Novel steel tube scaffold

A technology of scaffolding and steel pipes, which is applied in the connection of scaffolding, building structure support, building structure support, etc., can solve the problems of potential safety hazards, limited application range, and no connection head, etc., to eliminate potential safety hazards, expand the scope of application, and prevent mutual detachment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

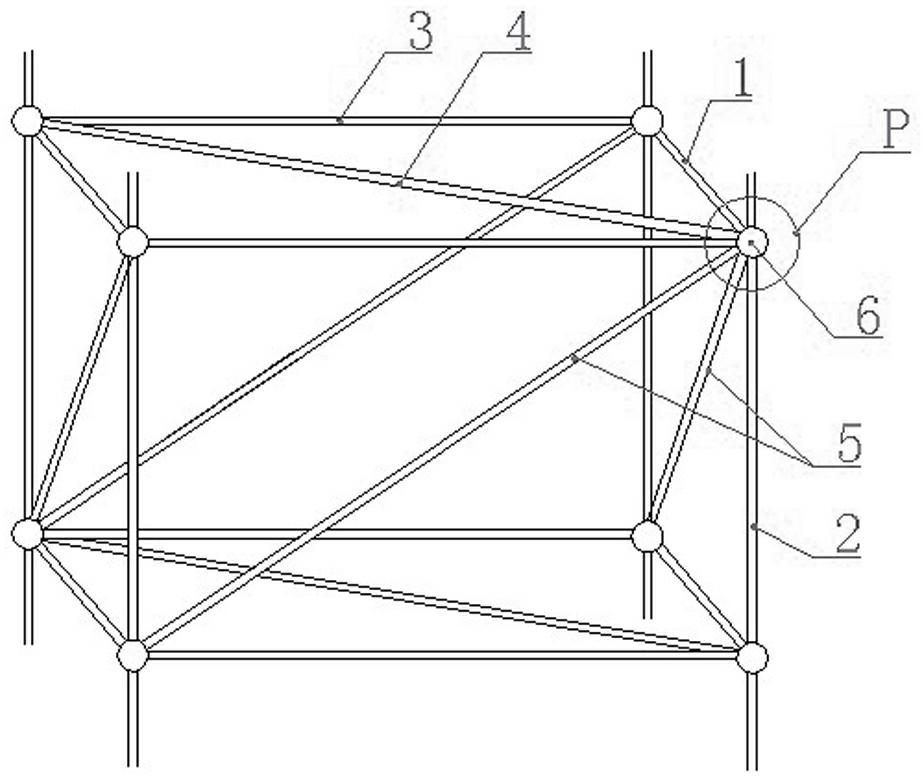

[0029] see figure 1 , a new type of steel pipe scaffolding in the present invention, comprising a riser 2, a horizontal horizontal pipe 3, a horizontal vertical pipe 1, a horizontal inclined pipe 4, a vertical inclined pipe 5 and a connecting piece 6, the standing pipe 2 connects with the horizontal horizontal pipe through the connecting piece 6 3. The horizontal longitudinal pipe 1, the horizontal inclined pipe 4 and the vertical inclined pipe 5 are connected into a multi-layer frame structure.

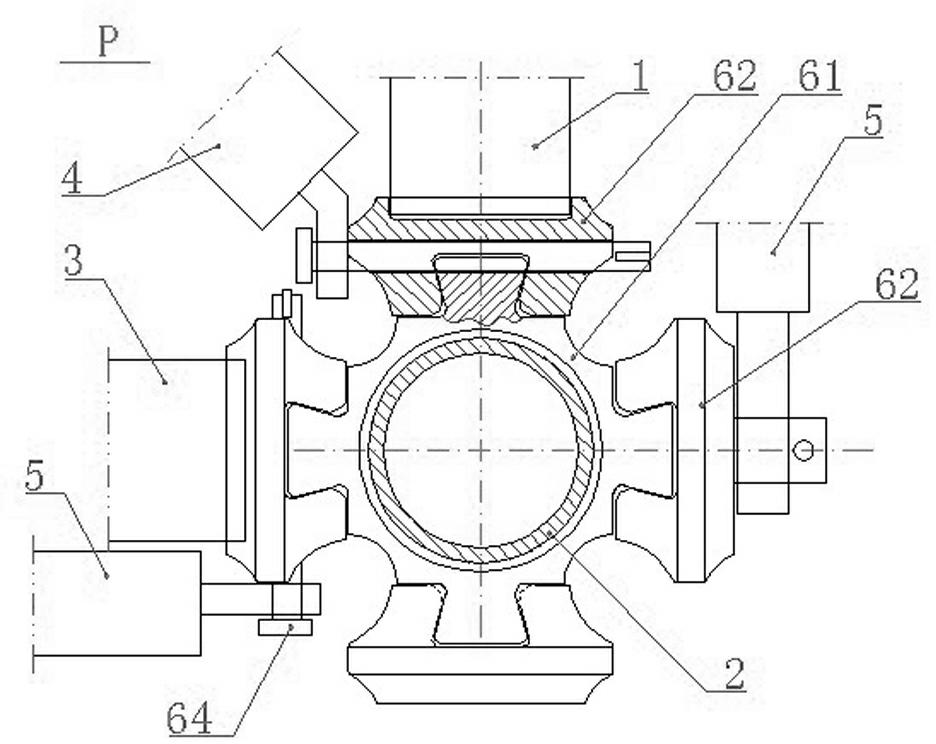

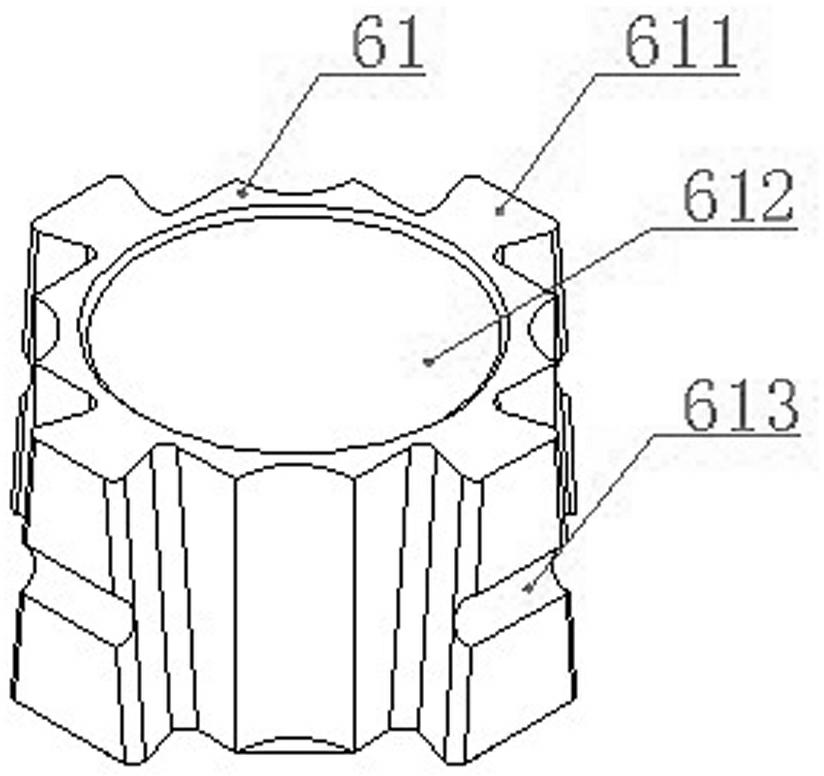

[0030] see Figure 2-Figure 15 , the connecting piece 6 includes a sleeve 61 and a vertical pipe joint 62, four trapezoidal keys 611 uniformly distributed along the circumference are arranged on the outer peripheral surface of the sleeve 61; An annular socket 622 and a trapezoidal groove 621 matched with the trapezoidal key are provided. During use, the central hole 612 of the sleeve 61 is placed on the standpipe 2 and welded, the annular socket platform 622 of the vertical pipe jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com