Water-cooled magnetorheological soft start device

A magneto-rheological and soft-start technology, applied in the field of mechanical power transmission, can solve the problems of poor heat dissipation, small transmission power, and large slip power, etc., and achieve the effects of compact structure, lower working temperature, and wider speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

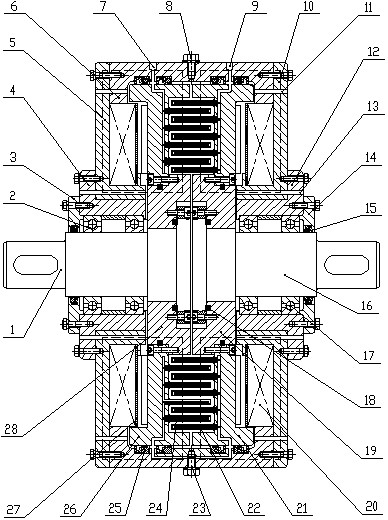

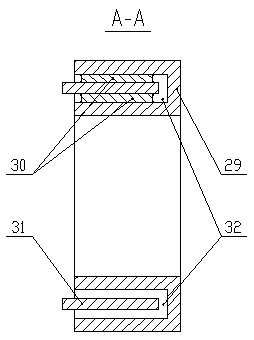

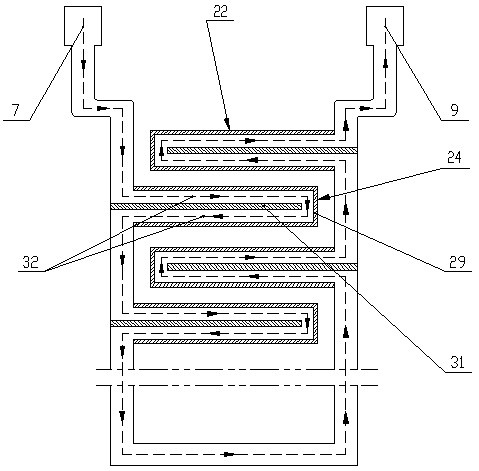

[0017] Such as Figure 1-6 As shown, a water-cooled magneto-rheological soft starter adopts the structure of the main and driven rotors, including the driving shaft 1, the driven shaft 16, the driving cylinder 24, the driven cylinder 22, the excitation coil 20, and the yoke 5 , 10, magnetic shell 6, bearing 2, 17 and sealing device 15, 18, 25, a plurality of main and driven cylinders 24, 22 are inserted in the gap between the main and driven cylinder sleeves 26, 21 respectively, the main 1. Driven cylindrical sleeves 26, 21 are respectively connected with left and right magnetically conductive shaft sleeves 28, 19 and main and driven shafts 1, 16 by screws, and sealing measures are arranged at the joints, left and right magnetic yokes 5, 10 is fixed together with the magnetic conduction shell 6, and the left and right yokes 5 and 10 are fixed with an excitation coil 20 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com