Shell and manufacturing method thereof

A manufacturing method and housing technology, which can be used in chemical instruments and methods, electrical equipment housings/cabinets/drawers, electrical components, etc., and can solve problems such as ink shrinkage and adverse effects on the appearance of the housing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

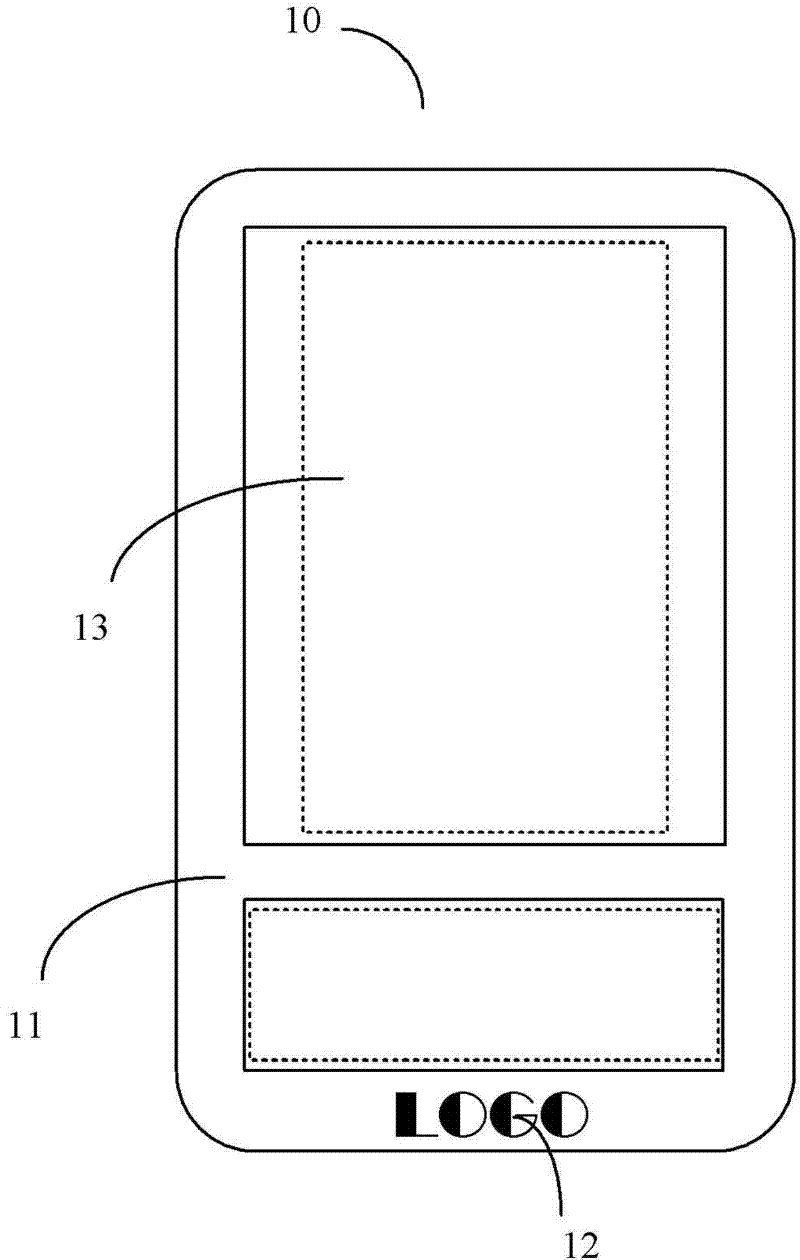

[0030] see figure 1 , which discloses a portable electronic device 10 according to an embodiment of the present invention. The electronic device 10 may be a digital photo frame, an e-book reader, or an MP3 player. The electronic device 10 includes a casing 11 and a display area 13 .

[0031] Please also refer to figure 2 , the housing 11 includes a plastic substrate layer 110 and a pattern layer 12 formed on the plastic substrate layer 110 . In the first embodiment, the pattern layer 12 sequentially includes an adhesive layer 111 , a metal coating layer 112 and a transparent protection layer 113 .

[0032] In this embodiment, the transparent protective layer 113 is a layer of transparent plastic film with a thickness between 0.1 mm and 0.5 mm. The material of the transparent protective layer 113 may be polyethylene terephthalate, polycarbonate or polymethyl methacrylate.

[0033] The metal coating layer 112 is sputter deposited on one surface of the transparent protectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com