Numerical-control pipe bead embroidery machine

A technology of car embossing and pipe beading, which is applied in the direction of turning equipment, turning equipment, metal processing equipment, etc., and can solve the problems of low production efficiency of manual operation, insufficient appearance and standardization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

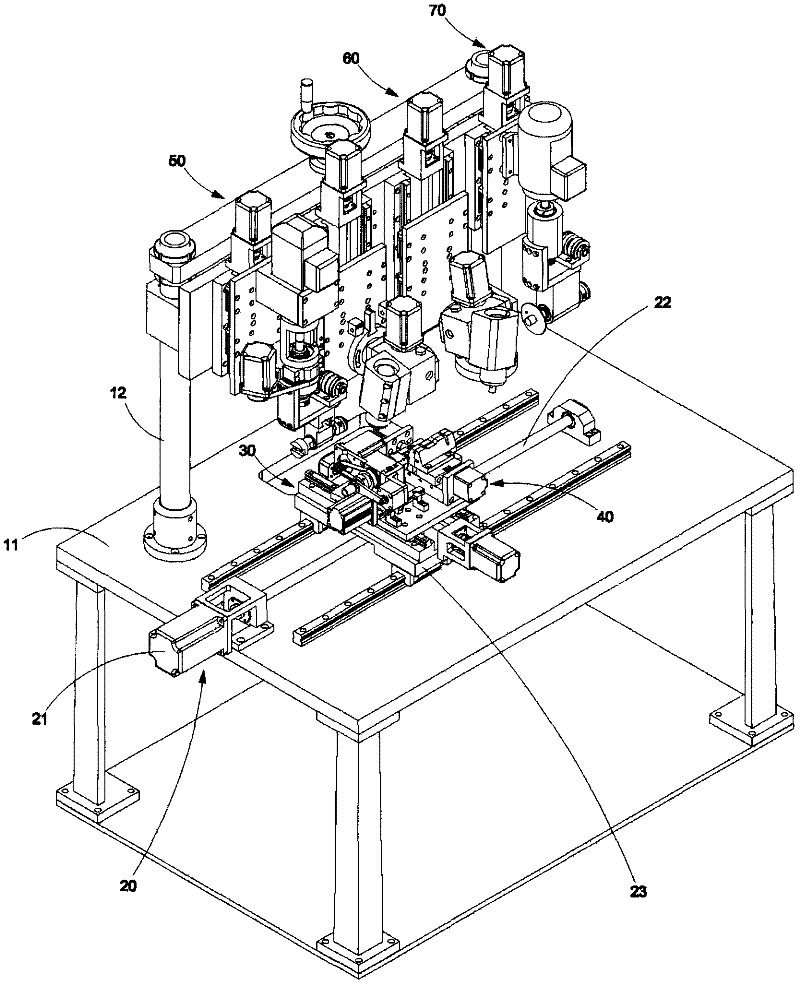

[0026] Such as Figure 1 to Figure 5 Shown is a kind of preferred concrete implementation example of the present invention, a kind of numerically controlled tube bead car flower machine, such as figure 1 Shown include

[0027] A frame 10, wherein the frame 10 includes a workbench 11 and a mounting frame 12, and the mounting frame 12 is fixedly arranged on one side of the table top of the workbench 10;

[0028] A moving device 20, the moving device 20 includes a stepping motor 21, a ball screw pair 22 connected to the stepping motor 21 and a moving table 23 connected to the nut of the ball screw pair 22;

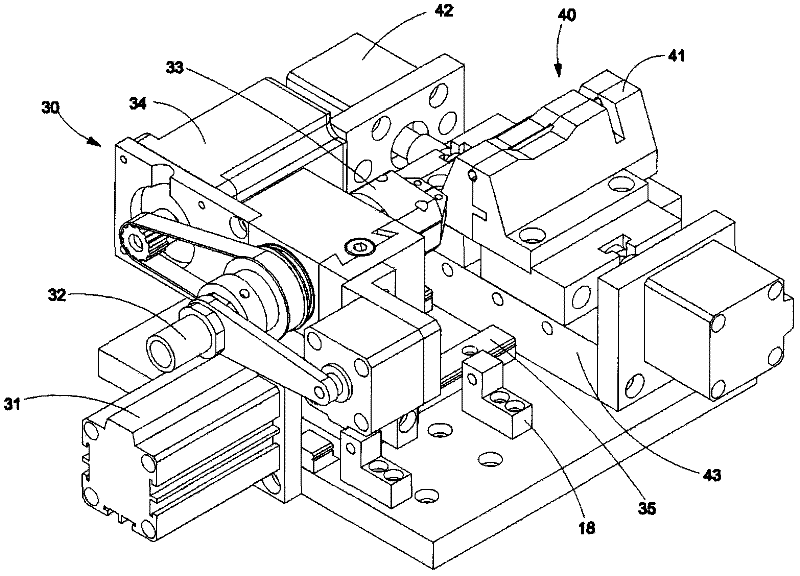

[0029] An automatic material pushing device 30, the automatic material pushing device 30 is installed on the mobile platform 23,

[0030] An automatic material clamping device 40, the automatic material clamping device 40 is installed on the mobile platform 23 in cooperation with the automatic material pushing device 30;

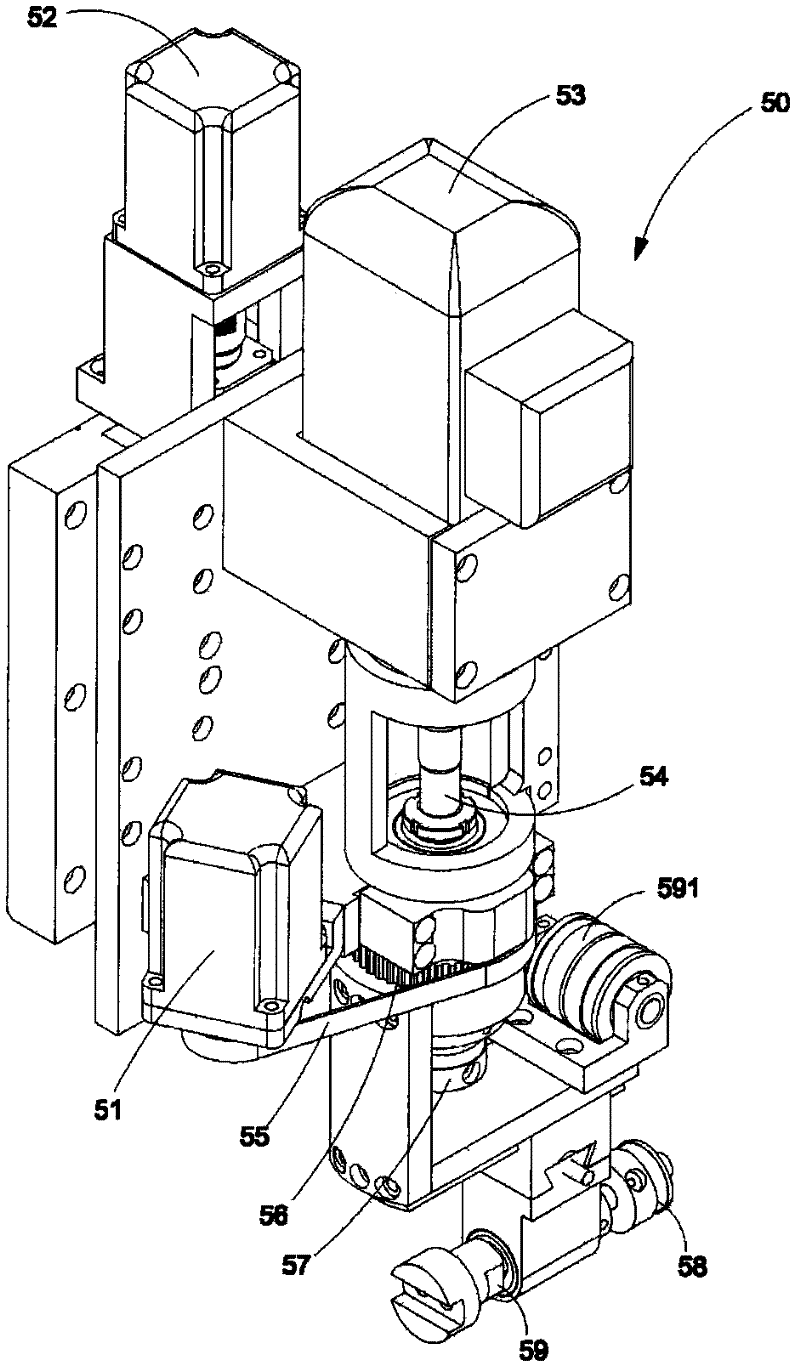

[0031] A pattern equal parts automatic rotation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com