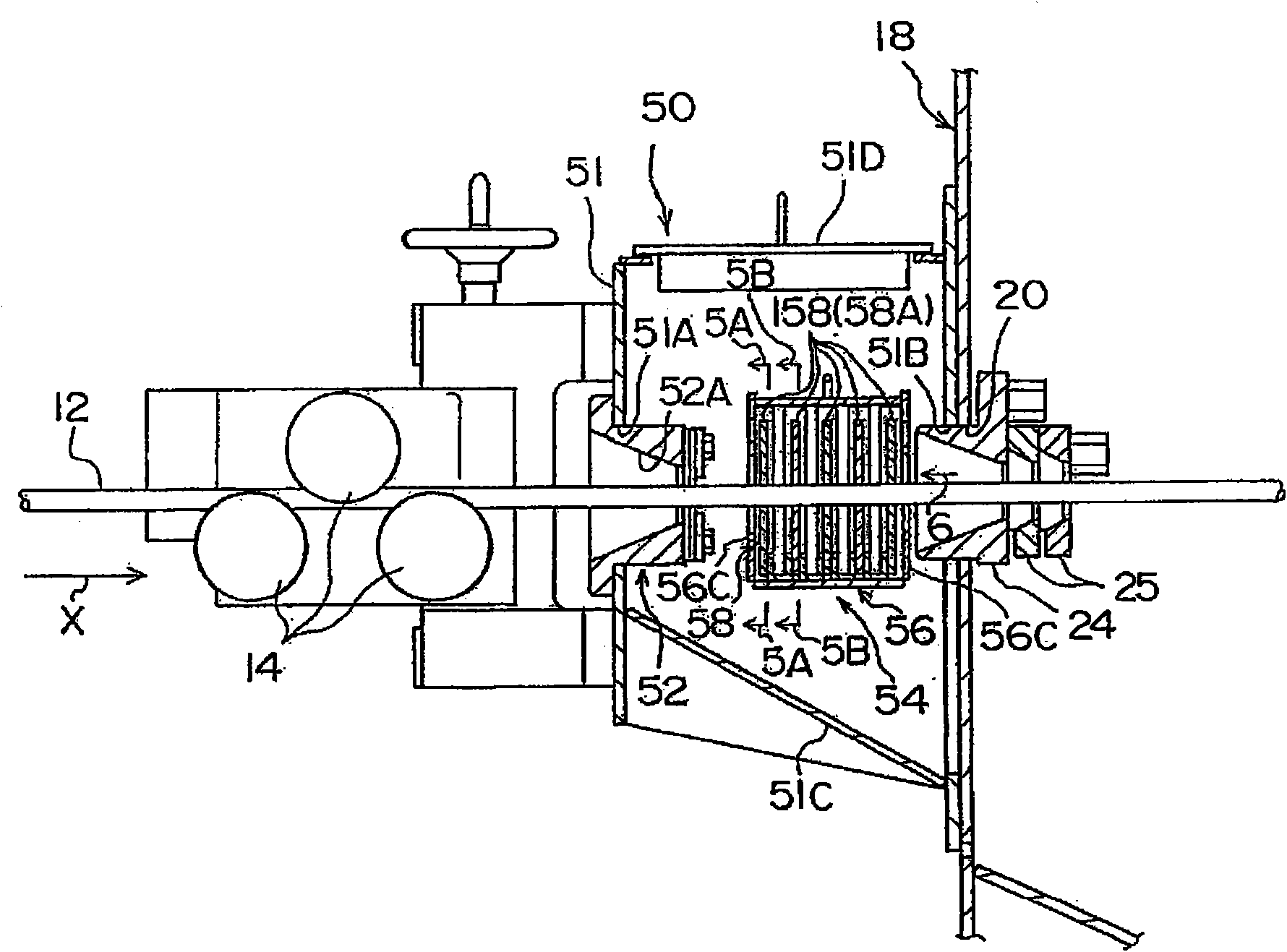

[0048] use Figure 1 to Figure 7 The shot blasting apparatus which is the surface treatment apparatus which concerns on 1st Embodiment of this invention is demonstrated. figure 1 The shot blasting device 10 is shown in a front view, figure 2 The shot blasting device 10 is shown in left side view.

[0049] In addition, in the shot blasting apparatus 10 which concerns on this embodiment, the metal wire rod 12 is made into the object to be processed. Arrow X indicated in the figure shows the conveyance direction of the conveyance wire 12 (hereinafter referred to as "wire conveyance direction").

[0050] in relation to figure 1 A wire supply device (not shown) is arranged on the upstream side (left side in the figure) in the wire feeding direction (wire traveling direction) of the shown shot blasting device 10 . The wire supply device is used to supply the wire 12 to the shot blasting device 10, and includes: an unwinding part for winding the wire 12 before the shot blasting ...

no. 2 Embodiment approach

[0088] Next, use Figure 8 Figure 10 The shot blasting apparatus of the surface treatment apparatus which concerns on 2nd Embodiment of this invention is demonstrated. Figure 8 In the front view, the shot blasting apparatus 90 which concerns on the 2nd Embodiment of this invention is shown, Figure 9 The shot blasting device 90 is shown in a left side view, Figure 10 The shot blasting device 90 is shown in right side view. As shown in the above-mentioned figure, in the shot blasting device 90, the same as the shot blasting device 10 related to the first embodiment (refer to figure 1 ) The difference is to replace the screw conveyor 32 (refer to figure 1 ), and an inclined portion 92 is formed at the bottom of the chamber 18 . Other configurations are basically the same as those of the first embodiment. In this way, the same reference numerals are assigned to components substantially the same as those in the first embodiment, and description thereof will be omitted.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com