Support structure for large-span continuous beam construction

A support structure and long-span technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of slow construction speed and impact on construction period, and achieve the effect of low cost, reasonable quantity and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

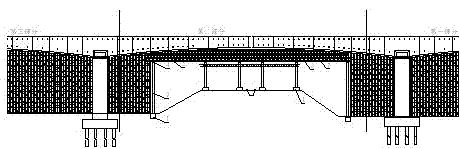

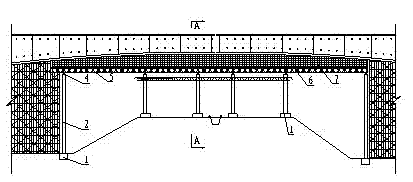

[0015] Embodiments of the present invention: as figure 1 "Part Two" in and figure 2 As shown, the cross-highway section adopts a combined structure of steel pipe brackets and bowl buckle-type full hall brackets 7, the lower part adopts a strip foundation 1, the top of the strip foundation 1 is a steel pipe column 2, and the top of the steel pipe column 2 is a double I40 I-shaped The load-bearing beam 4 that steel is made, is Bailey beam 5 above the load-bearing beam 4, and the I-beam 6 of I16 is arranged above the Bailey beam 5, and the I-beam 6 is a bowl buckle type full hall support 7 above the I-beam 6.

[0016] Such as figure 1 "Part One", "Part Three" and Figure 4 , Figure 5 As shown, all adopt the bowl button type full hall support 7 outside the highway range.

[0017] The steel pipe support is composed of steel pipe columns 2 and vertical and horizontal connecting rod systems 3 .

[0018] Vertical and horizontal connecting rod systems 3 are arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com