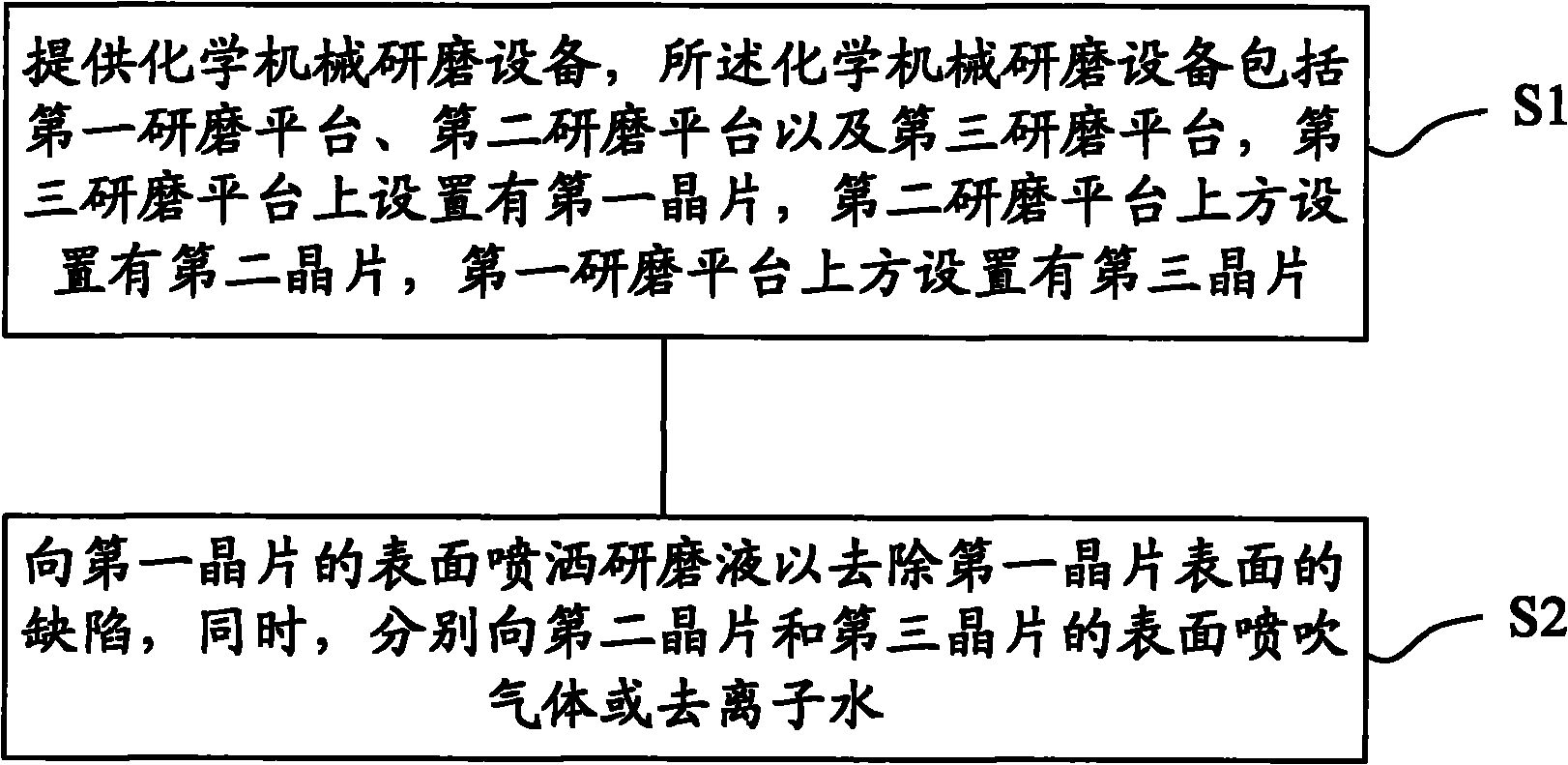

Reworking method for chemical mechanical lapping process

A chemical-mechanical and grinding technology, applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of declining yield of semiconductor devices and easy contamination of wafers, and achieve the effect of improving yield and preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

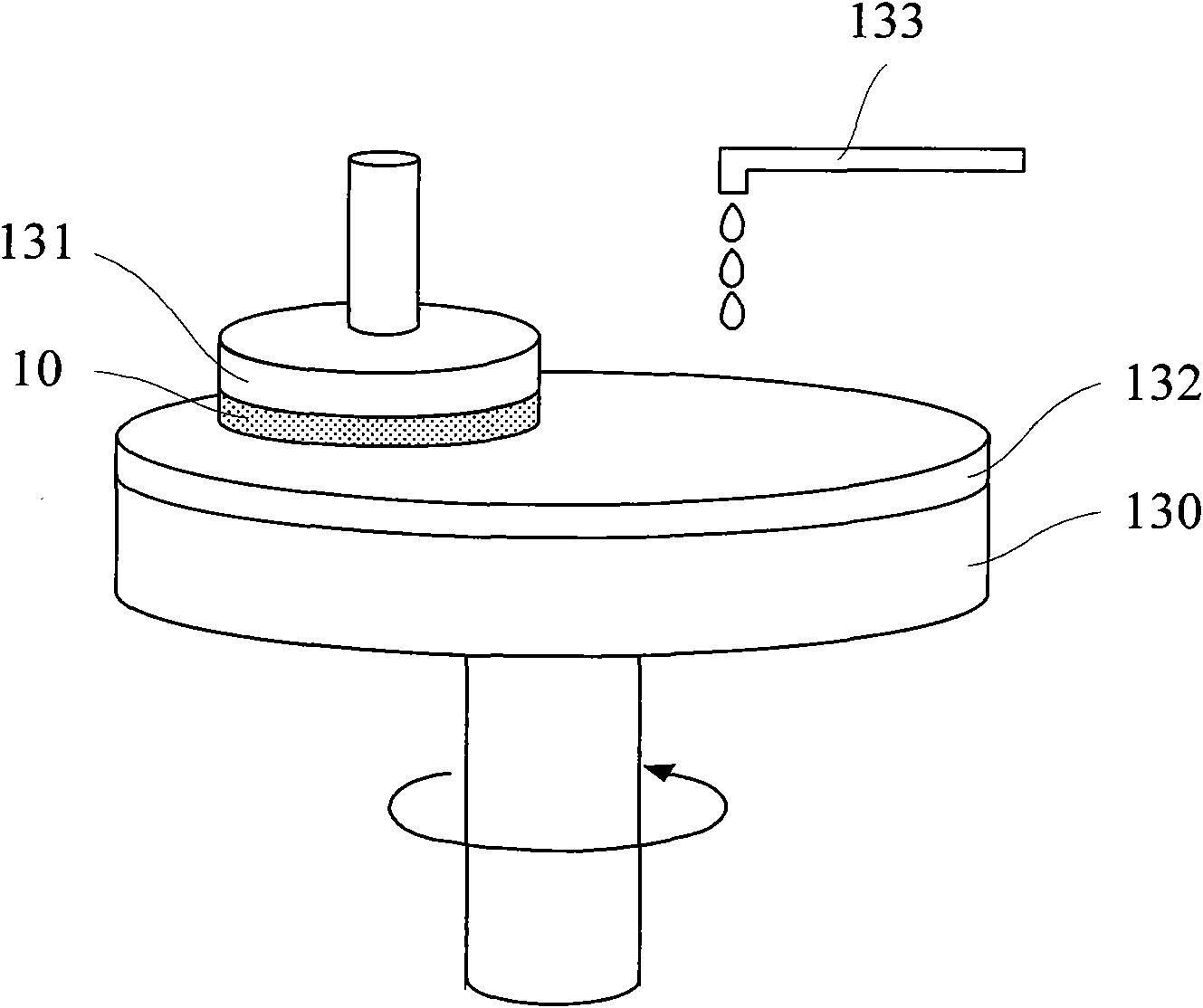

[0028]According to the description of the background technology, in the existing chemical mechanical polishing rework method, when the first wafer on the third grinding platform is subjected to grinding treatment, the second wafer and the second wafer waiting on the second grinding platform and the first grinding platform are not processed. Any isolation process for the three wafers makes it very likely that various pollutants on the chemical mechanical polishing platform will splash onto the surface of the second wafer and the third wafer, thereby contaminating the second wafer and the third wafer, resulting in a decrease in the yield of semiconductor devices. Therefore, the present invention provides a kind of rework method of chemical mechanical polishing process, when this method sprays polishing fluid to the surface of the first wafer on the third grinding platform to remove the defect of the first wafer surface, also wait on the second grinding platform. The surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com