Gas-liquid exchange type liquid lithium lead alloy bubbler

A gas-liquid exchange and bubbler technology, which is applied in the field of fusion reactor liquid cladding, can solve the problems of difficult sampling, high cost, and cumbersome measurement process, and achieve obvious effects, good high-temperature sealing performance, and accurate solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

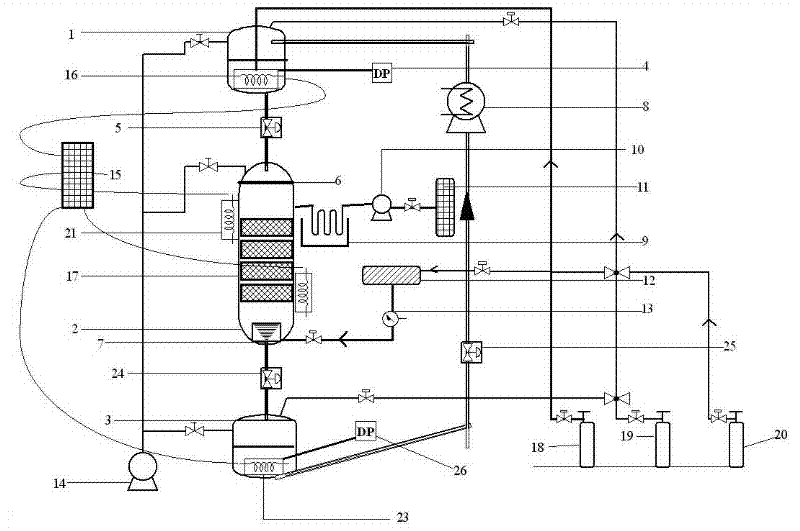

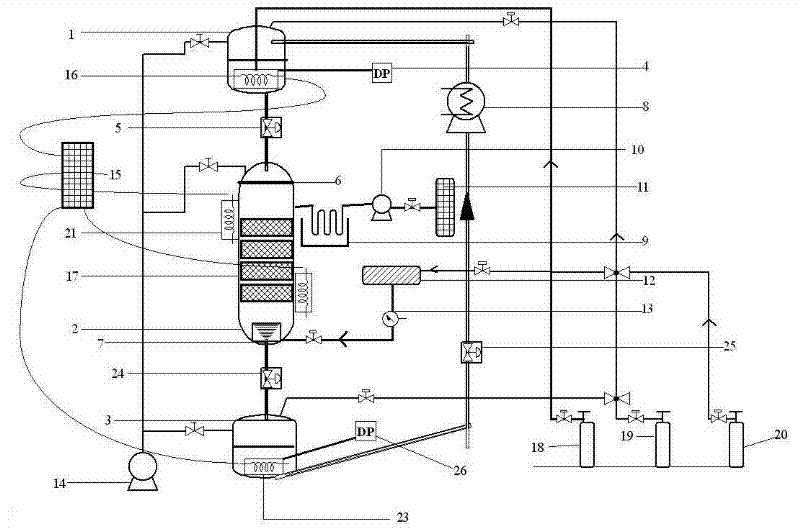

[0013] figure 1 It is a structural schematic diagram of the gas-liquid exchange type liquid lithium-lead alloy bubbler of the present invention. figure 1 A gas-liquid exchange type liquid lithium-lead alloy bubbler of the present invention includes two parts, a main circuit system and an auxiliary system; the main circuit system includes a lithium-lead saturator 1, a packed tower 2, a lithium-lead collector 3, and a gas circuit and a liquid flow path, wherein the liquid flow path includes a high temperature pipeline, a high temperature valve and a lithium-lead electromagnetic pump 8; the auxiliary system includes a temperature control instrument 15 and a vacuum pump 14. The upper part of the main circuit system is provided with a lithium-lead saturator 1, the packed tower 2 is provided in the middle of the main circuit system, and the lithium-lead collector 3 is provided in the lower part of the main circuit system. A first heater 16 and a sensor I4 are provided in the lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com