Method for preparing methane by pretreating asparagus straws with NaOH

A technology for pretreatment and asparagus, which is applied in the field of biomass energy utilization, can solve problems such as undiscovered reports, and achieve the effects of improving biological digestibility, accelerating degradation, and making the process simple and easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

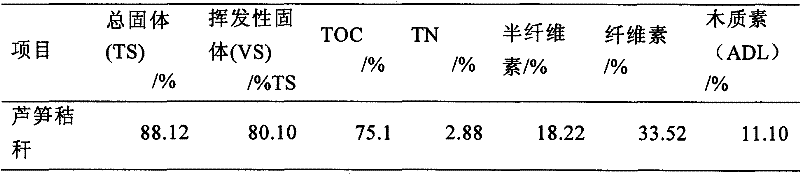

Image

Examples

Embodiment 1

[0038] Using the asparagus stalks obtained in step ②, add NaOH solution with the same mass as the asparagus stalks and a concentration of 6%, the pretreatment time is 20 days, and the fermentation time is 25 days. The pretreatment temperature is 25±1°C; the biogas fermentation temperature is 35±1°C, the total volume of the fermentation broth is 800mL, the ratio of inoculation sludge to the mass of all reaction materials is 30%, and the total solid content of the fermentation broth is 6%.

[0039] The contents of cellulose, hemicellulose and lignin after NaOH pretreatment and biogas fermentation of asparagus straw were as follows (mass fraction):

[0040] Table 3 Changes of cellulose, hemicellulose and lignin content after asparagus straw pretreatment and biogas fermentation

[0041]

[0042] The total gas production in 25 days of biogas fermentation is 10754mL, CH 4 The daily maximum content is 63.91%.

Embodiment 2

[0044] Using the asparagus stalks obtained in step ②, add NaOH solution with the same mass as the asparagus stalks and a concentration of 6%, the pretreatment time is 15 days, and the fermentation time is 25 days. The pretreatment temperature is 25±1°C; the biogas fermentation temperature is 35±1°C, the total volume of the fermentation broth is 800mL, the ratio of inoculation sludge to the mass of all reaction materials is 30%, and the total solid content of the fermentation broth is 6%.

[0045] The contents of cellulose, hemicellulose and lignin after NaOH pretreatment and biogas fermentation of asparagus straw were as follows (mass fraction):

[0046] Table 4 Changes of cellulose, hemicellulose and lignin content after asparagus straw pretreatment and biogas fermentation

[0047]

[0048] The total gas production of 25 days of biogas fermentation is 9461mL, CH 4 The daily maximum content is 60.73%.

Embodiment 3

[0050] Using the asparagus stalks obtained in step ②, add NaOH solution with the same mass as the asparagus stalks and a concentration of 5%, the pretreatment time is 20 days, and the fermentation time is 30 days. The pretreatment temperature is 25±1°C, the biogas fermentation temperature is 35±1°C, the total volume of fermentation broth is 800mL, the ratio of inoculated sludge to the mass of all reaction materials is 30%, and the total solid content of fermentation broth is 6%.

[0051] The contents of cellulose, hemicellulose and lignin after NaOH pretreatment and biogas fermentation of asparagus straw were as follows (mass fraction):

[0052] Table 5 Changes of cellulose, hemicellulose and lignin content after asparagus straw pretreatment and biogas fermentation

[0053]

[0054] The total gas production in 25 days of biogas fermentation is 12833mL, CH 4 The daily maximum content is 64.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com