Anchor of warp knitting machine

A warp knitting machine and ground foot technology is applied in the field of ground foot in textile machinery such as warp knitting machine or other processing equipment, which can solve the problems of poor shock absorption effect and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

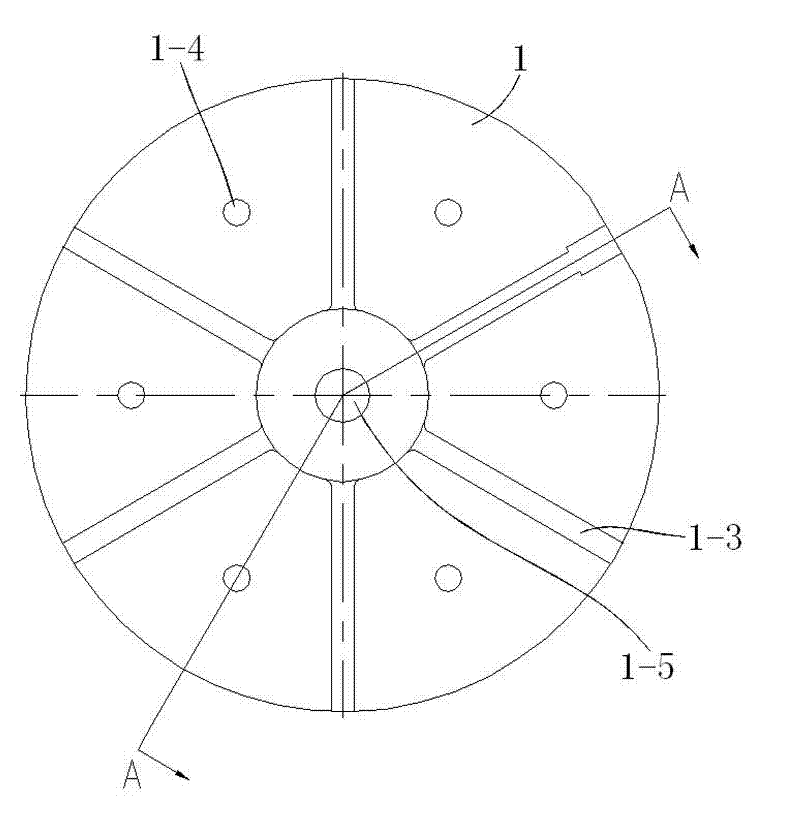

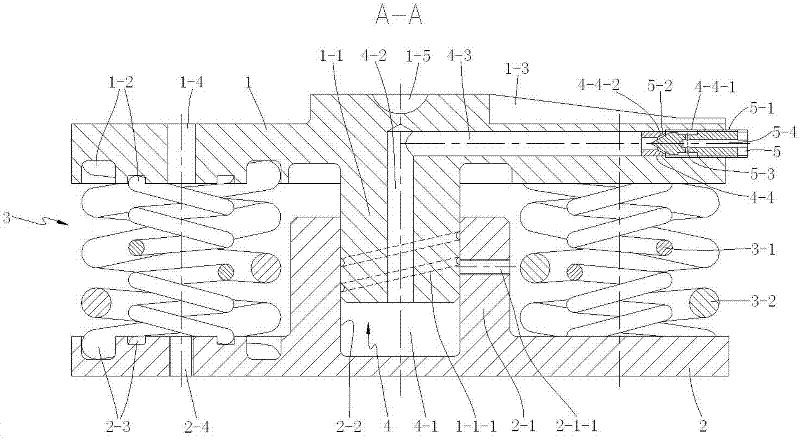

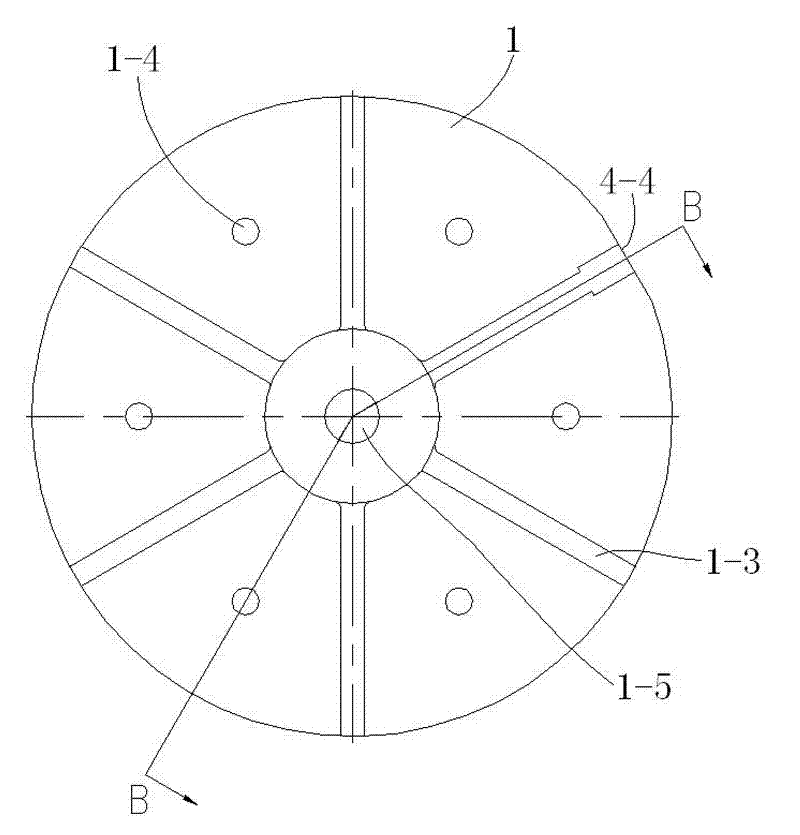

[0022] As a preferred embodiment of the present invention, the cross-sections of the upper and lower support plates 1 and 2 are circular, the first shaft part 1-1 is cylindrical, and the second shaft part 2-1 There is a cylindrical blind hole 2-2 that is slidably connected with the first shaft part 1-1 and is airtightly fitted; the airtight air chamber 4 is preferably composed of the first shaft part 1-1 and the cylindrical The first air chamber 4-1 formed between the blind holes 2-2, the first air chamber communicated with the first air chamber 4-1 and formed by the axial hole axially arranged along the first shaft part 1-1. Two air chambers 4 - 2 and a third air chamber 4 - 3 formed by radial holes communicated with the second air chamber 4 - 2 and arranged radially along the upper support plate 1 are formed. In the present invention, the airtight air cavity 4 can also be formed only by the first air cavity 4 - 1 formed between the first shaft portion 1 - 1 and the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com