Electromagnetic load reduction bearing for hydraulic generator

A technology for hydroelectric generators and bearings, which is applied to bearings, shafts, bearings, mechanical equipment, etc. It can solve the problems of coil insulation performance degradation, high processing and maintenance costs, and high bearing precision requirements, and achieve the effect of no lubrication life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

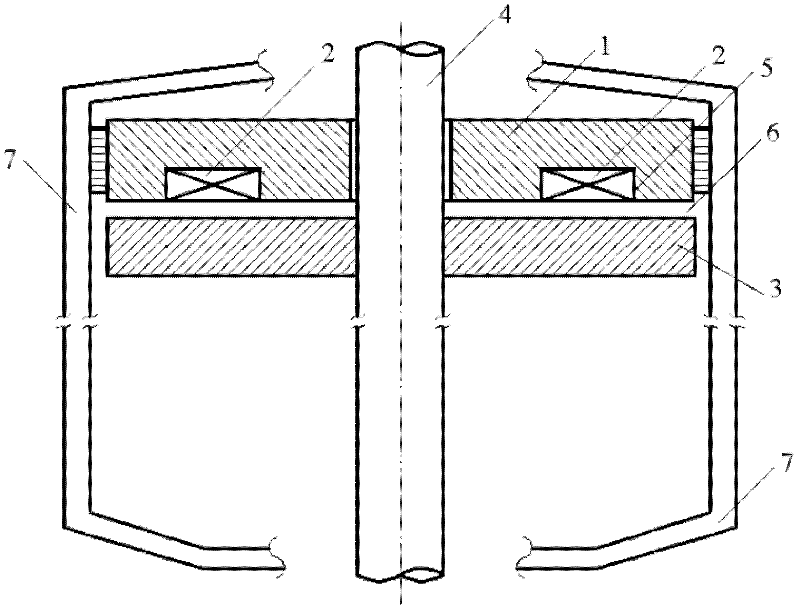

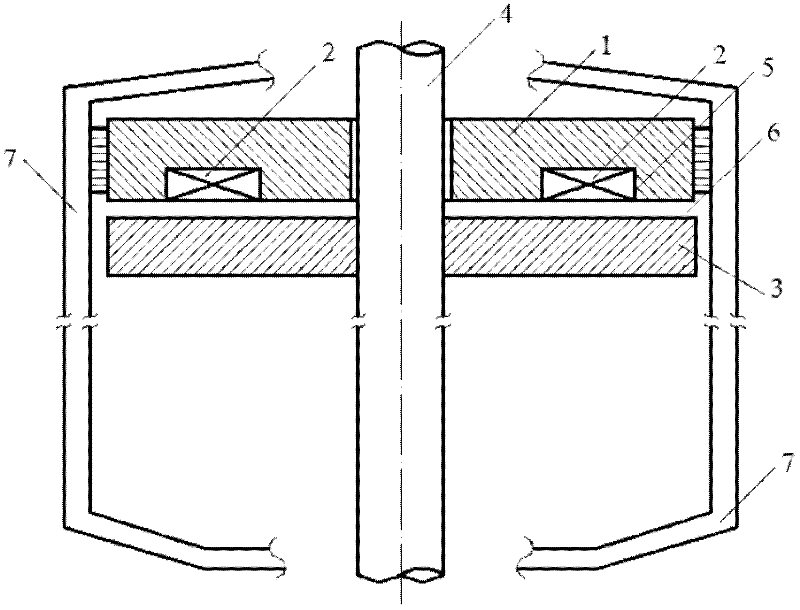

[0009] Such as figure 1 As shown, the electromagnet is fixed on the motor stator 7 and consists of a ferromagnetic material iron core 1 and a coil 2, and the coil 2 is embedded in a groove 5 of the ferromagnetic material iron core to form an electromagnet. Thrust disc 3 is made of ferromagnetic material and is fixed on motor rotor 4 . The gap 6 between the electromagnet and the thrust disc can be set according to specific requirements. According to different motor rotor load reduction requirements, the suction force between the electromagnet and the thrust disc can be adjusted by adjusting the current in the electromagnet coil 2 through the control system.

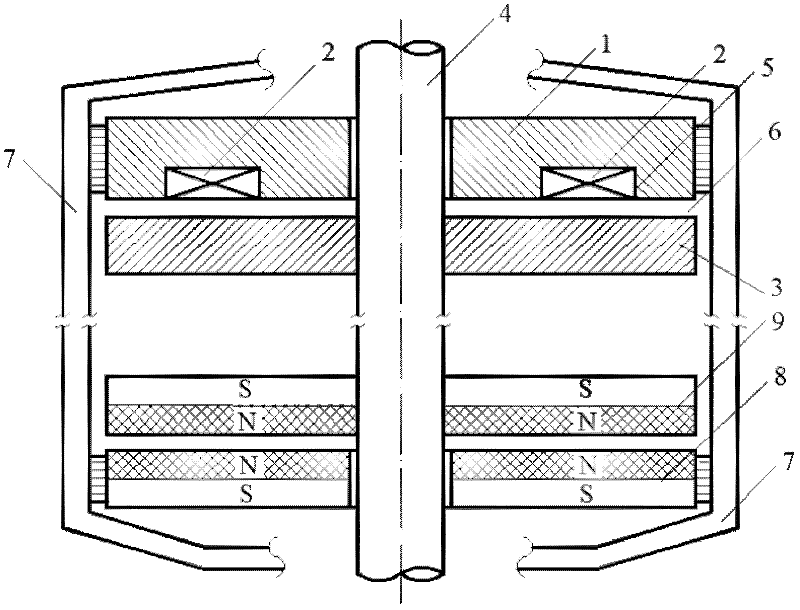

[0010] The load-reducing bearing can be installed and used in multiple positions in the hydro-generator, and the electromagnetic bearing can also be made into various structures. For example, the load-reducing bearing can be additionally provided with permanent magnets arranged opposite to each other with the same pole be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com