Design analysis method for gas turbine gas inlet device

A technology of air intake device and design analysis, applied in calculation, special data processing applications, instruments, etc., can solve problems such as huge workload, correctness and error of conclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A design and analysis method for a gas turbine intake device, comprising the steps of:

[0049] Step 1: Build a model;

[0050] First, carry out the preliminary design of the 2D view, and after determining the size of each part of the 2D view, perform ANSYS 3D modeling on the parts that need to be calculated and analyzed;

[0051] According to the specific technical requirements of the analysis object, the accuracy requirements of analysis and calculation, etc., the finite element division of the analysis object is carried out, so that the computer can use sufficient resources to analyze and calculate each unit;

[0052] Structural analysis and working process:

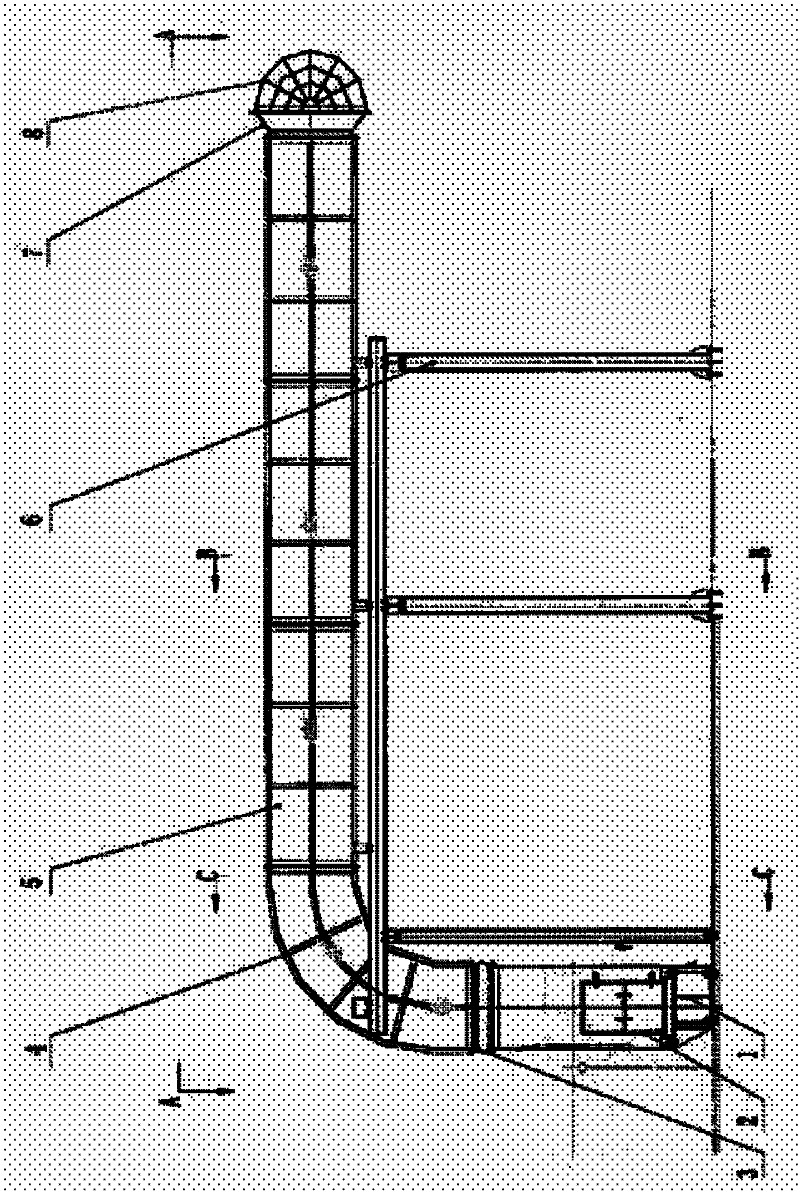

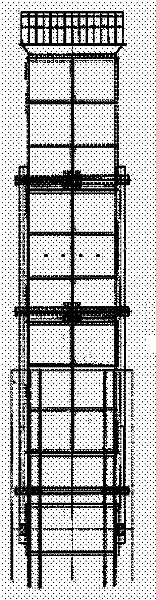

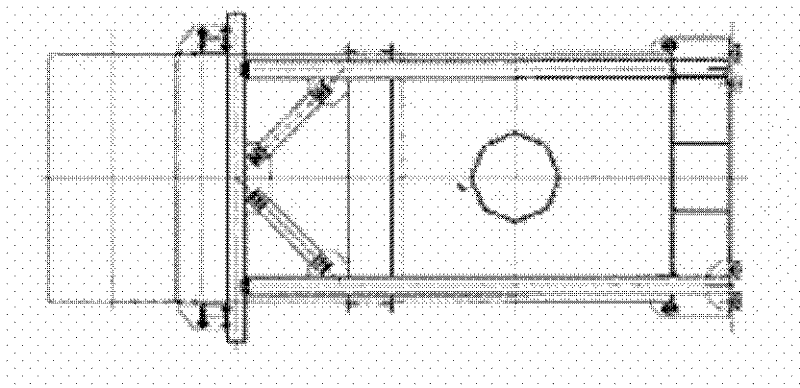

[0053] The gas turbine test bench air intake device includes: intake filter cover, intake shroud, intake straight section, intake elbow, interface soft connection, intake volute, intake volute base and structural steel frame, etc., such as Figure 1 ~ Figure 4 shown.

[0054] The air passes through the intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com