Blended yarns of mercerized wool, chinlon and anti-pilling acrylic fibers and preparation method thereof

A technology of anti-pilling acrylic fiber and blended yarn, which is applied in the direction of yarn, textile and paper making, to achieve the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A blended yarn of mercerized wool, nylon and anti-pilling acrylic fiber, composed of mercerized wool fiber, nylon fiber and anti-pilling acrylic fiber, the blending weight percentage of mercerized wool fiber, nylon fiber and anti-pilling acrylic fiber is 30:40 : 30. The mercerized wool fiber is mercerized Australian Merino wool fiber with an average length of 51mm and a fineness of 18.5μm; the length of nylon fiber and anti-acrylic fiber is 38mm and the fineness is 0.167Tex (1.5D).

[0042] The preparation method of above-mentioned yarn, comprises the following steps:

[0043] a. and Mao

[0044] The mercerized wool fiber, nylon fiber and anti-pilling acrylic fiber are respectively wetted and maintained, and then opened and mixed.

[0045] When respectively accumulating moisture and maintaining health, add water, antistatic agent and wool oil to the mercerized wool fiber, and keep the health for 24 hours; add water and antistatic agent to the nylon fiber, and keep the...

Embodiment 2

[0066] A blended yarn of mercerized wool, nylon and anti-pilling acrylic fiber, composed of mercerized wool fiber, nylon fiber and anti-pilling acrylic fiber, the blending weight percentage of mercerized wool fiber, nylon fiber and anti-pilling acrylic fiber is 50:30 : 20. Mercerized wool fiber is mercerized Australian Merino wool fiber. The length and fineness of each fiber are the same as in Example 1.

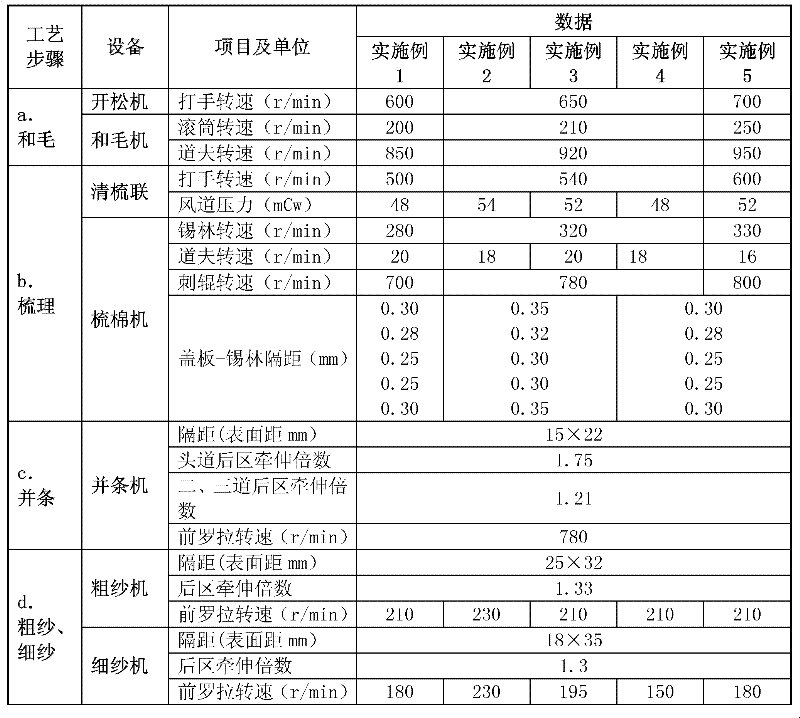

[0067] The preparation method of the above-mentioned yarn is basically the same as the steps of Example 1, the difference being that there are no doubling, two-for-one twisting and ply yarn winding steps. The technological requirements of each equipment are shown in Table 2, and the technical performance indicators of semi-finished products and finished products are shown in Table 3.

[0068] In wool blending, carding, drawing and roving steps, the relative humidity is 75%; in the spinning step, the relative humidity is 65%; in the doubling and winding steps, the relative ...

Embodiment 3

[0070] A blended yarn of mercerized wool, nylon and anti-pilling acrylic fiber, composed of mercerized wool fiber, nylon fiber and anti-pilling acrylic fiber, the blending weight percentage of mercerized wool fiber, nylon fiber and anti-pilling acrylic fiber is 40:30 : 30. Mercerized wool fiber is mercerized Australian Merino wool fiber. The length and fineness of each fiber are the same as in Example 1.

[0071] The preparation method of the above-mentioned yarn is basically the same as that of Example 1, except that in the doubling and two-for-one twisting steps, three single yarns are combined and processed into strands. The technological requirements of each equipment are shown in Table 2, and the technical performance indicators of semi-finished products and finished products are shown in Table 3.

[0072] In wool blending, carding, drawing and roving steps, the relative humidity is 70%; in the spinning step, the relative humidity is 60%; in the doubling and winding ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com