Coating System And Coating Method Using The Coating System

A coating method and coating technology, applied in the field of coating systems, can solve the problem of excessive coating waste, and achieve the effects of reducing waste, restraining the increase of air-conditioning energy, and restraining large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

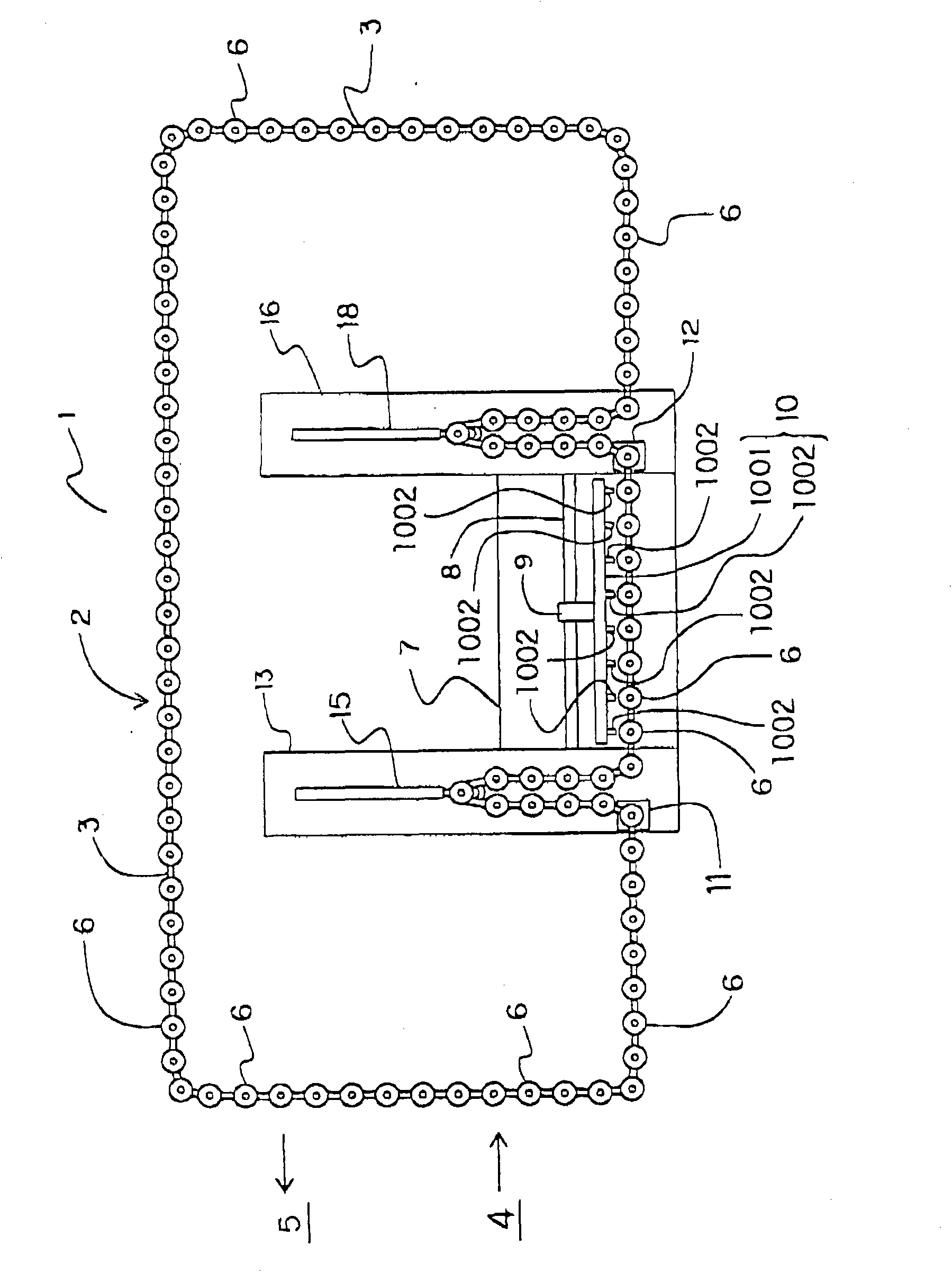

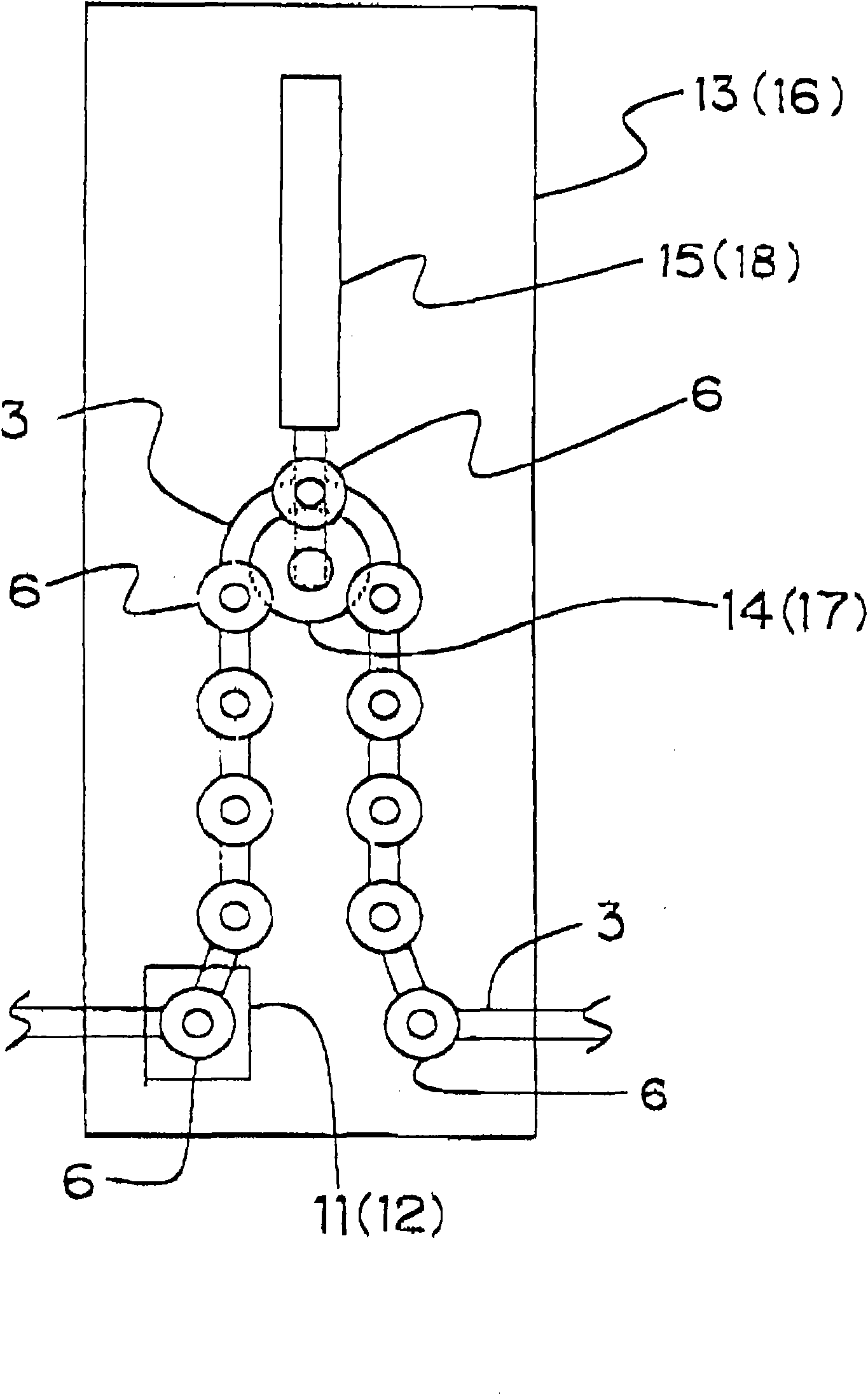

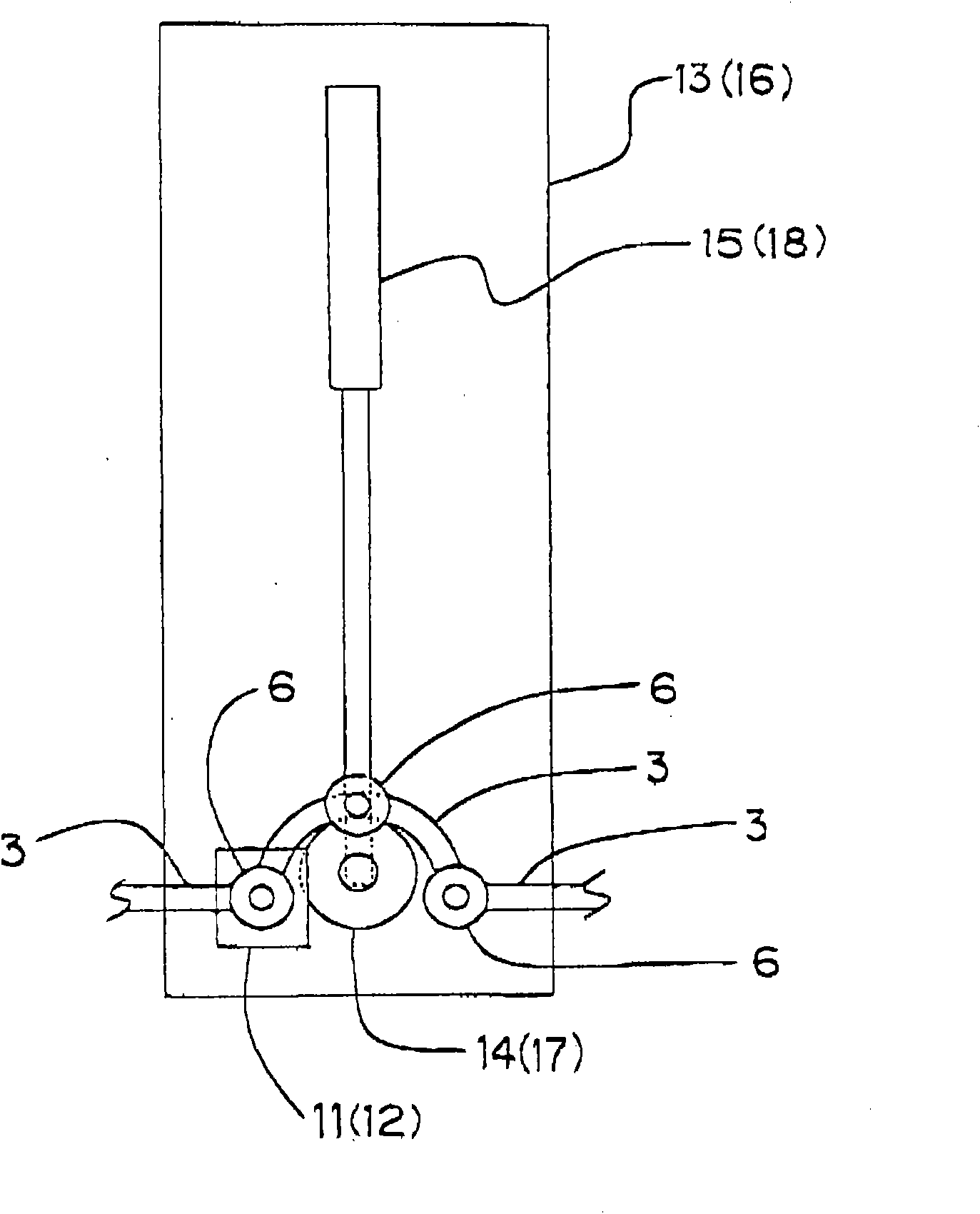

[0081] Embodiments of the painting system of the present invention are described below with reference to the accompanying drawings, figure 1 It is a view for explaining the overall structure of the embodiment of the painting system of the present invention. In the figure 1 is the painting system of this embodiment, and in the painting system of this embodiment, it is the frame as a painting mobile phone coating system. However, the painting object of the present invention is not limited to the frame body of the mobile phone, but can be any object.

[0082] Furthermore, in the coating system 1 of this embodiment, the conveying line for conveying a workpiece is provided, and this conveying line is comprised by the chain conveyor. That is, 2 in the figure is a transmission line, and 3 in the figure is a chain conveyor belt, and the chain conveyor belt 3 is an endless chain.

[0083] In addition, 6 in the figure is a workpiece supply workbench. In the coating system 1 of this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com