Method for optimally designing structure of sliding shaft sleeve based on Kriging model

An optimized design, sliding shaft technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as excessive stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

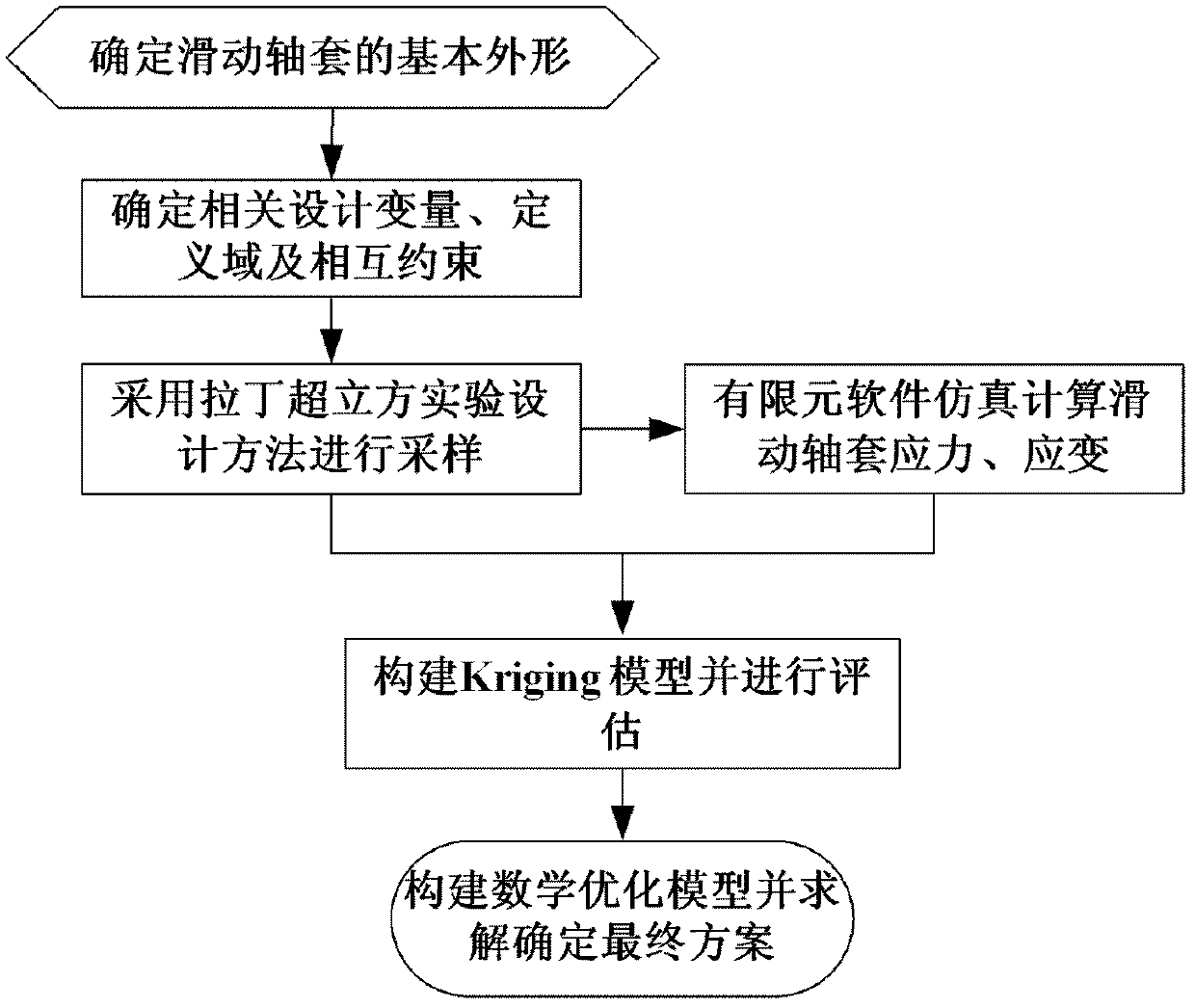

[0045] The sliding bushing structure optimization design method based on the Kriging model provided by the present invention, such as figure 1 As shown, the steps include:

[0046] 1. Determine the basic shape and preliminary dimensions of the sliding bushing;

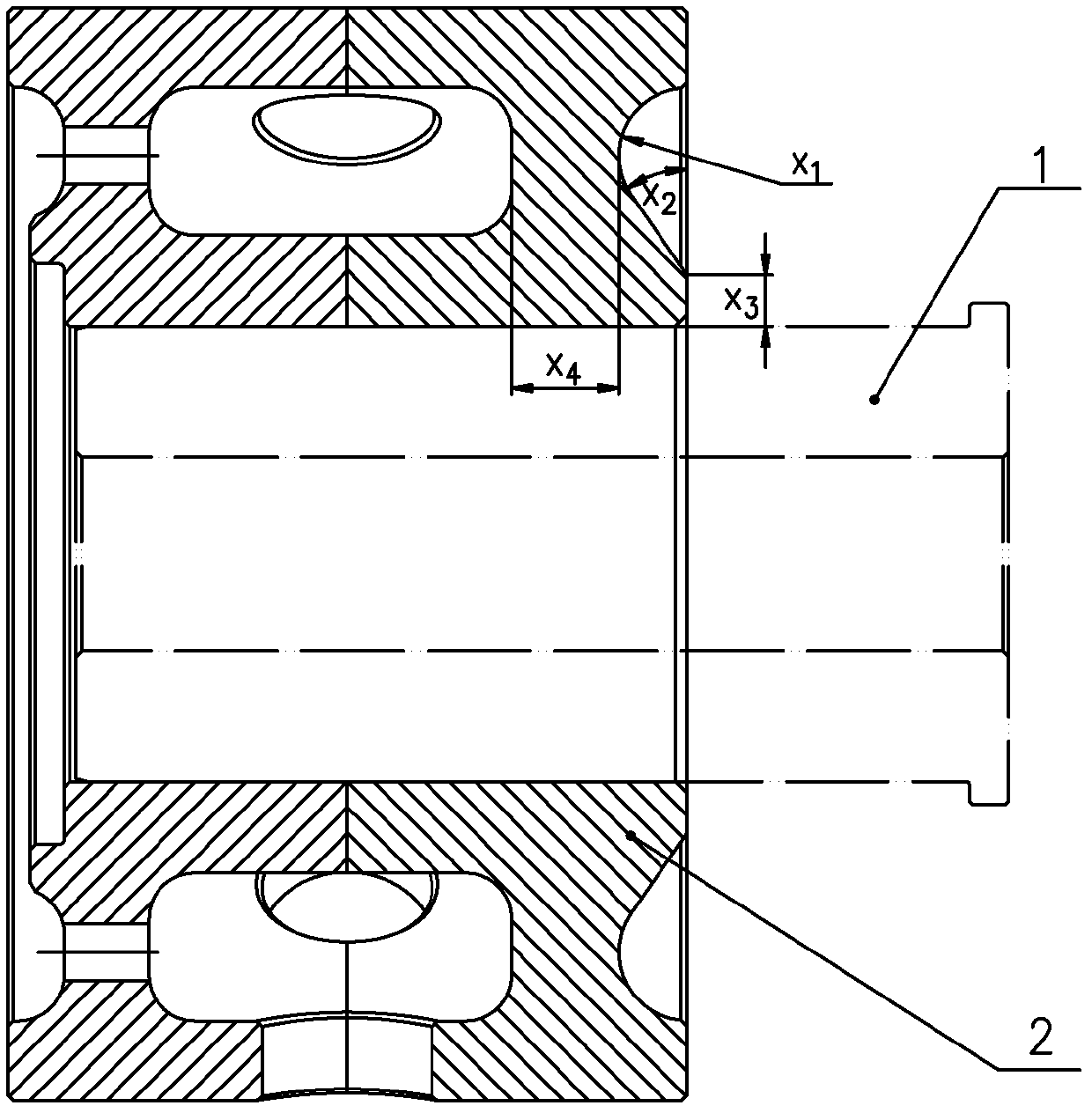

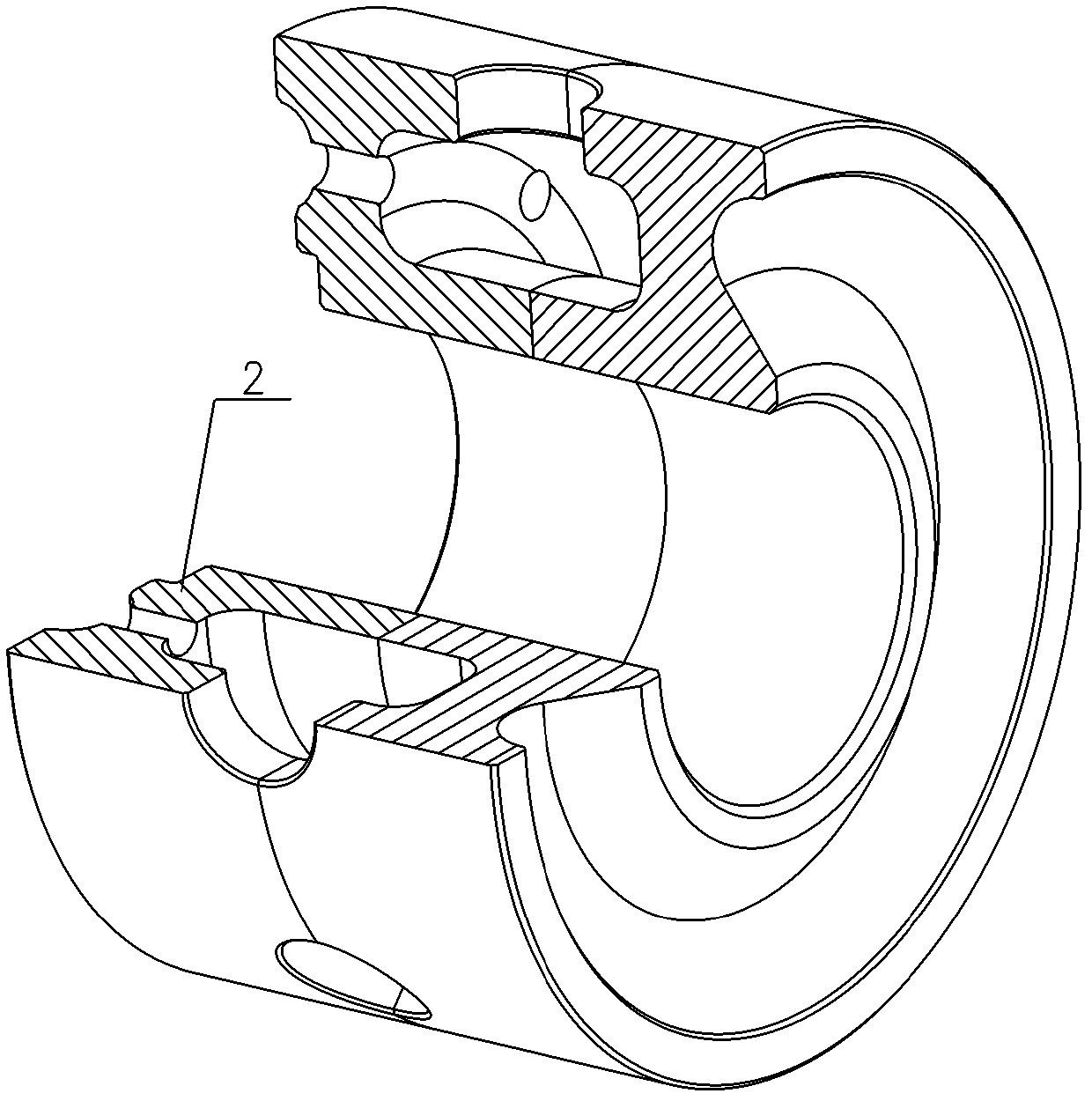

[0047] The connection device of the spherical hinge sliding rod type converter support ring and the furnace shell transfers the weight of the entire converter shaft to the converter support ring through three connection devices, and for each connection device, the load acts on the sliding shaft through the support shaft. Therefore, the structural design of the sliding sleeve will affect the stress of the entire connecting device, and its structural design is extremely important. The fixed ball hinge bearing on the support shaft is subject to 3.5×10 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com