Vacuum circulative radiating system for electric driver of electric vehicle

A motor driver and heat dissipation system technology, applied in the field of electric vehicles, can solve the problems of low heat dissipation efficiency, inability to reduce the machine to ambient temperature or below, and inability to cope with the heat dissipation requirements of power equipment, so as to achieve heat dissipation and prolong service life. , the effect of reducing the conditions of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

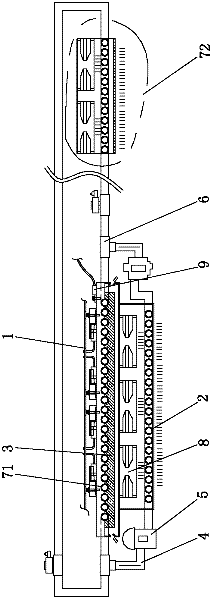

[0018] like figure 1 As shown, the present invention provides a vacuum cycle heat dissipation system for electric vehicle motor drivers, including an intelligent control circuit 1, a condenser 2, a heat insulation layer 3, a refrigerant pipeline 4, a variable speed compressor 5, a three-way solenoid valve 6 and two evaporators 71, 72, wherein, the heat-absorbing surface of the evaporator 71 is attached to a high-power heating device, and the heat-absorbing surface of the evaporator 72 is arranged in the compartment; The heat-dissipating surface, the other side is in contact with the heat-absorbing surface of the condenser 2; the refrigerant pipes 4 are respectively distributed between the heat-insulating layer 3 and the heat-dissipating surfaces of the two evaporators 71 and 72, and the internal movement of the refrigerant is used to fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com