Waste chamotte brick regeneration and utilization method, and concrete doped with waste chamotte brick powder

A technology for waste clay brick powder and concrete, which is applied to the concrete mixed with recycled waste clay brick powder and the recycling field of waste clay bricks, can solve the problem of large amount of cement, and can reduce the treatment cost, cost, landfill and waste. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation and testing methods of recycled clay brick concrete are the same as those of ordinary concrete, and are completely in accordance with GB / T 50081-2002 "Standards for Test Methods of Mechanical Properties of Ordinary Concrete" and GB / T50082-2009 "Test Methods for Long-term Performance and Durability of Ordinary Concrete ".

[0048] 4. Experimental results

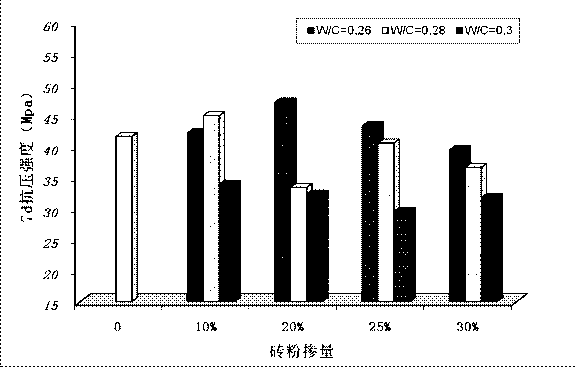

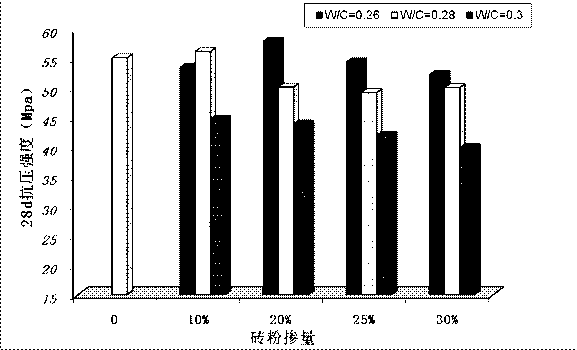

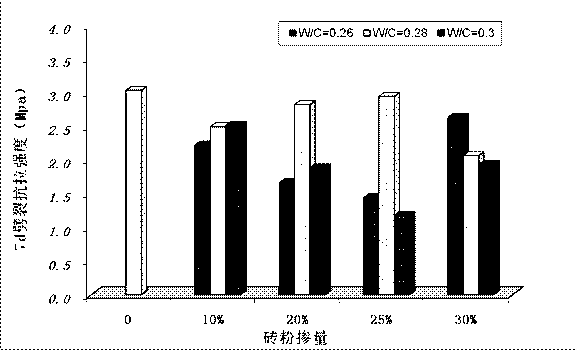

[0049] Figure 1 to Figure 4 It is the mechanical performance test data of recycled waste clay brick concrete. The abscissa is the replacement rate of brick powder, and the performance of recycled concrete is the vertical axis to draw a column graph. It can be seen from the figure that with the increase of clay brick content and the decrease of cement content, the mechanical properties of concrete such as compressive resistance and flexural resistance decrease, especially the mechanical properties in the early stage decrease significantly. However, with the increase of time, the performance of concr...

Embodiment 1

[0053] The waste clay bricks are crushed to a particle size of 0.04mm, and recycled and reused. The method is as follows: using waste clay brick powder to partially replace cement as a cementitious material to prepare concrete. The ratio of raw materials for the concrete is: the addition of clay brick powder is 0-30%, the mass ratio of cementitious material (cement + brick powder) to aggregate is 1:3.6, the sand rate is 35%, water ash The ratio is 0.30, and the water reducer is a polycarboxylate ether water reducer. All polycarboxylate ether water reducers sold on the market can be used in the present invention, and the dosage is 1% of the mass of the gelling material. The concrete was prepared according to the general method, and the 28d compressive strength of the obtained concrete was 42~48MPa.

Embodiment 2

[0055] The waste clay bricks are crushed to a particle size of 0.06 mm, and recycled and reused. The method is as follows: using waste clay brick powder to partially replace cement as a cementitious material to prepare concrete. The ratio of raw materials for the concrete is: the addition of clay brick powder is 0-30%, the mass ratio of cementitious material (cement + brick powder) to aggregate is 1:3.5, the sand rate is 33%, water ash The ratio is 0.28, and the water reducer is polycarboxylate ether water reducer. All polycarboxylate ether water reducers sold in the market can be used in the present invention, and the dosage is 1.2% of the mass of the gelling material. The concrete was prepared according to the general method, and the 28d compressive strength of the obtained concrete was 49~56MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com