Flux composition for lead-free solder, and lead-free solder composition

A lead-free solder and composition technology, applied in the preparation of organic compounds, welding/cutting media/materials, soldering media, etc., can solve problems such as complex fixing processes, and achieve suppression of void generation, prevention of curing inhibition, and excellent wetting sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

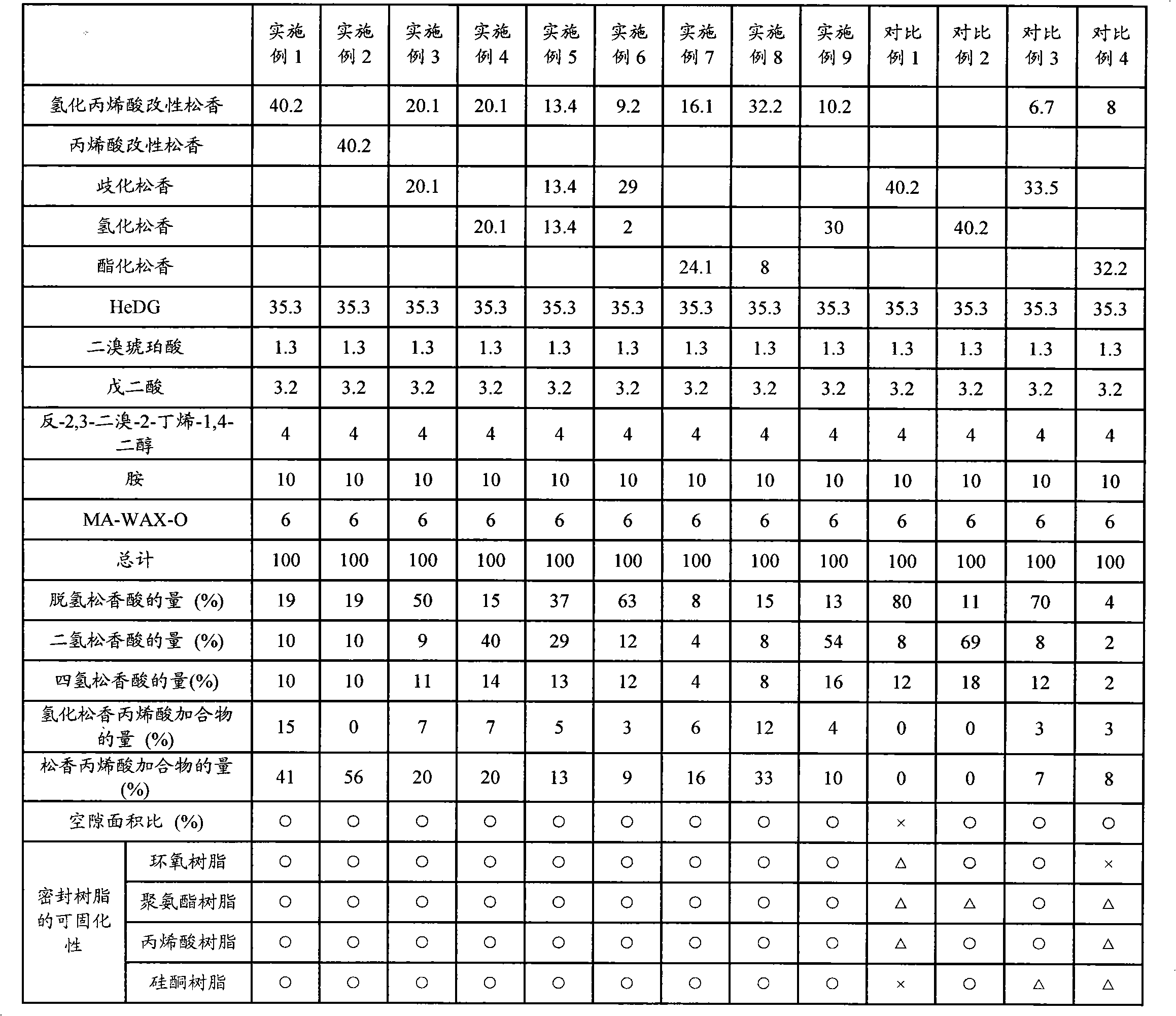

Examples

Embodiment 1

[0066]A flux composition for cream solder was prepared by mixing the following components: 40.2% by weight of hydrogenated acrylic acid-modified rosin (manufactured by Arakawa Chemical Industry Co., Ltd.); composition: 19% by weight of dehydroabietic acid, 10% by weight of dihydroabietic acid, 10 wt% tetrahydroabietic acid, 15 wt% hydrogenated rosin acrylic acid adduct and rosin acrylic acid adduct 41 wt%, 1.3 wt% dibromosuccinic acid (manufactured by Aldrich), 3.2 wt% glutaric acid (Tokyo Chemical Co., Ltd.), 4 wt% trans-2,3-dibromo-2-butene-1,4-diol (Tokyo Chemical Co., Ltd.), 10 wt% amine (Lion Akzo Co. , Ltd.), 35.3 wt% of diethylene glycol monohexyl ether (manufactured by Nippon Emulsifier Co., Ltd.), and 6 wt% of thixotropic agent (MA-WAX-O (manufactured by Kawaken Fine Chemical Co., Ltd.)) .

[0067] The flux composition thus obtained was used together with a solder alloy comprising 96.5 wt% Sn, 3.0 wt% Ag and 0.5 wt% copper to prepare a cream solder having a particle ...

Embodiment 2

[0069] Solder cream was obtained in the same manner as in Example 1, except that acrylic acid-modified rosin (manufactured by Arakawa Chemical Industry Co., Ltd.); composition: 19 wt % of dehydroabietic acid, 10 wt % of dihydroabietic acid, 10 wt % % tetrahydroabietic acid and 56wt% rosin acrylic acid adduct) to replace hydrogenated acrylic acid modified rosin (Arakawa Chemical Industry Co., Ltd.); composition: 19wt% dehydroabietic acid, 10wt% dihydroabietic acid, 10wt% % tetrahydroabietic acid, 15 wt% hydrogenated rosin acrylic acid adduct and 41 wt% rosin acrylic acid adduct) were used as rosin derivation components.

Embodiment 3

[0071] Solder cream was obtained in the same manner as in Example 1, except that the same hydrogenated acrylic acid-modified rosin and dehydroabietic acid-rich disproportionated rosin (manufactured by Arakawa Chemical Industry Co., Ltd.; composition: 80 wt% of dehydroabietic acid, 8 wt% of dihydroabietic acid, and 12 wt% of tetrahydroabietic acid; hereinafter referred to as "disproportionated rosin") each replaced 40.2 wt% of hydrogenated acrylic acid-modified rosin in an amount of 20.1 wt%. Arakawa Chemical Industry Co., Ltd.; composition: 19 wt% of dehydroabietic acid, 10 wt% of dihydroabietic acid, 10 wt% of tetrahydroabietic acid, 15 wt% of hydrogenated rosin acrylic acid adduct, and 41 wt% of rosin acrylic acid adduct compounds) are used as rosin-derived components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com