Method for preparing ethylene from calcium carbide through wet process

A calcium carbide and wet process technology, applied in the direction of calcium carbide composition of generators, parts of acetylene gas generators, acetylene generators, etc., can solve the problems of high reaction temperature and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

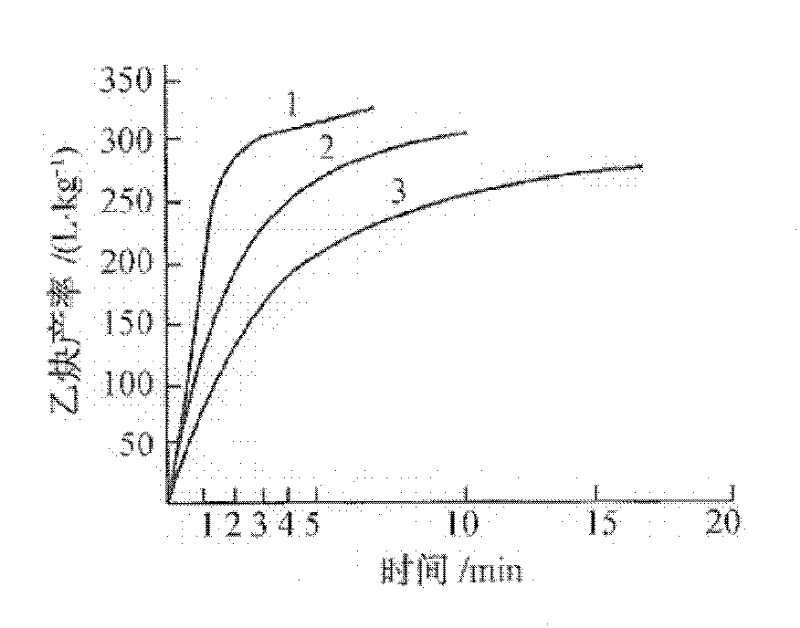

[0037] Using quicklime and coke as raw materials, sticking and sintering with electrode paste to form electrodes, the raw materials are melted at a high temperature of 2000℃ in an electric furnace to generate CaC2. 1kg of calcium carbide needs to be added with 10kg of water, see details figure 1 .

Embodiment 2

[0039] Using quicklime and coke as raw materials, sticking and sintering with electrode paste to form electrodes, the raw materials are melted at a high temperature of 2500℃ in an electric furnace to generate CaC2. 1kg of calcium carbide needs to be added with 20kg of water, see details figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| sublimation point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com