Rod carrying monitoring system for drill rod of rotary drilling machine

A technology of monitoring system and drill pipe, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., which can solve the problems of power head and drill pipe damage, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

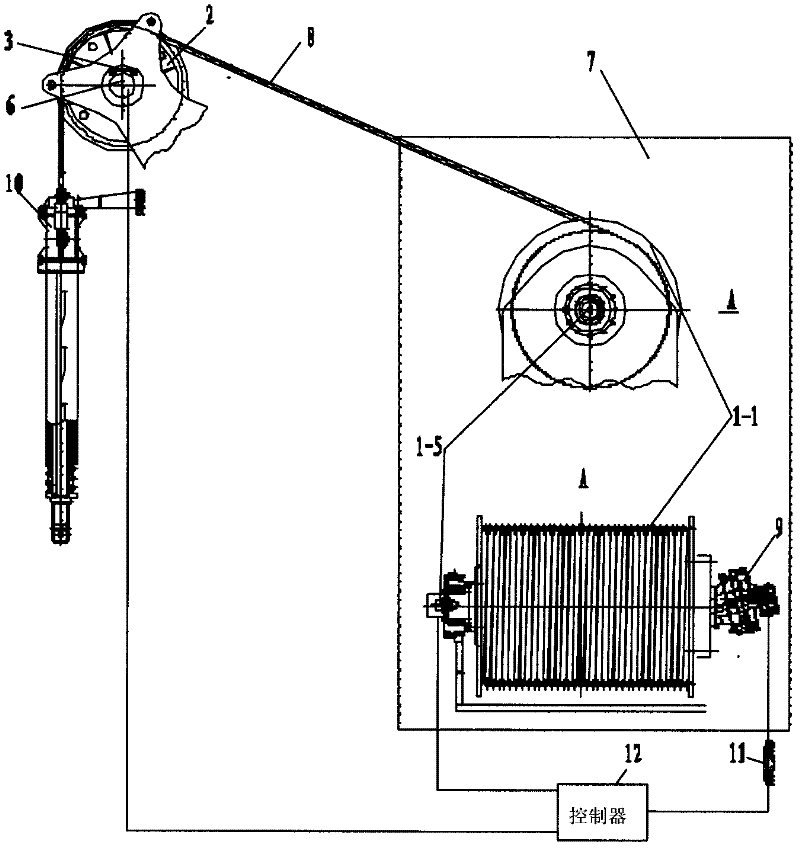

[0020] Embodiment 1: The main winch system 7 of the rotary drilling rig includes the main roll reel 1-1, the steel wire rope 8, the main roll motor 9 and the main roll pulley 2, and the mast is installed on the traveling main engine. On the front side of the mast, the upper end of the mast is connected with the main roll pulley 2, and the main roll drum 1-1 is installed on the traveling host, and the main roll motor is located on one side of the main roll drum, and the steel wire rope 8 of the main winch system 7 One end is wound on the main coil drum 1 - 1 , and the other end of the wire rope 8 is connected with the drill pipe 10 through the main coil pulley 2 .

[0021] The monitoring system is composed of a control device and a control method;

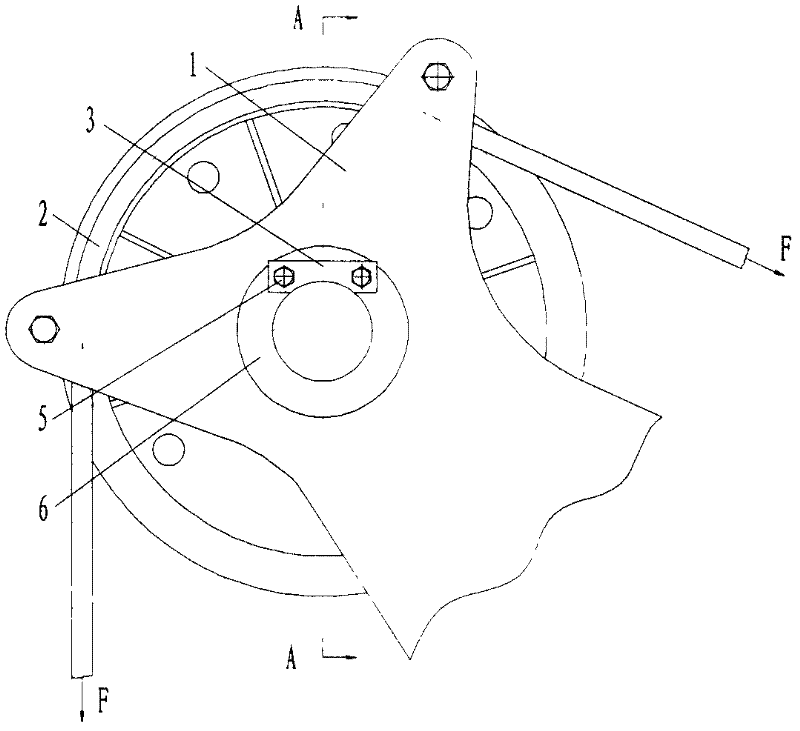

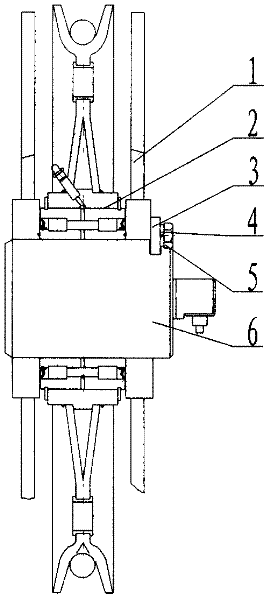

[0022] Described control device is made up of pin shaft sensor 6, sounding encoder 1-5, controller 12, pilot solenoid valve 11, main winch system 7 and each connecting wire, and pin shaft sensor 6 is connected on the main winding pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com