Mould seat for compressing cable conductor

A technology of cable conductors and mold holders, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of lower installation efficiency, conductor asymmetry, inconvenient installation and use, etc., and achieve good quality cable conductors and tight conductors Symmetrical and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

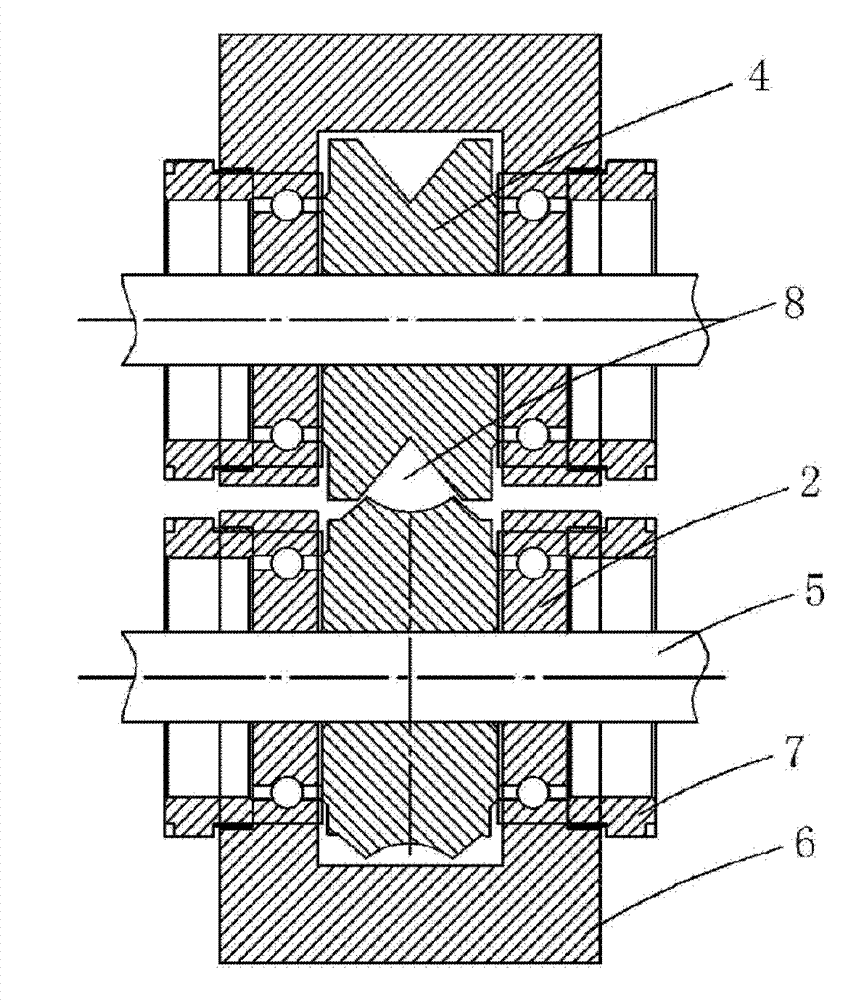

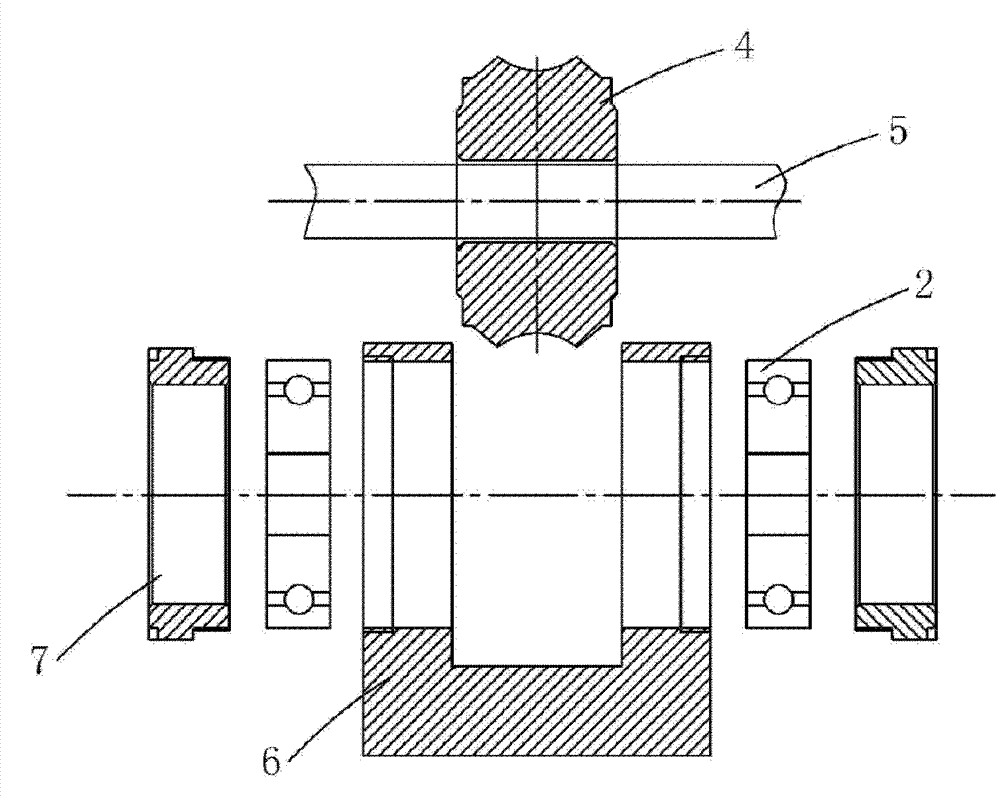

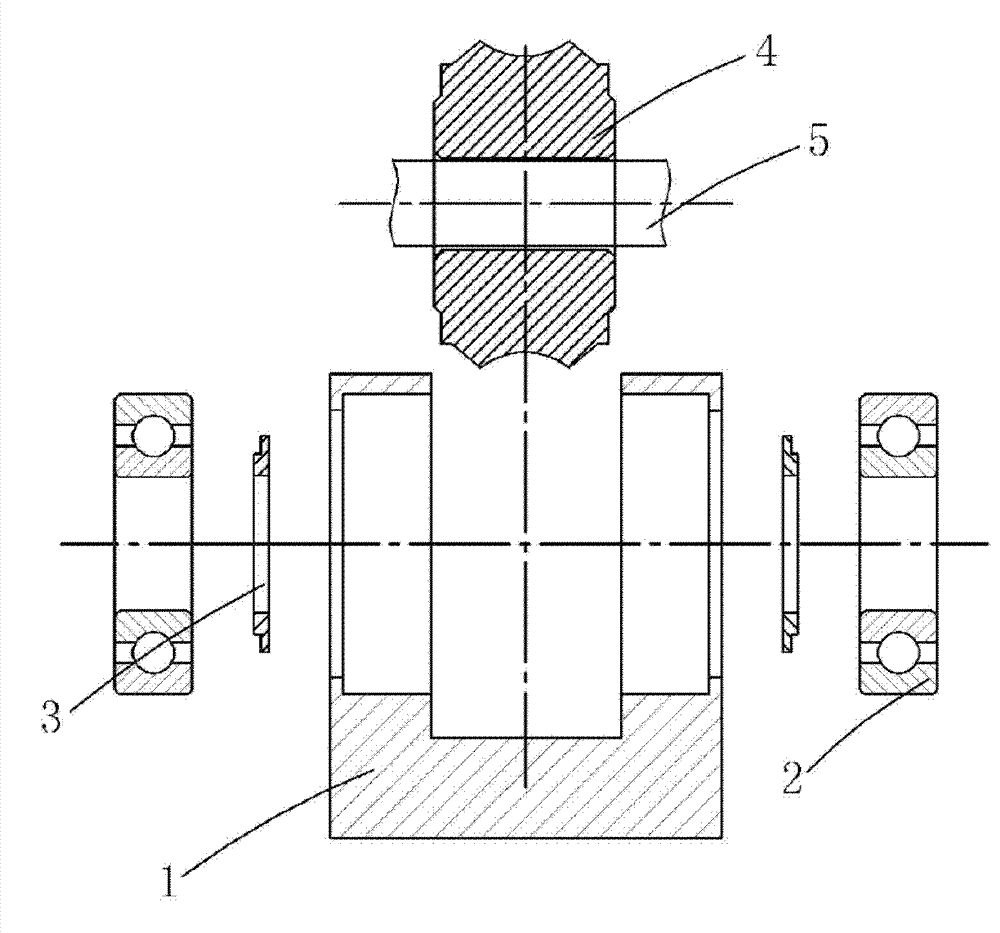

[0018] Example: see figure 1 , 2 , the mold seat for tight pressing of the cable conductor in this embodiment is composed of two up and down symmetrical roller seats, and each roller seat includes:

[0019] A U-shaped base 6 is provided with a compression mold 4 in the inner cavity of the base 6, bearings 2 are respectively provided in the side wall holes on both sides of the base, and a circular cover 7 is respectively provided at the outer end of each bearing , the outer circumference of each circular cover is threadedly connected to the side wall of the base 6, two circular covers 7, two bearings 2 and a compression mold 4 are coaxially arranged and share the mandrel 5; two pressure roller seats The openings of the U-shaped base 6 are opposite, and the opposite cylindrical surfaces of the two pressing dies 4 form a combined working part 8 for pressing the cable conductor.

[0020] The present invention is provided with the circular hole that has internal screw thread on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com