Oven illumination and oven

A lighting and stove technology, applied in oven lighting, lighting and heating equipment, household lighting, etc., can solve the problems of frequent replacement of light sources, limited life of light sources, small volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

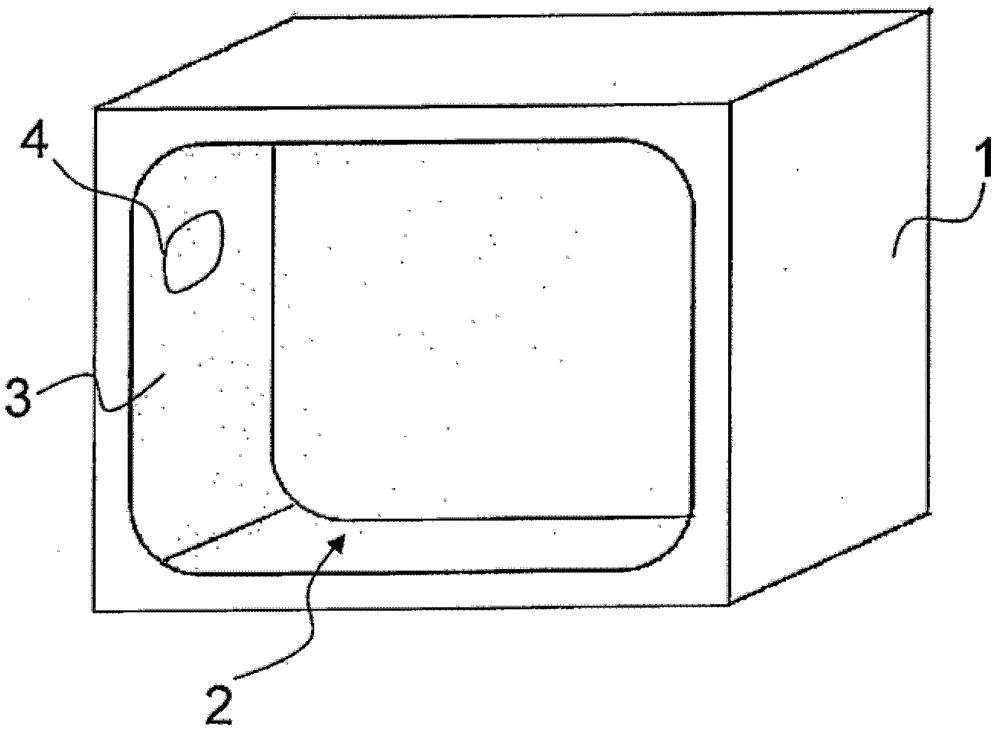

[0033] figure 1 A chamber 1 of a baking oven for domestic appliances is shown schematically. The muffle body 1 has side walls, a top wall and a rear wall defining a baking chamber 2 . The muzzle 1 has a front opening 3 for placing food to be baked (not shown) in and out of the baking chamber 2 .

[0034] Typically, a door (not shown) is provided for tightly closing the front opening 3 during baking. Normally, the door has a transparent glass portion. This glass portion is used for visual inspection and control by the user of the food product placed in the chamber 1 . This inspection is preferably performed without opening the door.

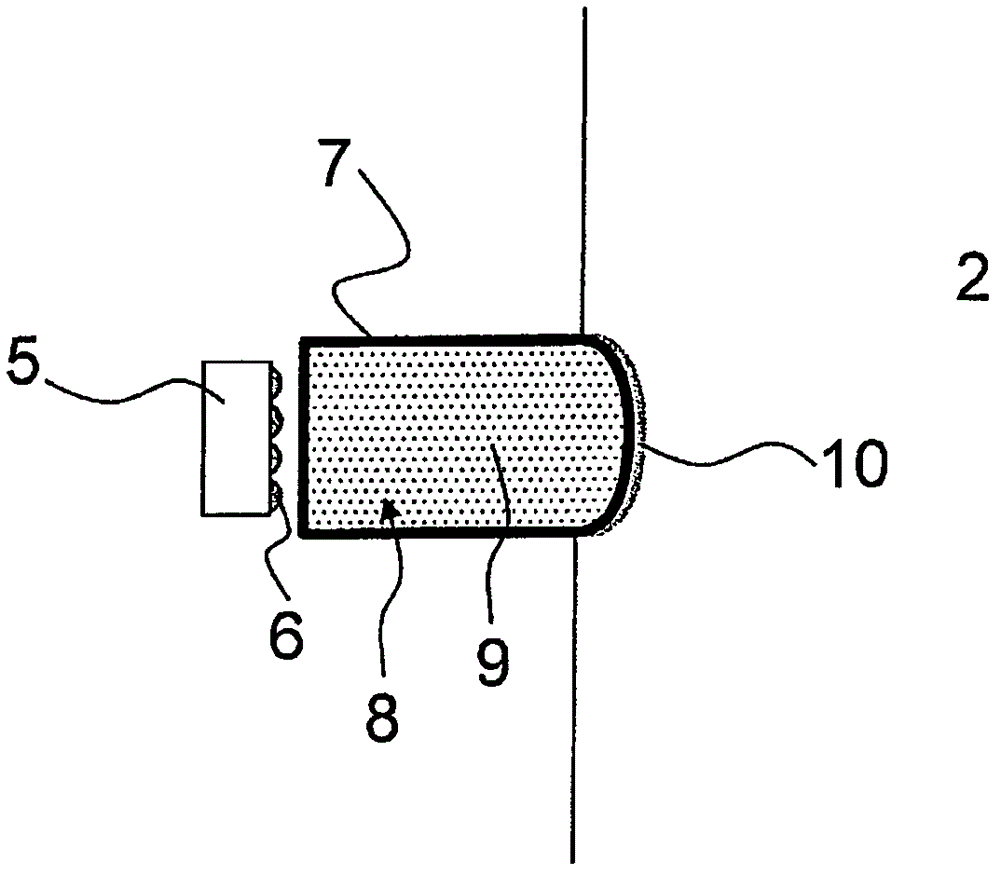

[0035] Since the muffle 1 of a baking oven is normally dark when the door is closed and viewed from the outside, the oven illuminators 4 for illuminating the inside of the muffle 1 are used to allow visual inspection during the baking process. The furnace lighting 4 is placed in a recess provided in the side wall of the muffle 1 . The positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com